Sponge type composite ecological side slope water body purification system

A water purification and slope technology, applied in the direction of biological water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problem of the lack of good treatment ideas and technologies for the tail water of rainwater sewage treatment plants, which affects sewage treatment plants Normal operation, environmental hazards of rivers and lakes, etc., to achieve the effect of reducing the content of suspended solids, large dimensions, and good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

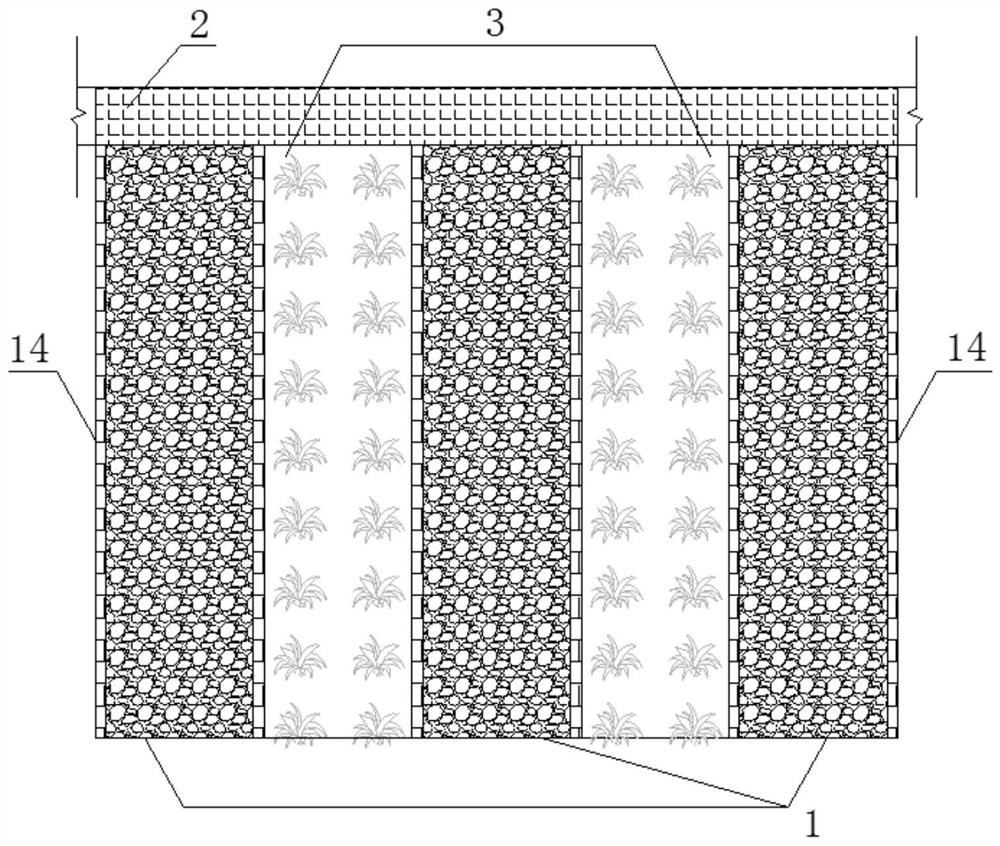

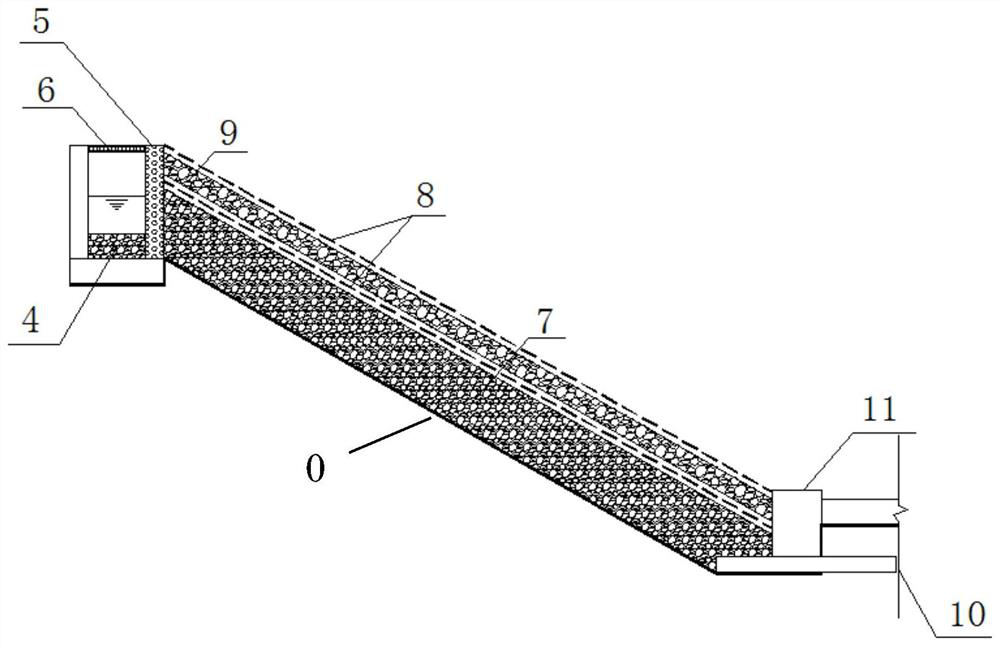

