Production technology and device of galvanized welded steel pipe

A production process and technology for welding steel pipes, which are applied in hot-dip plating process, metal material coating process, coating and other directions, which can solve the problems of cumbersome steel pipes and zinc film in galvanizing pools, and achieve convenient operation and easy galvanizing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

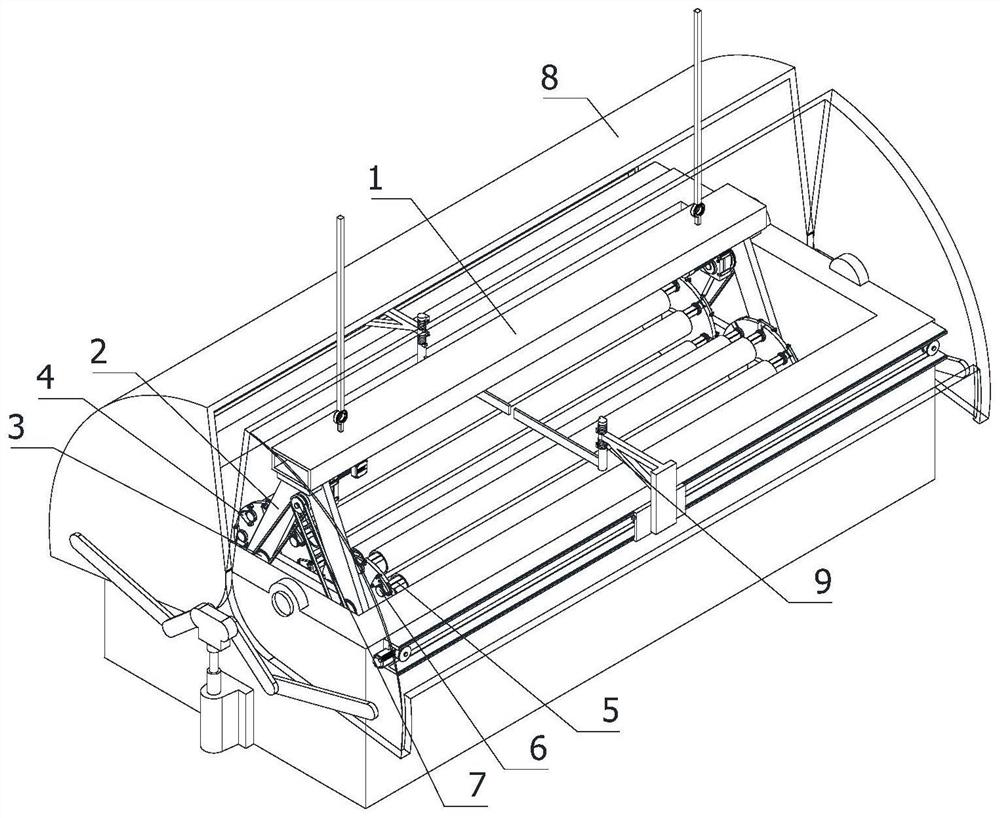

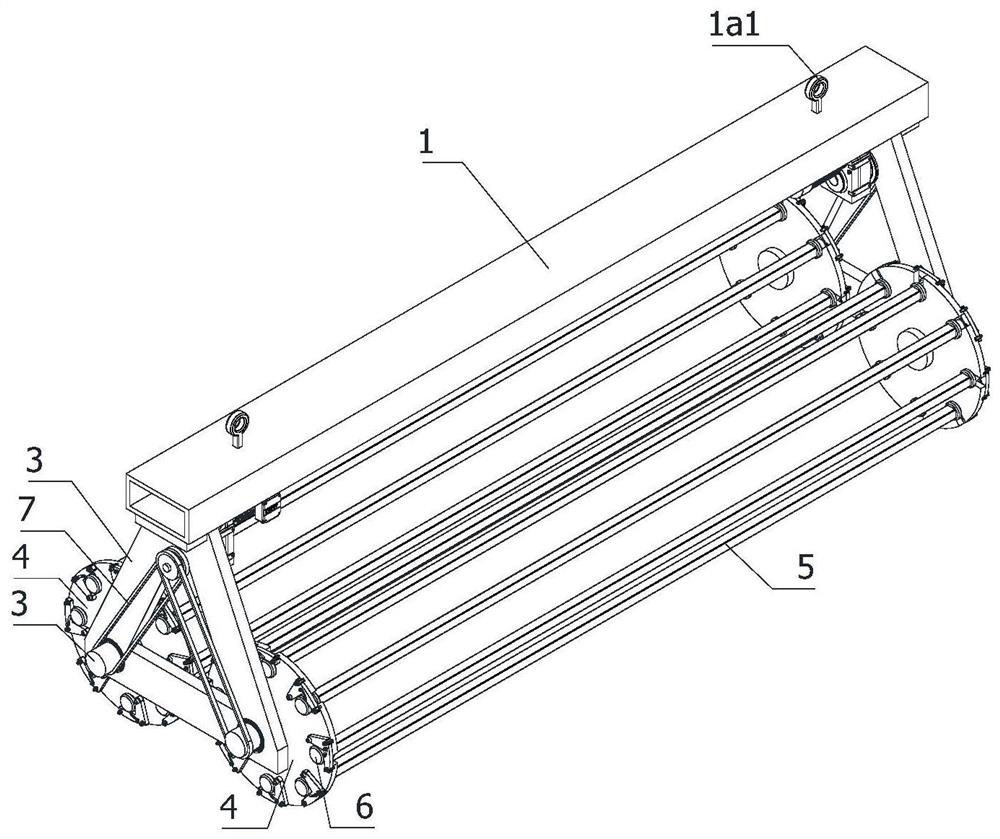

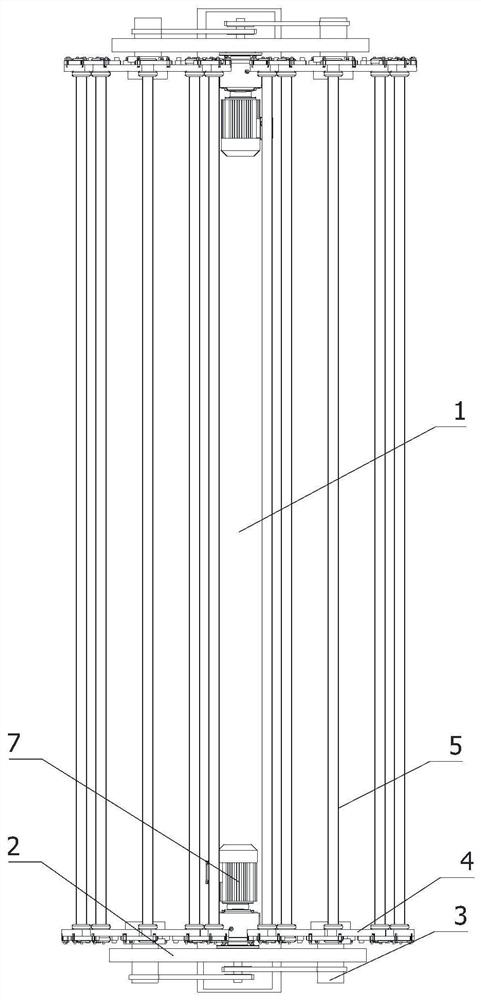

[0048] refer to figure 1 Shown, a kind of production technology of galvanized welded steel pipe comprises the following steps,

[0049] Step 1: Suspension horizontally, suspend the rigid pipe horizontally on the rotary hanger, and fix the two sides of the top of the hanger through the suspension machine;

[0050] Step 2: pickling, place the hanger in the pickling tank by the suspension machine until the pickling liquid is completely submerged in the steel pipe, close the upper protective cover 8 of the pickling tank, and put the steel pipe in the pickling tank for a period of time , so as to remove the oxide layer on the surface of the steel pipe, so as to facilitate galvanizing;

[0051] Step 3: Remove t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com