A kind of method for preparing nickel base alloy

A nickel-based alloy and alloy technology, which is applied in the field of laser cladding forming to prepare nickel-based alloys, can solve the problems of unsatisfactory requirements, powder work hardening, poor powder fluidity, etc., and achieves strong designability, high density and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

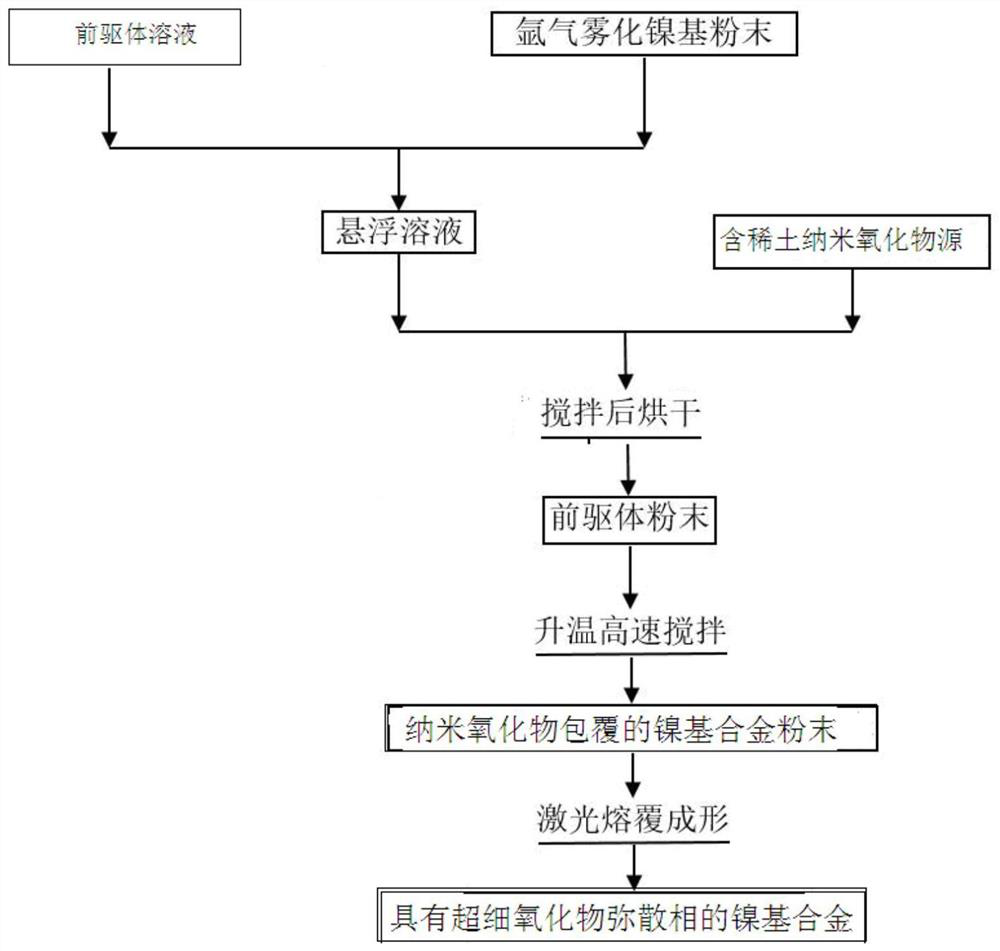

Method used

Image

Examples

Embodiment 1

[0049] Element

[0050] Ni-12wt.%Cr-6wt.%Al-1wt.%Ti-4wt.%Mo-2wt.%Nb-0.25wt.%La 2 o 3 Preparation of nickel base alloy

[0051] Argon atomized powder and nano La 2 o 3 The powder is weighed with a weight ratio of 99.75:0.25 for later use. Dissolve the weighed argon atomized powder of Ni-12wt.%Cr-6wt.%Al-1wt.%Ti-4wt.%Mo-2wt.%Nb in 5g·L -1 Polydiallyldimethylammonium chloride solution, soaked for 15 minutes, and then the nano-La 2 o 3 The powder was added into the solution and stirred for 1.5 hours, and then the solution was dried to obtain a powder precursor. Stir the powder precursor for 1 hour in an argon atmosphere at a temperature of 320° C. and a stirring propeller rotation speed of 20,000 rpm to obtain nano-oxide-coated nickel-based alloy powder. Finally, the nickel-based alloy powder is wrapped with nano-oxide for laser cladding forming. The forming parameters are powder coating thickness 0.03mm, scanning speed 1000mm / s, and scanning distance 0.05mm to obtain ODS ...

Embodiment 2

[0053] Element

[0054] Ni-18wt.%Cr-21wt.%Fe-1wt.%Co-0.6wt.%Al-1wt.%Ti-3wt.%Mo-5wt.%Nb-0.4wt.%La 2 o 3 Preparation of nickel base alloy

[0055] Will be composed as

[0056] Argon atomized powder and nano La 2 o 3 The powder is weighed with a weight ratio of 99.6:0.4 for future use. Dissolve the weighed argon atomized powder of Ni-18wt.%Cr-21wt.%Fe-1wt.%Co-0.6wt.%Al-1wt.%Ti-3wt.%Mo-5wt.%Nb in 8g·L -1 Polydiallyldimethylammonium chloride solution, soaked for 30 minutes, and then the nano-La 2 o 3 After the powder was added into the solution and stirred for 2 hours, the solution was dried to obtain a powder precursor. Stir the powder precursor for 1 hour in an argon atmosphere at a temperature of 350° C. and a stirring propeller rotation speed of 25,000 rpm to obtain nano-oxide-coated nickel-based alloy powder. Finally, the nickel-based alloy powder is wrapped with nano-oxide for laser cladding forming. The forming parameters are powder coating thickness 0.05mm, scanni...

Embodiment 3

[0058] Composition Ni-20wt.%Cr-0.3wt.%Al-0.5wt.%Ti-0.1wt.%Fe-0.6wt.%Y 2 o 3 Preparation of nickel base alloy

[0059] Argon atomized powder and nano-Y 2 o 3 The powder is weighed with a weight ratio of 99.4:0.6 for future use. Dissolve the weighed Ni-20wt.%Cr-0.3wt.%Al-0.5wt.%Ti-0.1wt.%Fe argon atomized powder in 4g·L -1 cysteine solution, soaked for 10 minutes, and then the nano-Y 2 o 3 After the powder was added into the solution and stirred for 2 hours, the solution was dried to obtain a powder precursor. Stir the powder precursor for 1 hour in an argon atmosphere at a temperature of 500° C. and a stirring propeller rotating at 20,000 rpm to obtain nano-oxide-coated nickel-based alloy powder. Finally, the nickel-based alloy powder is wrapped with nano-oxide for laser cladding forming. The forming parameters are powder coating thickness 0.03mm, scanning speed 2500mm / s, and scanning distance 0.03mm to obtain ODS nickel-based alloy products with the target shape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com