A kind of prestressed ground anchor and its method for segmental completion of horizontal well screen pipe

A prestressing and ground anchoring technology, which is applied in cementing, oil drilling, and well completion, can solve problems such as unsatisfactory effect of lifting and eliminating prestress, poor mechanical properties of loose sandstone, and insufficient safety and stability of the process, so as to improve the completion of wells. The effect of pulling the prestress, strengthening the anchoring effect, and improving the effect of the anchoring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0068] It should be noted that the structures, proportions, sizes, etc. shown in the drawings attached to this specification are only used to match the content disclosed in the specification, for those who are familiar with this technology to understand and read, and are not used to limit the implementation of the present invention Any modification of structure, change of proportional relationship or adjustment of size shall fall within the range covered by the technical content disclosed in the present invention without affecting the effect and purpose of the present invention. within range.

[0069] At the same time, terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in this specification are only for the convenience of description and are not used to limit this specification. The practicable scope of the invention and the change or adjustment of its relative relationship shall also be regarded as the practicable scope of the present invention without...

Embodiment 1

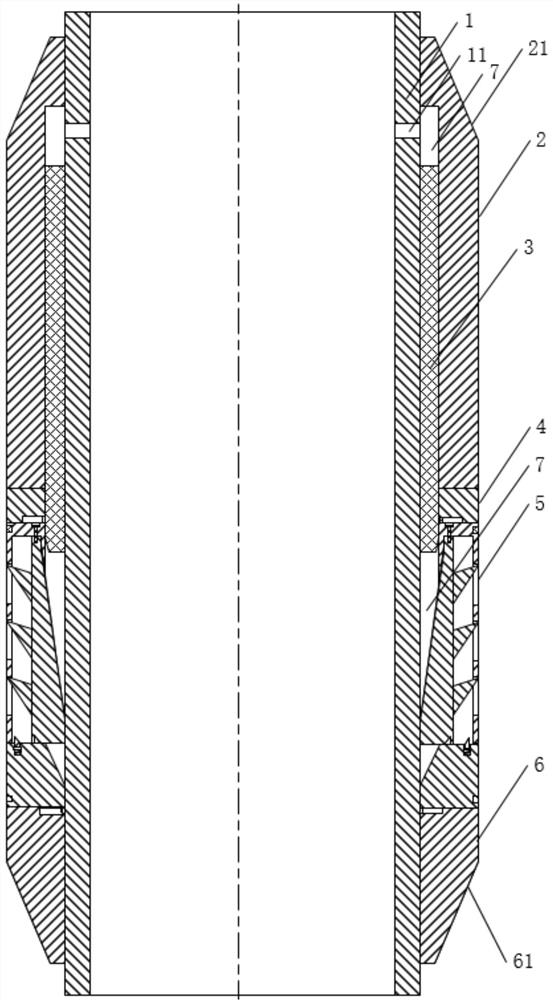

[0071] combined with Figure 1-4 , a prestressed ground anchor, including a central tube 1 and a housing 2, a piston 3, a connecting ring 4, an anchor body 5 and a first stop ring 6 that are sequentially sleeved outside the central tube 1, the housing 2. The connecting ring 4 and the anchor body 5 form an annular cavity 7 with the central tube 1, and the piston 3 is slidably arranged in the annular cavity 7; The first through hole 11 communicating with the annular cavity 7; one end of the connecting ring 4 is fixedly connected with the housing 2, and the other end is radially slidingly connected with the anchor body 5; the anchor body 5 is composed of several anchors A body unit 51 is formed. Several anchor body units 51 are arranged in a circle and combined into a hollow ring through an elastic tightening ring 52. When the piston 3 moves downward, the anchor body 5 expands radially.

[0072] The inside of the anchor unit 51 is provided with a hollow chute 5104 communicating ...

Embodiment 2

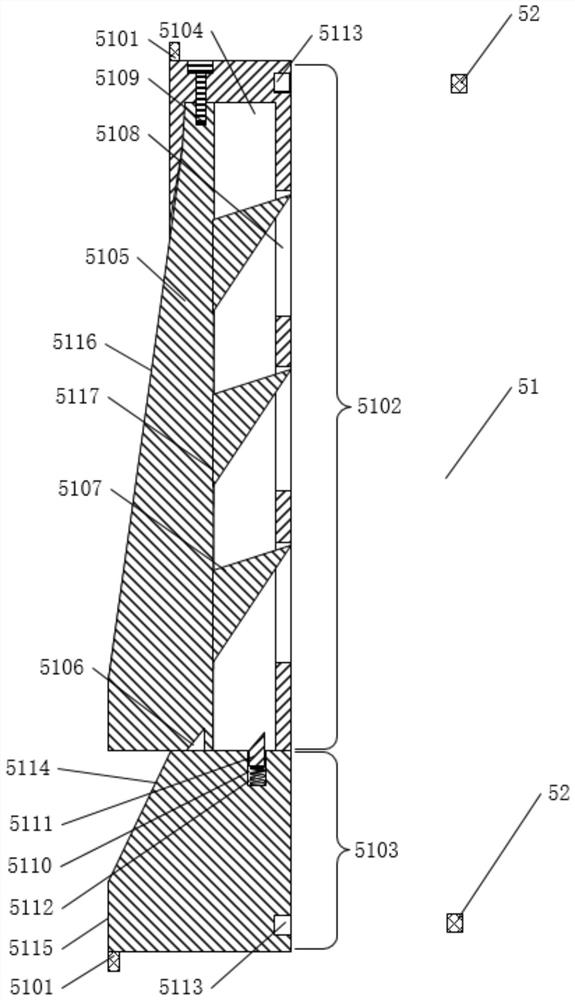

[0080] This embodiment provides another kind of prestressed ground anchor. The structure of the anchor body unit 51 in Embodiment 1 is adjusted to make it more radially expandable and more adaptable. The adjusted technical solution is as follows:

[0081] combined with Figure 5-7 , the anchor body unit 51 is provided with a hollow chute 5104 communicating with the annular cavity 7, and a radially slidable sliding plate 5105 is provided in the hollow chute 5104, and the sliding plate 5105 faces the One side of the outer wall of the anchor unit 51 is provided with an anchor fluke 5107, and the outer wall of the anchor unit 51 is provided with a second through hole 5108 through which the anchor fluke 5107 protrudes; in the initial state, the anchor fluke 5107 accommodates In the hollow chute 5104; in the anchored state, the anchor claw 5107 protrudes from the outer wall of the anchor unit 51; the outer wall of the anchor unit 51 is provided with a tightening ring groove 5113, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com