A high-efficiency organic piston ring carbon removal and repair agent

A technology of piston ring and repairing agent, applied in the field of organic piston ring decarbonization repairing agent, can solve the problems of unfavorable combustion chamber and piston ring protection, difficult combustion of residual liquid in combustion chamber, and little effect of carbon deposition, etc., so as to improve solubility. and dissolution stability, improving corrosion resistance, preventing stuttering and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

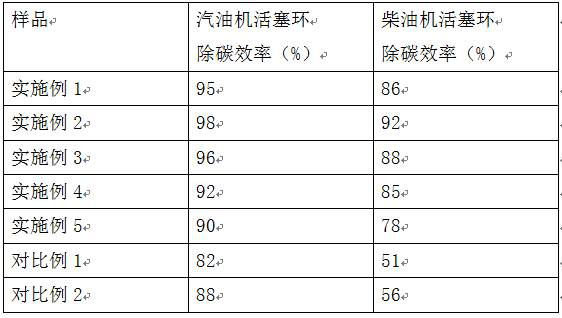

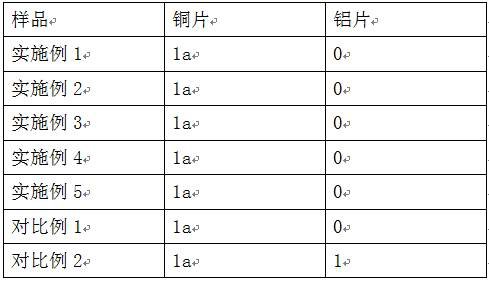

Examples

Embodiment 1

[0037] An organic piston ring carbon removal repair agent. In parts by mass, the following components are included: 80 parts of carbon deposit dissolving agent, 5 parts of detergent and dispersant, 5 parts of ester type lubricating thickener, 1 part of solvent type surfactant, 1 part of oil stain disintegration accelerator, auxiliary agent 1 serving.

[0038] The carbon deposit dissolving agent is an amide compound, and the amide compound is N,N-dimethylformamide.

[0039] The detergent and dispersant is a polymer ether amine, and the polymer ether amine is SURFONAMINE FL1000.

[0040] The ester type lubricating tackifier is CRODA Perfad 3336.

[0041] The solvent-based surfactant is N,N dimethyl 9-decenamide.

[0042] The oil stain disintegration accelerator is diphenyl-2-pyridylphosphine.

[0043] The preparation technology of described organic piston ring carbon removal repairing agent is:

[0044] (1) Melt m-tolyldiethanolamine whose mass is 1 / 3 of the oil stain disin...

Embodiment 2

[0049]An organic piston ring carbon removal and repairing agent, comprising the following components in parts by mass: 65 parts of carbon deposit dissolving agent, 10 parts of cleaning and dispersing agent, 3 parts of ester type lubricating tackifier, 5 parts of solvent type surfactant, 1.5 parts of oil stain disintegration accelerator and 0.5 parts of auxiliary agent.

[0050] The carbon deposit dissolving agent is an amide compound, and the amide compound is N,N dimethyldecylamide.

[0051] The detergent and dispersant is a polymer ether amine, and the polymer ether amine is SURFONAMINE B100.

[0052] The ester type lubricating tackifier is PE3100.

[0053] The solvent-based surfactant is N,N dimethyl 9-decenamide.

[0054] The oil stain disintegration accelerator is a mixture of triphenylphosphine:diphenyl-2-pyridylphosphine with a mass ratio of 1:1.

[0055] The preparation technology of described organic piston ring carbon removal repairing agent is:

[0056] (1) Melt...

Embodiment 3

[0061] An organic piston ring carbon removal and repairing agent, comprising the following components in parts by mass: 50 parts of carbon deposit dissolving agent, 20 parts of cleaning and dispersing agent, 1 part of ester type lubricating tackifier, 10 parts of solvent type surfactant, 2 parts of oil stain disintegration accelerator and 0.1 part of auxiliary agent.

[0062] The carbon deposit dissolving agent is an amide compound, and the amide compound is 1-cyclohexyl-2-pyrrolidone.

[0063] The detergent and dispersant is a polymer ether amine, and the polymer ether amine is Yate Chemical T3595.

[0064] The ester type lubricant tackifier is Ketjenlube 3700.

[0065] The solvent-based surfactant is STEPOSOL MET-10U.

[0066] The oil stain disintegration accelerator is triphenylphosphine.

[0067] The preparation technology of described organic piston ring carbon removal repairing agent is:

[0068] (1) Melt m-tolyldiethanolamine whose mass is 1 / 2 of the oil stain disin...

PUM

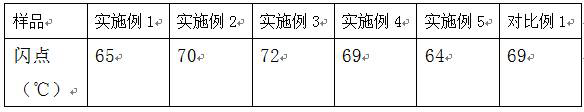

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com