Intermediate film for laminated glass, laminated glass, and method for installing laminated glass

A technology for laminated glass and interlayer film, which is applied in the field of interlayer film for laminated glass and laminated glass, and can solve the problems of double images of measurement information and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9、17 and comparative example 1、3

[0328] First laminated glass part:

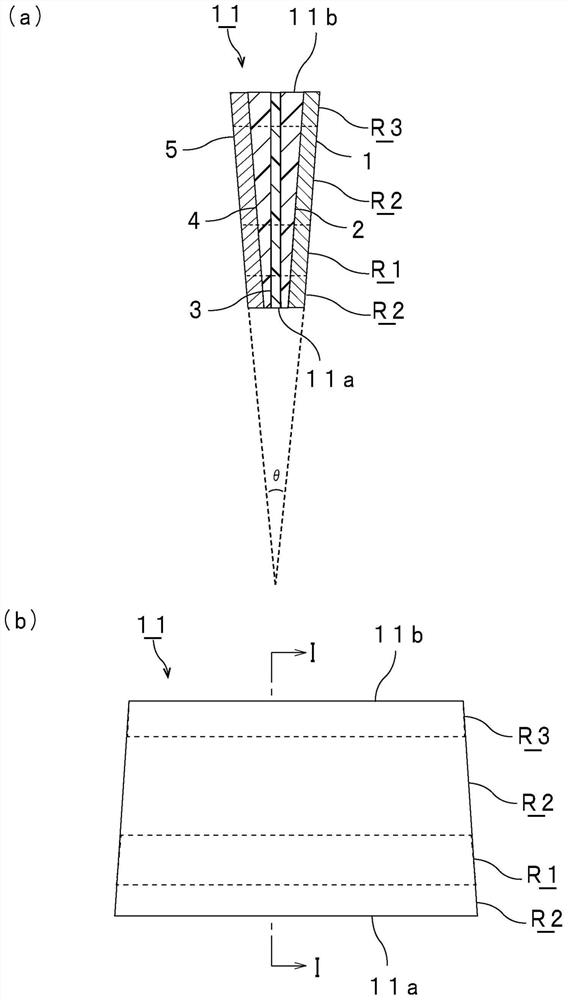

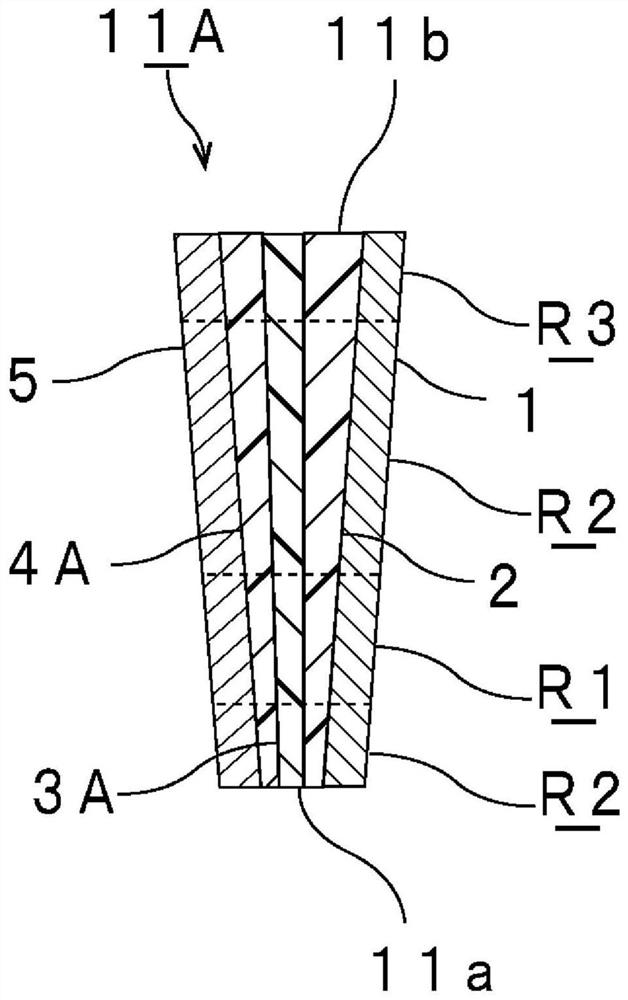

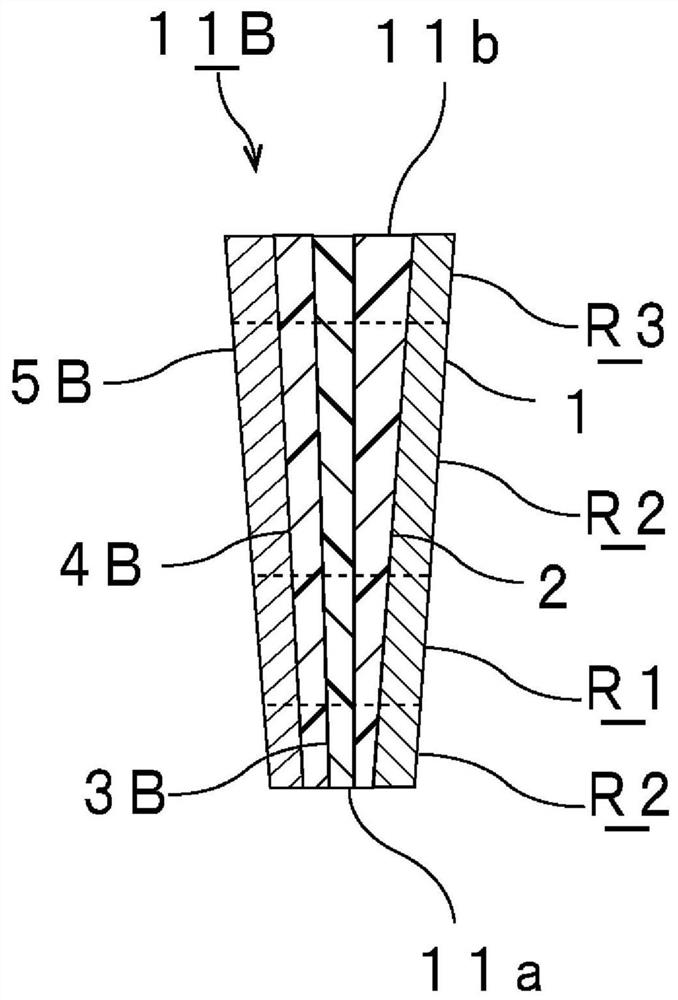

[0329] Transparent glass having thicknesses and wedge angles shown in Tables 1, 2, and 4 below was prepared. It should be noted that in the case of a wedge angle of 0 mrad, it means that the shape is a rectangle rather than a wedge.

[0330] First resin layer:

[0331] The following components were prepared and sufficiently kneaded with a mixing roll to obtain a composition for forming the first resin layer.

[0332] Polyvinyl acetal resin (average degree of polymerization 1700, hydroxyl content 30.5 mol%, degree of acetylation 1 mol%, degree of acetalization 68.5 mol%) 100 parts by weight

[0333] 40 parts by weight of triethylene glycol bis(2-ethylhexanoate) (3GO)

[0334] ITO (Indium Tin Oxides, indium tin oxide) particles (manufactured by Mitsubishimaterials) in an amount of 0.28% by weight in the obtained first resin layer

[0335] Tinuvin326 (2-(2'-hydroxy-3'-tert-butyl-5-methylphenyl)-5-chlorobenzotriazole in an amount of 0.2% by...

Embodiment 18

[0344] First laminated glass part:

[0345] Transparent glass having the thickness and wedge angle shown in Table 4 below was prepared. It should be noted that, when the wedge angle is 0 mrad, it means that the shape is not a wedge but a rectangle.

[0346] First resin layer:

