Foaming adhesive film capable of being printed in inkjet manner, and preparation method thereof

A technology for styrofoam and film application, which is applied in the direction of adhesives, film/sheet adhesives, coatings, etc., and can solve the problems of reducing the adhesive force of the adhesive layer and unfavorable normal use of the film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] At the same time, this embodiment also discloses the preparation method of the above-mentioned inkjet-printable styrofoam film, including the following steps:

[0044] Coating a coating 2 on one side of the substrate 1, and fixing a foamed air-guiding layer 4 on the other side;

[0045] The adhesive layer 5 is coated on the foamed air-conducting layer 4, and the release layer 6 is compounded after drying.

[0046] In this embodiment, the foamed air-guiding layer 4 is fixed directly on the substrate 1 by hot-melt bonding. In other embodiments, a layer can also be arranged between the substrate 1 and the foamed air-guiding layer 4. A pressure-sensitive adhesive layer or a hot-melt adhesive layer. Specifically, when the base material 1 is combined with the foamed air-conducting layer 4, a layer of pressure-sensitive adhesive layer or hot-melt adhesive layer is first coated on the side surface of the base material 1. After coating, After drying, the foamed air-guiding laye...

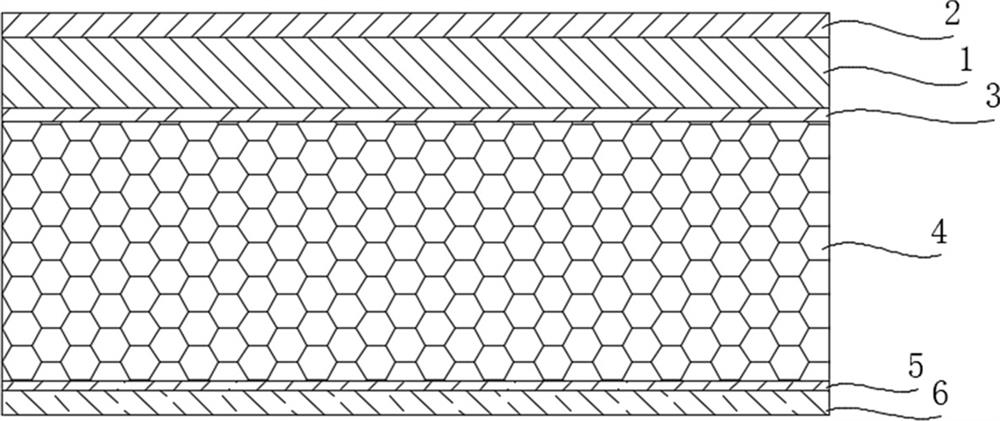

Embodiment 1

[0047] Embodiment 1: A kind of styrofoam sticking film that can be spray-painted and printed, such as figure 1 As shown, it includes a substrate 1, a coating 2 coated on one side of the substrate 1, and an adhesive layer 3 coated on the other side of the substrate 1. The adhesive layer 3 is an acrylic pressure-sensitive adhesive layer, acrylic The other side of the pressure-sensitive adhesive is pasted with a polyurethane foamed air-guiding layer 4, and the other side of the foamed air-guiding layer 4 is coated with an adhesive layer 5, which is a polyurethane pressure-sensitive adhesive layer, polyurethane A release layer 6 is compounded on the pressure-sensitive adhesive layer.

[0048]Specifically, the substrate 1 is a PP film with a thickness of 100 μm; the coating 2 has a thickness of 35 μm, and the coating 2 is composed of acrylic resin, silicon dioxide, and a mixture of calcium carbonate powder, acrylic resin, silicon dioxide, and calcium carbonate powder. The weight r...

Embodiment 2-4

[0054] Embodiment 2-4, a kind of styrofoam adhesive film that can be spray-painted and printed, such as figure 1 As shown, the difference between it and Example 1 lies in the composition of the foamed air-guiding layer 4 and its corresponding content, as shown in Table 1 for details.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com