Aluminum profile extrusion process flow data anomaly detection method and device based on isolated forest algorithm and storage medium

A forest algorithm, extrusion process technology, applied in computing, computer parts, instruments, etc., can solve the problems of inaccurate abnormal detection results and inaccurate abnormal detection of streaming data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

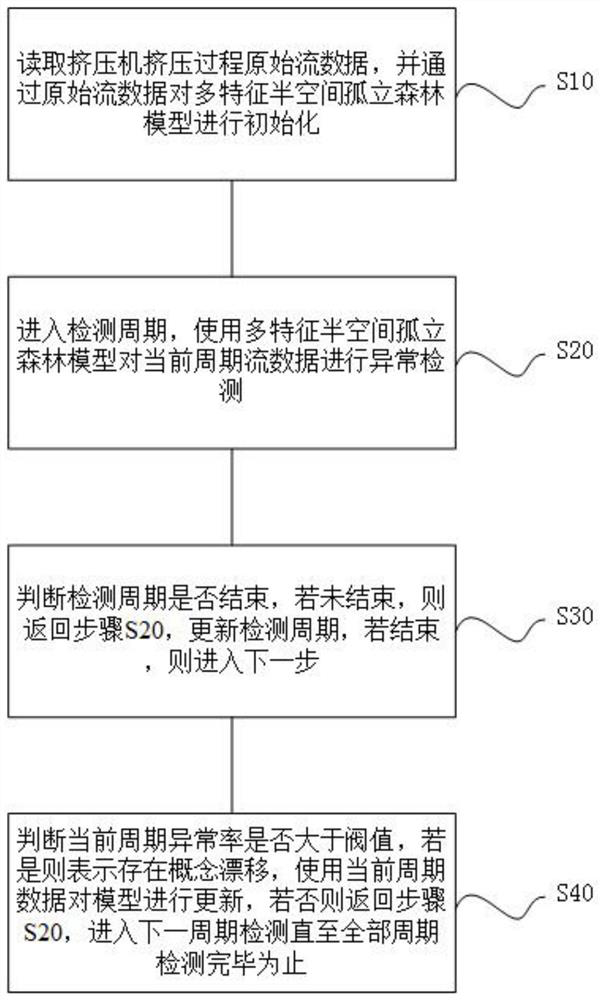

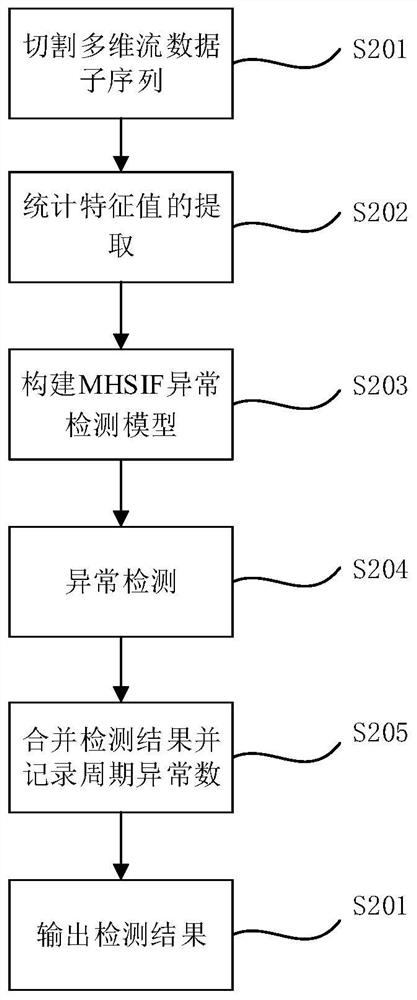

[0079] This embodiment discloses a method for detecting anomalies in aluminum profile extrusion process flow data based on the isolated forest algorithm. The method is proposed on the basis of the half-space isolated forest (HS-Trees) model, wherein the half-space isolated forest (HS-Trees ) The establishment process of the model subtree is mainly divided into two stages: subtree construction and node quality calculation. In the subtree construction stage, the value boundary of each dimension of the data is obtained, a certain dimension is randomly selected, and the midpoint of the dimension is used as the dividing point to cut the subspace. The dimension information of the subspace is updated, and each subspace is divided again, and the half-space tree is obtained through the iterative division process, as shown in Algorithm 1.

[0080] Algorithm 1 HS-Trees Subtree Construction Algorithm-BuildTree

[0081]

[0082]

[0083] In the node quality calculation stage, record...

Embodiment 2

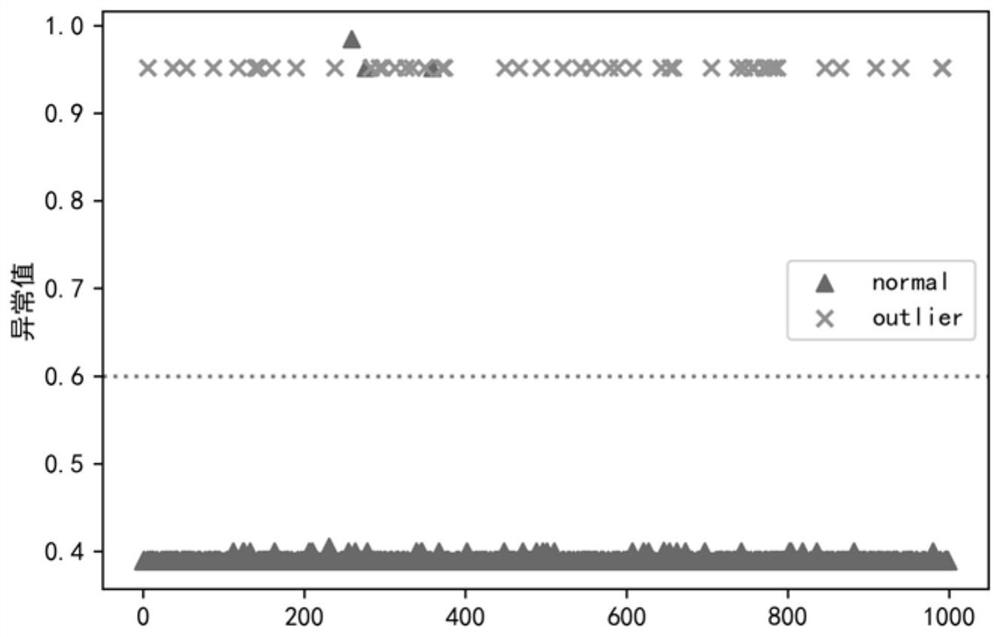

[0139] In this embodiment, the method, equipment and storage medium in Example 1 are used to carry out experiments on the extruder, and the experimental results prove that the method proposed by the present invention can not only detect in real time the abnormal state of the extruder during operation, And it has higher accuracy.

[0140] The experiment is as follows:

[0141] 1) Experimental environment and data

[0142] The environment used in the experiment of the present invention is Intel(R) Core(TM) i5-7300HQ@2.5GHz, 16GB RAM, Windows 10 64-bit system, and the algorithm is implemented using Python 3.7.

[0143] 2) Evaluation indicators

[0144] The present invention uses the three most commonly used indicators in the field of anomaly detection, namely accuracy rate, recall rate and precision rate, to verify the anomaly detection performance of the model. Among them, the correct rate indicates the proportion of the number of correct judgments by the model to the total d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com