Production equipment and processing technology of a fully water-repellent polyester fusible interlining

A fusible interlining and production equipment technology, applied in biochemical fiber treatment, liquid-repellent fibers, and devices for coating liquid on the surface, can solve problems such as uneven dispensing size and uneven distribution of dispensing, Achieve the effect of improving product quality, saving workshop space and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

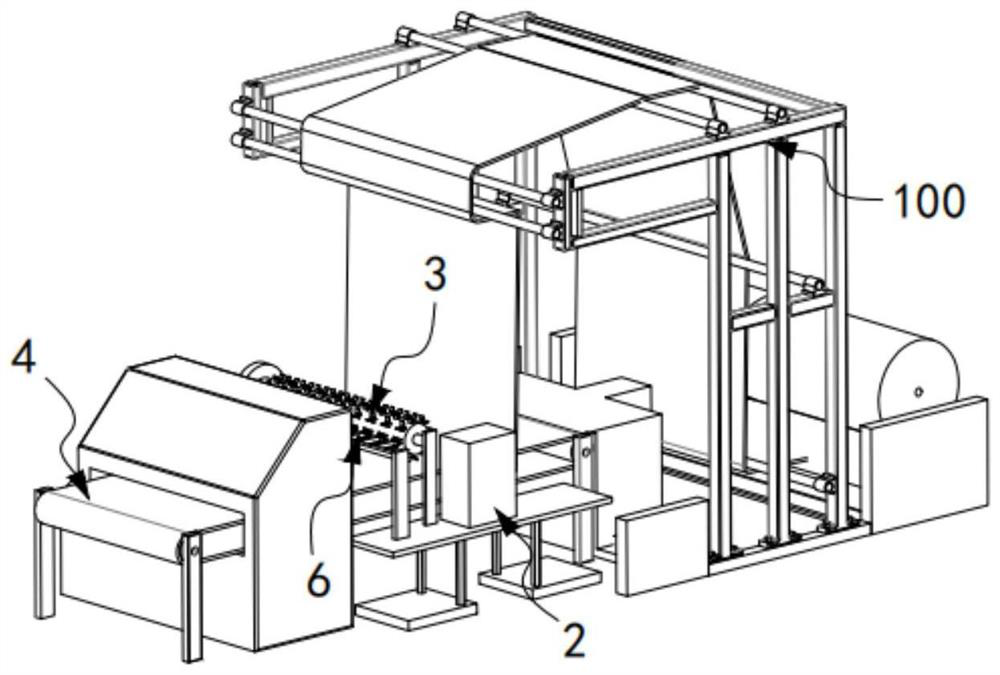

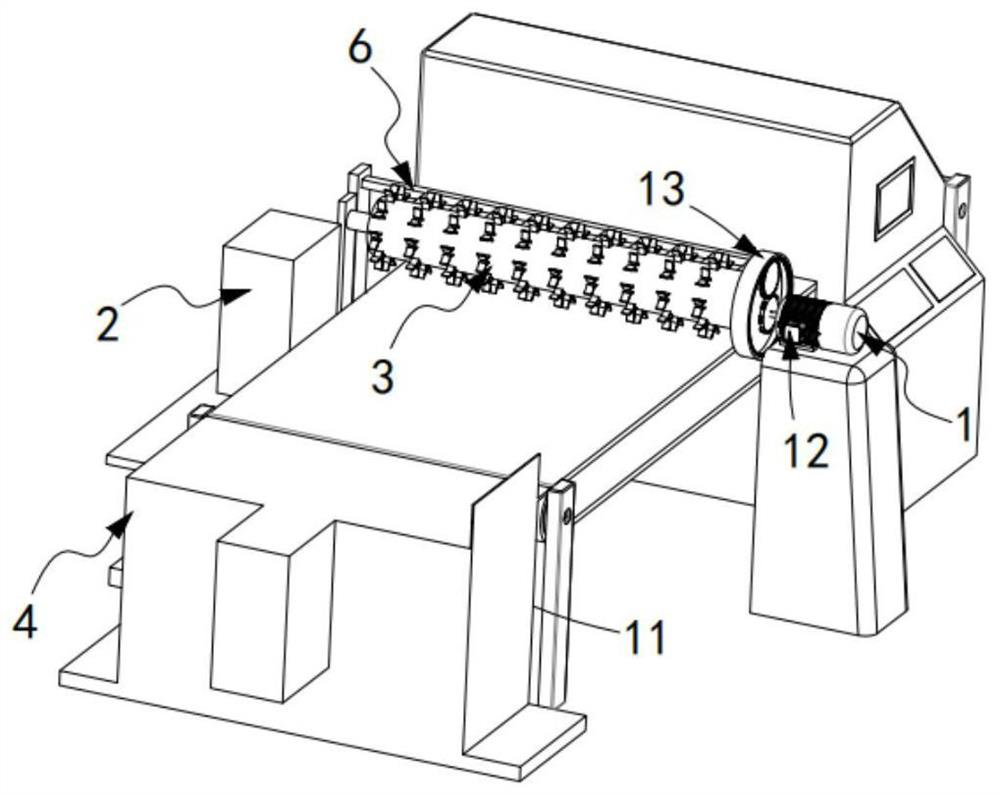

[0071] Such as figure 1 and figure 2 As shown, a fully water-repellent polyester fusible interlining production equipment, including:

