Preparation method of traditional Chinese medicinal material ultrafine powder and processed product thereof

A technology for Chinese medicinal materials and ultra-fine powder, which is applied in the field of preparation of Chinese medicinal material ultra-fine powder, can solve the problems of loss of volatile components, degradation of functional components, etc., and achieves the effects of good quality, inhibition of oxidative degradation, and reduced loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1, a kind of Yun Jie mill host, refer to the attached figure 1 , by the centrifugal fan 1, the air inlet tee 9, the cyclone dust collector 4 and the internal circulation pipe 7, the outlet 10 of the air inlet tee is connected with the air inlet of the centrifugal fan, and the second mouth of the air inlet tee is Yun The inlet 2 of the clean mill host, and the internal circulation pipe 7 connect the air outlet 8 of the centrifugal fan with the air inlet 6 of the cyclone dust collector. The exhaust outlet of the device is the outlet 5 of the main engine of the Yunjie Mill.

[0032] The cyclone dust collector 4 in the host machine of Yunjie Mill plays the role of classification. In order to achieve finer classification, the dust discharge port 3 of the cyclone dust collector can be set to be larger than the air discharge port 5.

[0033] In order to facilitate the realization that the ash outlet of the cyclone dust collector is larger than the air outlet, the a...

Embodiment 2

[0035] Embodiment 2, a kind of Yun Jie grinds, sees attached figure 2 , consisting of the Yunjie mill main engine 12 described in Embodiment 1 and an accessory device, the accessory device is composed of a cyclone dust collector 13, a bag filter 16 and an external circulation pipe 19, and the cyclone dust collector ash discharge interface 20 is arranged on the external circulation pipe. The air inlet of the cyclone dust collector is connected to the outlet of the main engine of the Yunjie Mill through the pipe 14, the air outlet of the cyclone dust collector is connected to the air inlet 15 of the bag filter, and the dust discharge port of the cyclone dust collector is connected to the cyclone dust removal port on the outer circulation pipe. The ash discharge interface 20 of the dust collector is connected, and the outlet of the outer circulation pipe is connected with the inlet of the main machine of the Yunjie Mill; the outer circulation pipe is also provided with a feeding ...

Embodiment 3

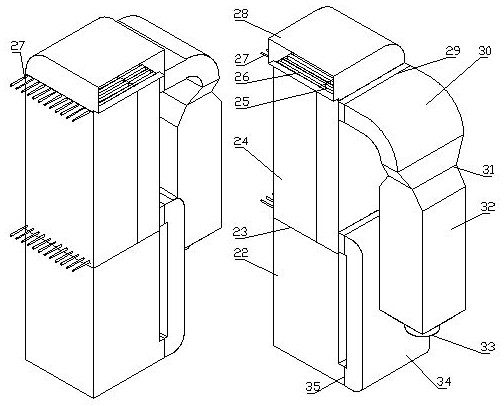

[0036] Embodiment 3, working medium supply branch, see attached image 3 , is made up of air inlet pipe 28, heat exchanger 24, condenser 22 and heater 32, and heat exchanger is made up of heat exchange branch 25 and cooling branch 26, and the heat medium channel of heat exchange branch and cooling branch enters The air outlets are brought together through the air inlet pipe 28, the inlet of the air inlet pipe is the air inlet of the working medium supply branch, and the air outlet of the heat medium channel of the heat exchange branch and the cooling branch is connected with the air inlet 23 of the condenser 22 , the exhaust outlet 35 of the condenser is connected to the inlet of the refrigerant passage of the heat exchange branch 25 through the condenser exhaust pipe 34, and the outlet 29 of the refrigerant passage of the heat exchange branch is connected to the heater through the exhaust pipe 30 of the refrigerant passage. The air inlet 31 is connected, the air outlet of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com