A sliding thrust bearing with cam linkage to achieve load distribution between pads

A technology of sliding thrust bearing and linkage block, which is applied in the direction of sliding contact bearing, rotating bearing, bearing, etc., can solve problems such as unbalanced force, achieve uniform and stable transmission, meet reliability and stability, and ingenious structural design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

[0034] Any feature disclosed in this specification (including any appended claims, abstract), unless otherwise stated, may be replaced by alternative features which are equivalent or serve a similar purpose. That is, unless expressly stated otherwise, each feature is one example only of a series of equivalent or similar features.

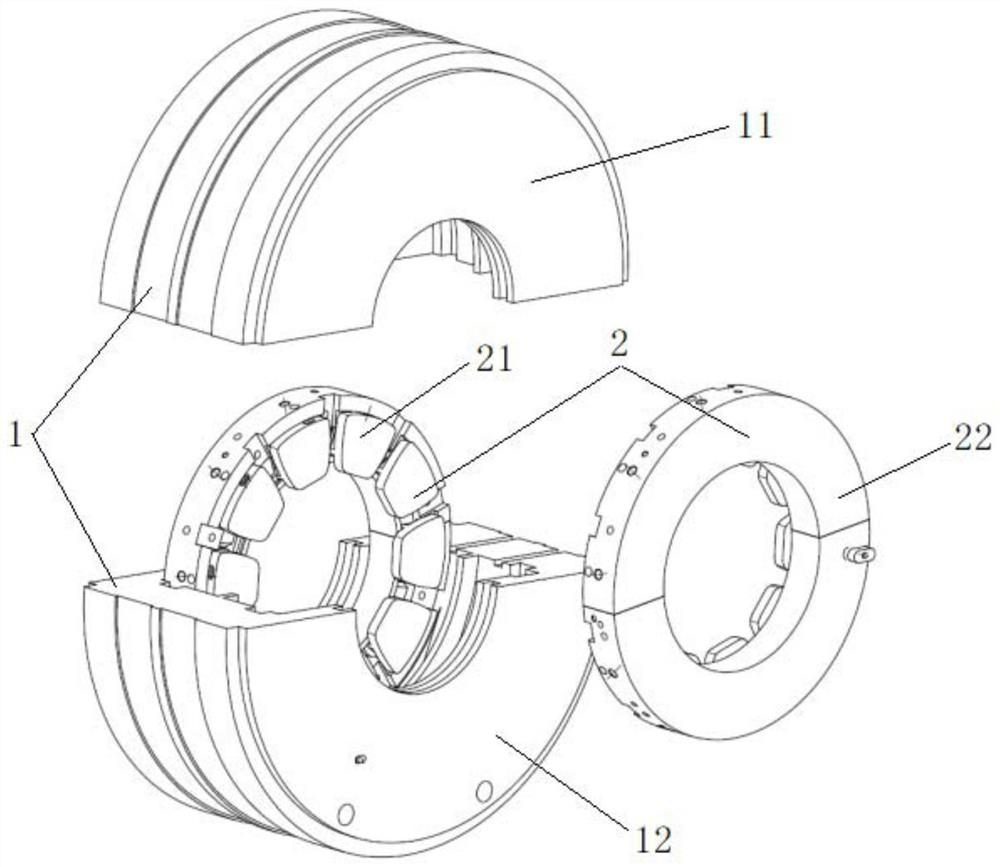

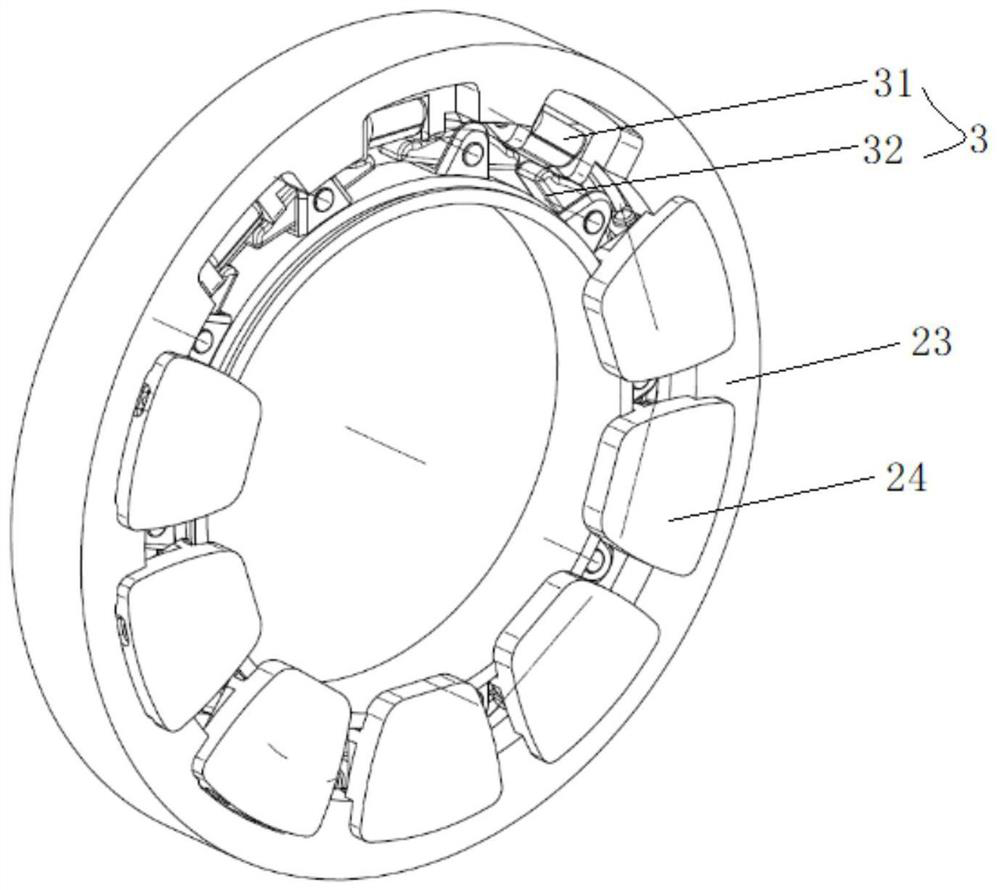

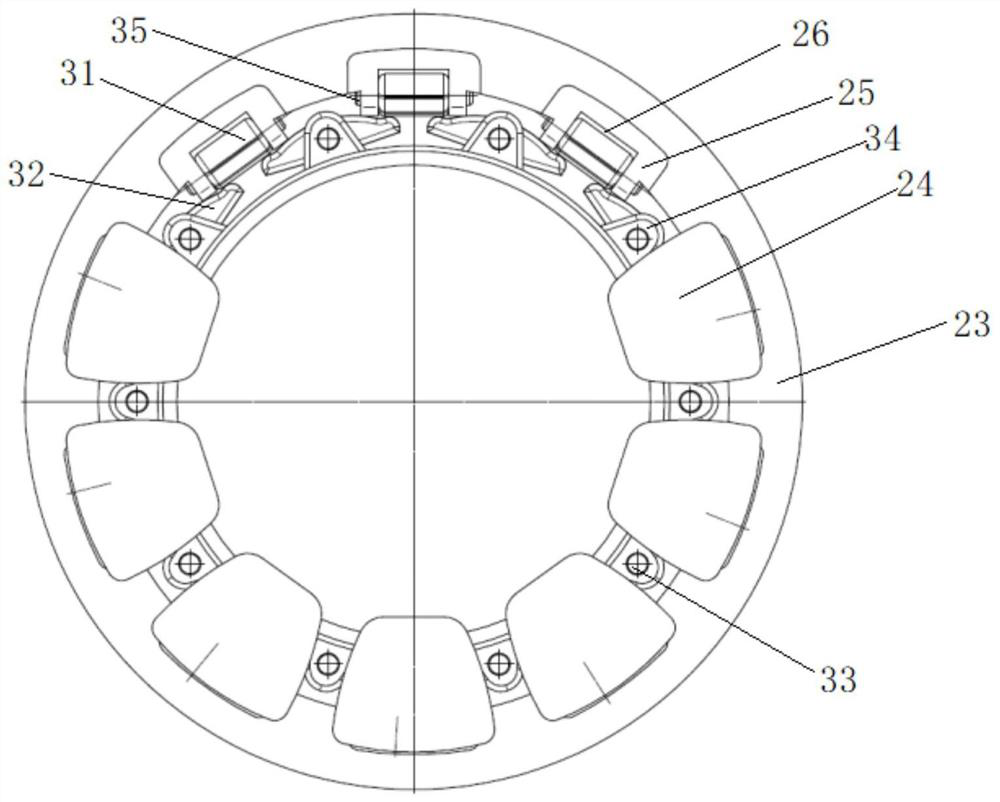

[0035] The embodiment is basically as figure 1 As shown: this embodiment provides a sliding thrust bearing that achieves uniform load distribution between pads by cam linkage, which is applied in a steam turbine to withstand the axial thrust of the rotor and limit its axial displacement; the sliding thrust bearing includes a bushing sleeve 1 and the thrust pad assembly 2, the bushing sleeve 1 includes an upper half bearing bushing 11 and a lower half bearing bushin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com