Insulating sheet processing device capable of removing knife cutting tracing

A processing device and insulating sheet technology, applied in metal processing, etc., can solve problems such as low degree of automation, poor product consistency, time-consuming and labor-intensive problems, and achieve the effects of easy maintenance and cleaning, easy recycling, and improved stripping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

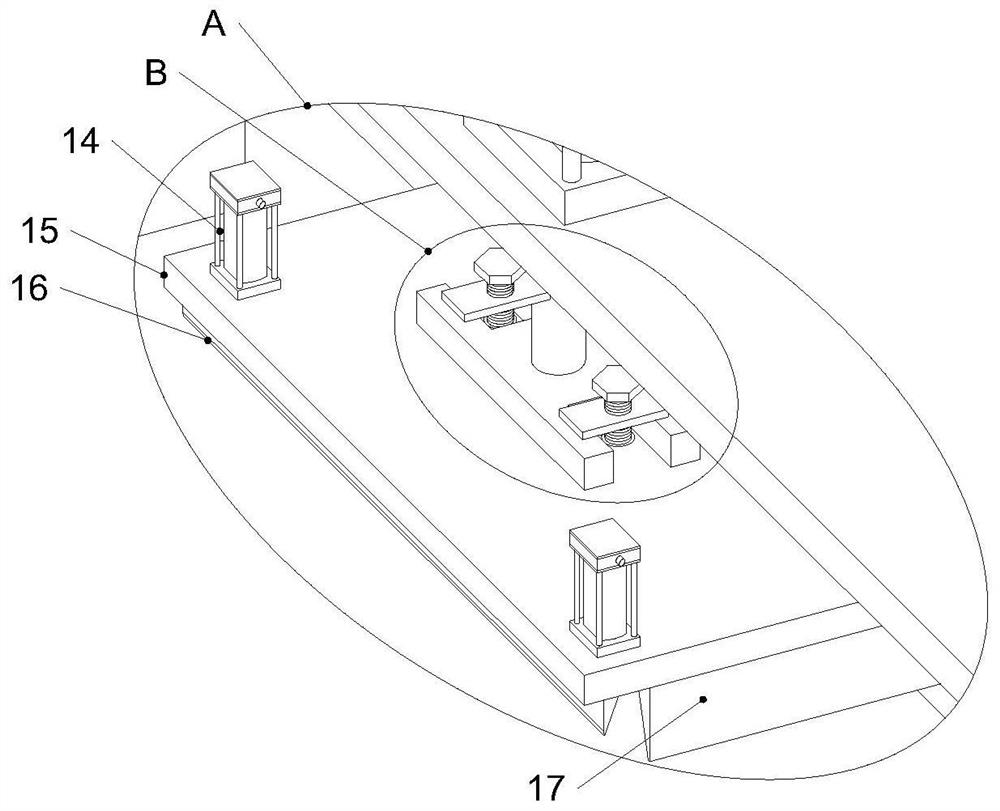

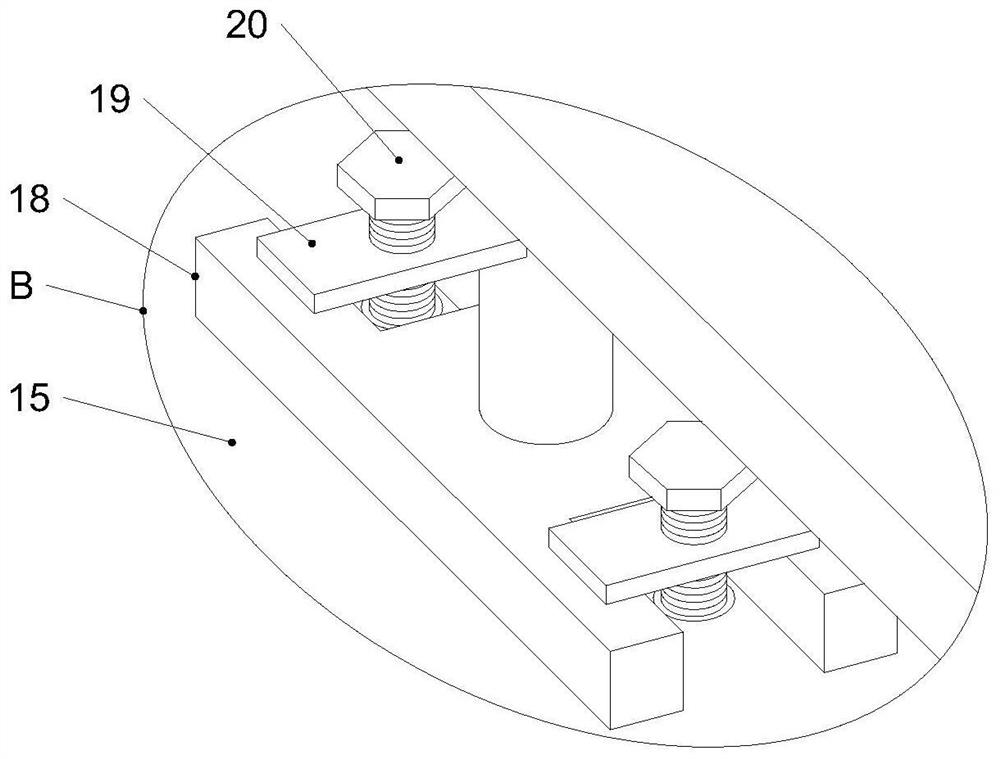

[0019] Example: such as Figure 1-3 As shown, an insulating sheet processing device capable of removing knife marks of the present invention includes a mounting base 1 on which a discharge rack 2 and a cutting table 4 are installed, and three discharge shafts 3 are installed on the discharge rack 2 , the two ends of the discharge shaft 3 are respectively installed on the surface of the discharge frame 2 through the rotation of the power shaft, and the shaft frame 6 is installed on the cutting table 4, and the shaft frame 6 is respectively installed on the two ends of the cutting table 4, and on the cutting table 4 A cutting frame 8 is installed, and a knife cutting frame 13 is installed on the cutting frame 8, a positioning frame 11 is installed on the side away from the shaft frame 6 on the cutting table 4, a hydraulic pump-12 is installed on the knife cutting frame 13, and the hydraulic pump The piston rod of -12 moves through the cutter frame 13, and is fixedly connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com