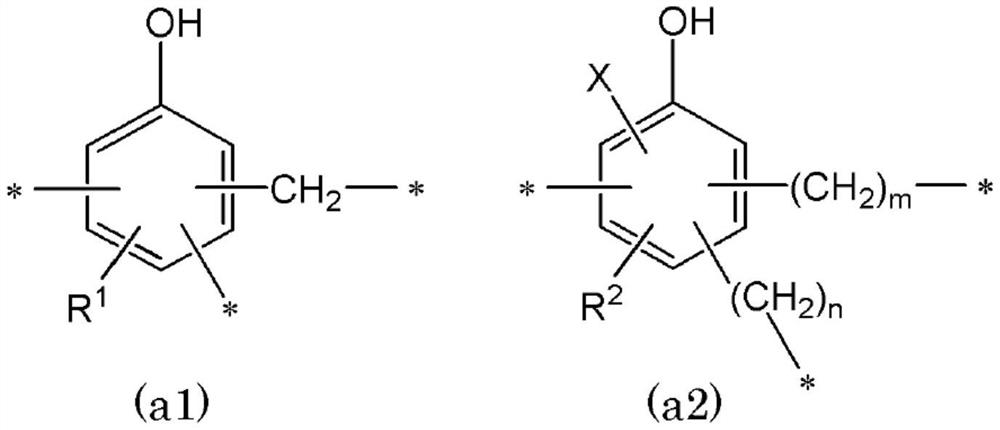

Thermosetting resin composition, prepreg, resin-coated metal foil, laminate, printed wiring board, and semiconductor package

A resin composition, thermosetting technology, used in metal layered products, manufacturing printed circuit precursors, semiconductor/solid-state device components, etc. Excellent, high elongation, high heat resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0186] Hereinafter, although an Example and a comparative example are shown and this invention is concretely demonstrated, this invention is not limited to these.

Synthetic example 1

[0187] [Synthesis example 1] Production of phenolic resin (A-1)

[0188] (Synthesis of phenolic resin (A-1-a))

[0189]In a glass flask with an inner capacity of 2 L equipped with a thermometer, a stirrer and a cooling tube, add 300 g (1.0 mol) of cardanol, 150 g of methanol, and 120 g (2.0 mol) of a 50% aqueous formaldehyde solution, and dissolve a 30% aqueous solution of sodium hydroxide in 2 hours. Drop into this mixture. Then, it heated up to 45 degreeC, and it was made to react for 6 hours. Next, 35% hydrochloric acid was added to the obtained reaction solution to neutralize sodium hydroxide, and then 1,342 g (10 mol) of o-allylphenol was added, and 1.34 g (0.1% by mass relative to o-allylphenol) was added. Oxalic acid made the system acidic, and after heating up to 100°C, the reaction was carried out for 5 hours. After washing the reaction liquid with water, excess o-allylphenol was distilled off to obtain a phenolic resin (A-1-a).

[0190] The obtained phenolic resi...

Synthetic example 2

[0204] [Synthesis example 2] Production of phenolic resin (A-1)

[0205] (Synthesis of phenolic resin (A-1-b))

[0206] 248 g (1.0 mol) of p-(4-pentylcyclohexyl)phenol, 150 g of methanol, and 120 g (2.0 mol) of 50% formaldehyde aqueous solution were added to a glass flask with an inner capacity of 2 L equipped with a thermometer, a stirrer, and a cooling tube, and the mixture was mixed with 2 A 30% aqueous solution of sodium hydroxide was dropped into the mixture after hours. Then, it heated up to 45 degreeC, and it was made to react for 6 hours. Next, after adding 35% hydrochloric acid to the obtained reaction solution to neutralize sodium hydroxide, 1,342 g (10 mol) of o-allylphenol was added, and 1.34 g (0.1% by mass relative to o-allylphenol) was added. Oxalic acid made the system acidic, and after heating up to 100°C, the reaction was carried out for 5 hours. After washing the reaction liquid with water, excess o-allylphenol was distilled off to obtain a phenolic resin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com