Method for decomposing waste urea-formaldehyde resin adhesive

A technology of urea-formaldehyde resin glue and stearic acid, which is applied in chemical instruments and methods, recycling technology, chemical/physical/physicochemical processes, etc., can solve problems such as polluting the environment and difficulty in decomposing waste urea-formaldehyde resin glue, and achieve increased benefits , reduce waste and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026]A method for decomposing waste urea-formaldehyde resin glue of the present invention includes a treatment agent, the treatment agent includes the following components: acidifying agent, softening agent, penetrating agent, and the acidifying agent includes hexamethylene diamine, ammonium chloride, hexamethylene tetra One or two of amines, the softener includes stearic acid, the penetrant includes one or two of penetrant BX and penetrant T, and the mass fraction ratio of the following components is included: the acidifying agent is 55-65% , The softener is 10-25%, and the penetrating agent is 20-25%.

[0027] The specific implementation of the present invention is as follows: in the production process of the existing urea-formaldehyde resin glue, a large amount of waste urea-formaldehyde resin glue will be produced, and the waste urea-formaldehyde resin glue cannot be put into production and use, but the waste urea-formaldehyde resin glue cannot be directly discharged direc...

Embodiment 2

[0029] Based on embodiment 1, the present invention is a kind of method for decomposing waste urea-formaldehyde resin glue, and the specific realization mode of the present invention is: comprise reactor, and waste urea-formaldehyde resin glue is solidified in reactor, and formaldehyde solution is put into reactor and soaked Waste urea-formaldehyde resin glue, soaking time is 6-8 hours; after soaking, pour the treatment agent into the reaction kettle, the amount of treatment agent is 1-2 packs; then heat the reaction kettle at 70-85°C until the reaction After the reaction in the kettle is completed, no bubbles are generated, and then the temperature is lowered to below 45°C, and then the decomposed product is discharged from the reactor by opening the discharge port of the reactor. The preferred formaldehyde percentage is 37%, and then through the set Formaldehyde is convenient for soaking waste urea-formaldehyde resin glue, and then makes waste urea-formaldehyde resin glue eas...

Embodiment 3

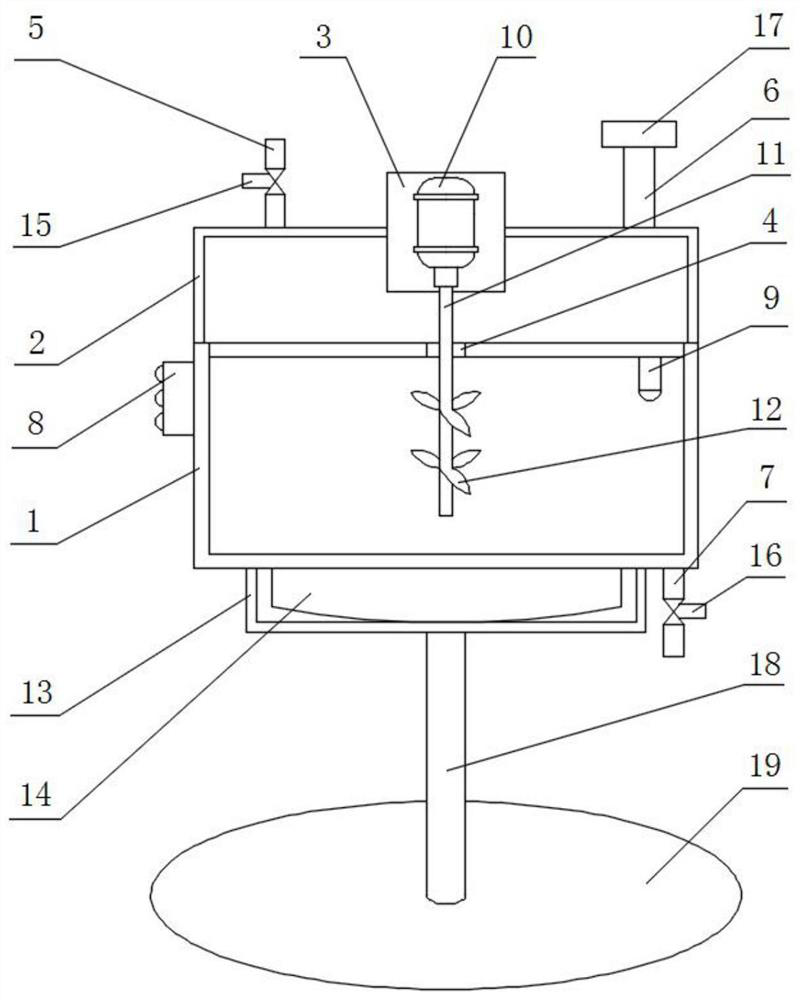

[0031] Based on the above embodiments, the present invention provides a method for decomposing waste urea-formaldehyde resin glue. The specific implementation of the present invention is: comprising a stirring device, adding formaldehyde solution into the stirring device, stirring the formaldehyde solution by starting the stirring device, and then solidifying The waste urea-formaldehyde resin glue is put into the stirring device for soaking, and the soaking time is 6-8 hours; after soaking, the treatment agent is poured into the stirring device, and the amount of the treatment agent is 1-2 packs; then the stirring device is heated up, and the temperature 70-85°C, until no bubbles are generated after the reaction in the stirring device is completed, then lower the temperature to below 45°C, and then discharge the decomposed product from the stirring device by opening the discharge port of the stirring device. The preferred percentage of formaldehyde It is 37%, and then the forma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com