[0347] The following components were prepared and fully kneaded with a mixing roll to obtain a composition A for forming the first resin layer (multilayer).

[0348] 100 parts by weight of polyvinyl acetal resin (hydroxyl content: 22 mol%, degree of acetylation: 13% by mole, degree of acetalization: 65% by mole)

[0349] Triethylene glycol bis(2-ethylhexanoate) (3GO) 65 parts by weight

[0350]Tinuvin326 (2-(2'-hydroxy-3'-tert-butyl-5-methylphenyl)-5-chlorobenzotriazole in an amount of 0.2% by weight in the obtained composition A layer, BASF "Tinuvin 326" manufactured by the company) BHT (2,6-di-tert-butyl-p-cresol) in an amount of 0.2% by weight in the obtained composition A layer

[0351] The fol...

Embodiment 10~16 and comparative example 4、5

[0365] First laminated glass part:

[0366] Transparent glass having the thicknesses and wedge angles shown in Tables 3 and 4 below was prepared. It should be noted that in the case of a wedge angle of 0mrad, it means that the shape is not a wedge.

[0367] The first resin layer and the second resin layer:

[0368] The following components were prepared and sufficiently kneaded with a mixing roll to obtain a composition for forming the first resin layer and the second resin layer.

[0369] Polyvinyl acetal resin (average degree of polymerization 1700, hydroxyl content 30.5 mol%, degree of acetylation 1 mol%, degree of acetalization 68.5 mol%) 100 parts by weight

[0370] 40 parts by weight of triethylene glycol bis(2-ethylhexanoate) (3GO)

[0371] ITO particles (manufactured by Mitsubishimaterials) in an amount of 0.28% by weight in the obtained first resin layer and the second resin layer

[0372] Tinuvin326 (2-(2'-hydroxyl-3'-tert-butyl-5-methylphenyl)-5-chlorobenzene in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com