[0072] A drive mechanism 1, the drive mechanism 1 includes a drive assembly 12 installed on the frame 11 and a transmission assembly 13 that is driven synchronously with the drive assembly 12;

[0073] A glue outlet mechanism 2, the glue outlet mechanism 2 includes a pulp feeding assembly 21 installed on the frame 11, a number of groups are arranged at the lower end of the pulp feeding assembly 21 and arranged at equal intervals along the length direction of the pulp feeding assembly 21 The dispensing assembly 22 and the guide assembly 23 driven by the driving assembly 12 to rotate in a circle and used to drive the dispensing assembly 22 to lift up and down in the vertical direction;

[0074] A forming mechanism 3, the forming mechanism 3 includes a support assembly 31 located outside the slurry feeding assembly 21 and coaxially arranged wi...

Embodiment 2

[0106] Such as Figure 6 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

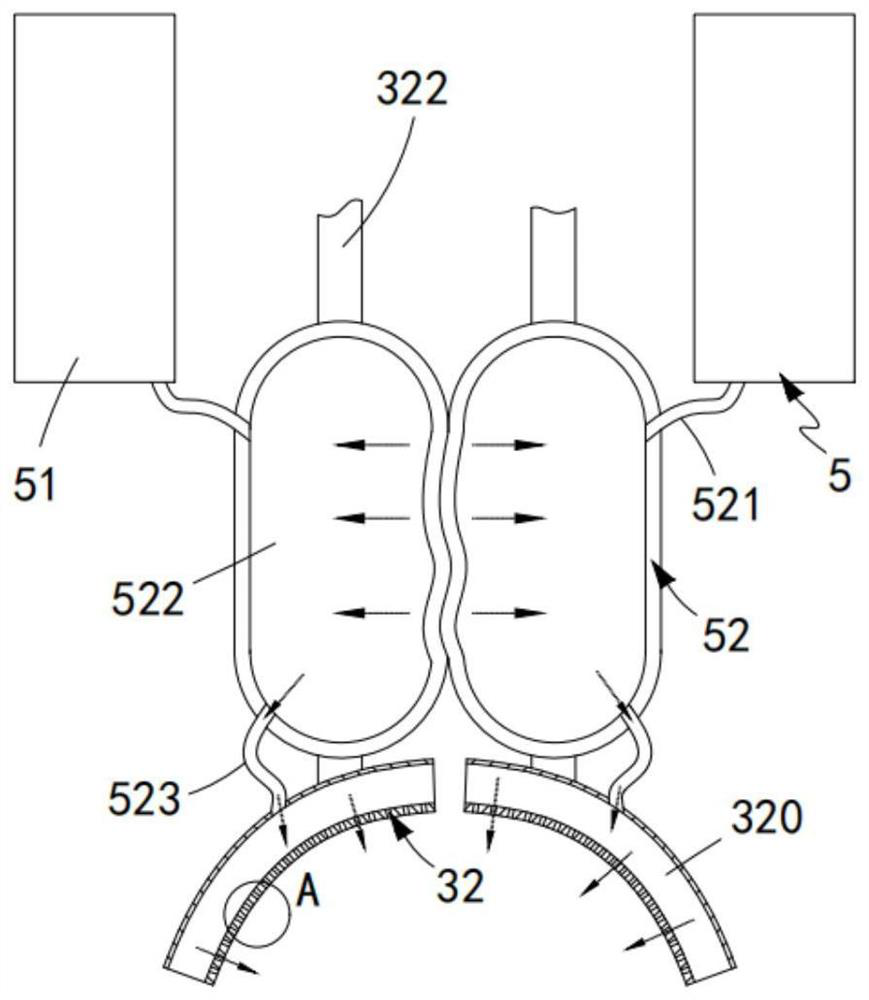

[0107] further, such as Figure 11 to Figure 14 As shown, the model components also include:

[0108] L-shaped rod 321, the horizontal part of the L-shaped rod 321 is matched with the lower end of the lifting tube 223, and a flow space 322 is formed between the L-shaped rod 321 and the limiting plate 225; and

[0109] Pull rod 323, said pull rod 323 is hinged with the lower end of the vertical part of said L-shaped rod 321, said air bag 522 is fixedly mounted on said pull rod 323 correspondingly, and two groups of said air bags 522 are arranged in discontinuous contact extrusion;

[0110] The hinge shaft 324 betwe...

Embodiment 3

[0115] further, such as Figure 21 As shown, a production process of fully water-repellent polyester fusible interlining includes a powdering process, and the powdering process includes:

[0116] Step 1, the semi-finished composite interlining is transmitted, and the interlining 10 is sequentially transported backwards under the transmission of the transmission mechanism 4;

[0117] Step 2, pulp output switching, start the drive motor a121, the drive motor a121 drives the driving gear 123 to rotate in a circle, when the rotating driving gear 123 meshes with the transmission gear 131, the transmission gear 131 drives the driven ring gear 132 to rotate, and the rotating slave gear 132 rotates. The movable ring gear 132 drives the transmission cylinder 311 to rotate, and when any one set of the tear-off assembly 32 is driven directly below the dispensing assembly 22, the tear-off assembly 32 stops driving and waits for the glue dispensing work of the dispensing assembly 22;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com