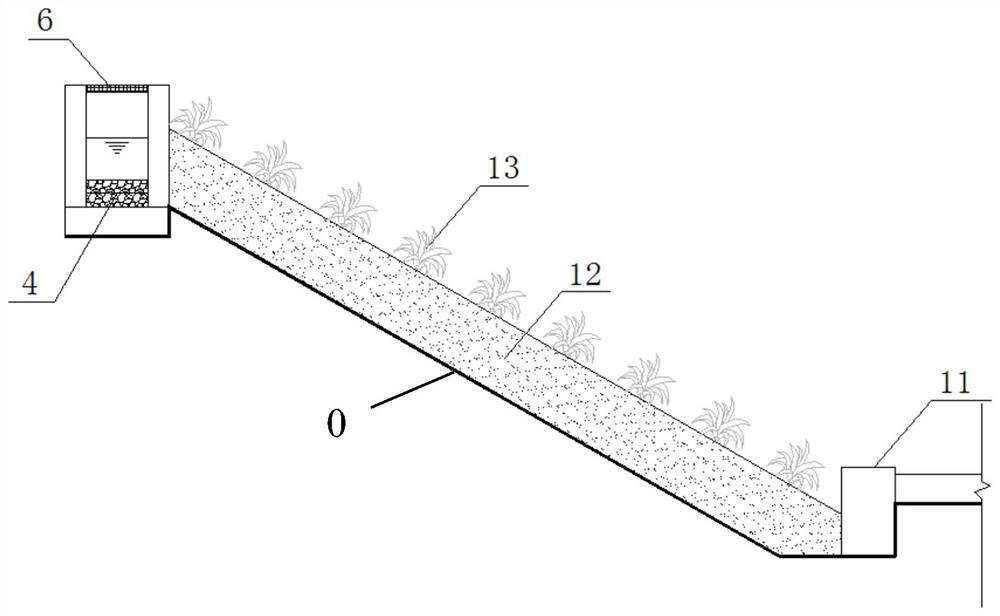

[0041] Such as Figure 1-3 As shown, a sponge-type composite ecological slope water body purification system includes: a sponge-type composite flow artificial quick-seepage ecological slope system 1 and a sponge-type wetland ecological slope system 3 arranged at intervals along the slope. Sponge compound flow artificial rapid infiltration ecological slope system 1, water distribution ditch 2 at the top of sponge type wetland ecological slope system 3; said sponge type compound flow artificial rapid infiltration ecological slope system 1 and sponge type wetland ecological slope Permea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com