A heat-not-burn cigarette using an energy-based heat source

A heat-not-burn, heat source technology, applied in the field of tobacco, to achieve the effect of reducing the production of toxic and harmful substances and reducing the rate of heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

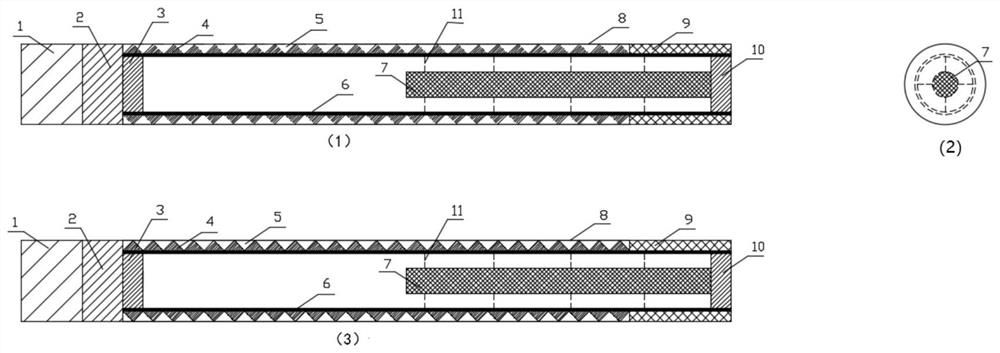

Embodiment 1

[0049] The structural design adopted in this embodiment is as follows figure 1 As shown, the filter tip 1 is located at the leftmost end of the cigarette, the cooling section 2 is connected with the filter tip, and the heat source sealing cladding metal shell structural material 4 adopts a heat source sealing cladding copper with an outer diameter of 4mm, a thickness of 0.2mm, and a length of 60mm. The shell is made, the radius of the energy-based heat source 7 is 1 mm, and the length is 20 mm. The energy-based heat source 7 is fixed in the heat source airtight cladding metal shell through the bracket 11, and glass fiber flame-retardant material 3 of appropriate thickness is filled at both ends and 10. A serrated tobacco sheet is wound on the outer layer of the heat source sealed and coated metal shell. The length of the tobacco sheet is 50 mm. The right end of the tobacco sheet is connected with a heat insulating material with a length of 10 mm. The outermost layer is covered...

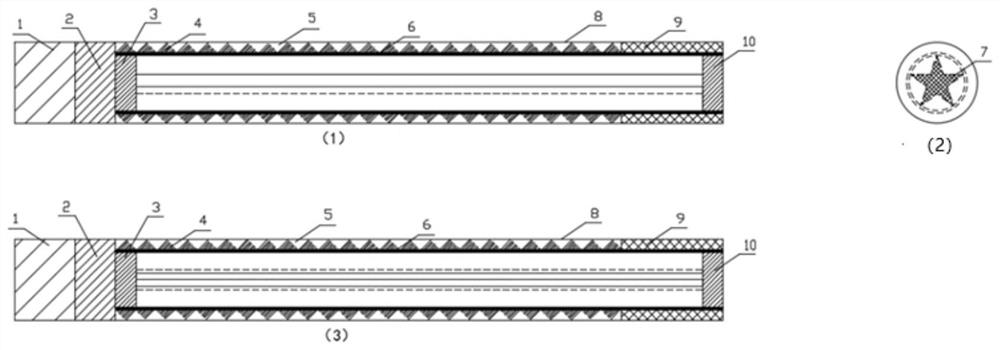

Embodiment 2

[0053] The structural design adopted in this embodiment is as follows figure 1 As shown, the specific connection method is the same as Example 1, the difference is that the heat source airtight clad copper shell adopts a closed copper tube with an outer diameter of 6mm, a thickness of 0.2mm, and a length of 60mm, and a sealed copper tube with a radius of 1mm and a length of 20mm. Energy-based heat source. Set a suitable observation point on the outer wall of the heat source airtight clad copper shell, and place a thermocouple on the corresponding observation point to record the temperature change of the heat source airtight clad copper shell outer wall. The test results show:

[0054] The highest temperature at the observation point is 313.2°C;

[0055] The average burning speed is 0.328cm / s.

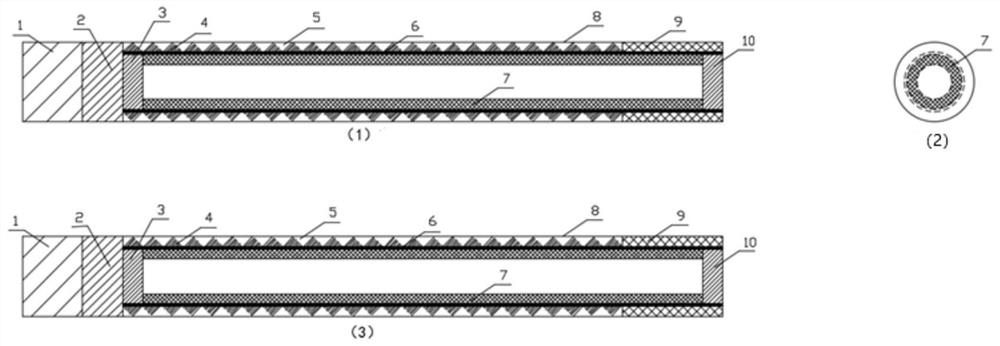

Embodiment 3

[0057] The structural design adopted in this embodiment is as follows figure 1 As shown, the specific connection method is the same as Example 1, the difference is that the outer diameter of the heat source is 6 mm, the thickness is 0.25 mm, and the length is 60 mm. The outer diameter of the heat source is 1 mm. An energy-based heat source with a length of 20 mm. Set a suitable observation point on the outer wall of the heat source airtight clad copper shell, and place a thermocouple on the corresponding observation point to record the temperature change of the heat source airtight clad copper shell outer wall. The test results show:

[0058] The highest temperature at the observation point is 283.4°C;

[0059] The average burning speed is 0.342cm / s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com