Moisturizing hyaluronic acid combined water-level fermentation whitening liquid extraction process

An extraction process, hyaluronic acid technology, applied in fermentation, biochemical equipment and methods, cosmetics, etc., can solve the problems of incomplete removal of protein and bacteria, complicated extraction process, and decreased dissolved oxygen, so as to reduce bacteria and protein content, increase the whitening effect, enhance the fragrance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

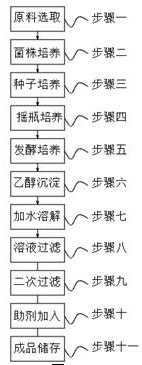

[0032] A process for extracting hydrating hyaluronic acid combined water level fermentation whitening liquid, comprising the following steps: Step 1, raw material preparation; Step 2, bacterial strain cultivation; Step 3, seed cultivation; Step 4, shake flask cultivation; Step 5, fermentation cultivation; Step 6, Ethanol precipitation; Step 7, add water to dissolve; Step 8, solution filtration; Step 9, secondary filtration; Step 10, add additives; Step 11, finished product storage;

[0033] Wherein in above-mentioned step one, at first solid culture medium, seed culture medium, fermentation medium and group A streptococcus are prepared, and seed culture medium is respectively 10 parts by weight of peptone, 10 parts of beef extract, 1 Parts of sodium chloride, 2 parts of dipotassium hydrogen phosphate and 0.3 parts of magnesium sulfate are mixed, and the fermentation medium is respectively 10 parts by weight of sucrose, 3 parts of glucose, 8 parts of peptone, 5 parts of Yeast p...

Embodiment 2

[0045] A process for extracting hydrating hyaluronic acid combined water level fermentation whitening liquid, comprising the following steps: Step 1, raw material preparation; Step 2, bacterial strain cultivation; Step 3, seed cultivation; Step 4, shake flask cultivation; Step 5, fermentation cultivation; Step 6, Ethanol precipitation; Step 7, add water to dissolve; Step 8, solution filtration; Step 9, secondary filtration; Step 10, add additives; Step 11, finished product storage;

[0046] Wherein in above-mentioned step one, at first solid culture medium, seed culture medium, fermentation medium and group A streptococcus are prepared, and seed culture medium is respectively the peptone of 15 parts, the beef extract of 20 parts, the beef extract of 3 parts by weight respectively. Parts of sodium chloride, 3 parts of dipotassium hydrogen phosphate and 0.5 parts of magnesium sulfate are mixed, and the fermentation medium is respectively 20 parts by weight of sucrose, 10 parts of...

Embodiment 3

[0058] A process for extracting hydrating hyaluronic acid combined water level fermentation whitening liquid, comprising the following steps: Step 1, raw material preparation; Step 2, bacterial strain cultivation; Step 3, seed cultivation; Step 4, shake flask cultivation; Step 5, fermentation cultivation; Step 6, Ethanol precipitation; Step 7, add water to dissolve; Step 8, solution filtration; Step 9, secondary filtration; Step 10, add additives; Step 11, finished product storage;

[0059] Wherein in above-mentioned step one, at first solid culture medium, seed culture medium, fermentation medium and group A streptococcus are prepared, and seed culture medium is respectively the peptone of 12.5 parts, the beef extract of 15 parts, the beef extract of 2 parts by weight respectively. Parts of sodium chloride, 2.5 parts of dipotassium hydrogen phosphate and 0.4 parts of magnesium sulfate are mixed, and the fermentation medium is respectively 15 parts by weight of sucrose, 6 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com