Simulated Mars soil concrete suitable for extrusion and preparation method thereof

A concrete and fire soil technology, applied in the fields of aviation, aerospace and architectural coatings, can solve the problems of fire soil uncertainty and complex fire soil gradation, and achieve the effect of easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A method for preparing fire soil "concrete" suitable for extrusion. First, pour 100 parts of simulated fire soil and 45-46 parts of calcium silicate into a container, add 20-21 parts of water, and turn on the stirring device to process the materials. Physically mix, at the same time pour 0.4-0.5 parts of hydroxypropyl methylcellulose into the remaining water, and stir evenly with a glass rod, then gradually add the hydroxypropyl methylcellulose solution into the simulated fire soil "concrete" and continue stirring until a "concrete" slurry suitable for extrusion molding with a viscosity of 50-100 Pa·s and good fluidity is prepared.

[0034] Extrude the pretreated "concrete" slurry from the printing nozzle, and control the extrusion flow to 100-150mm 3 / min, in order to realize the continuous and controllable extrusion molding of simulated fire soil concrete.

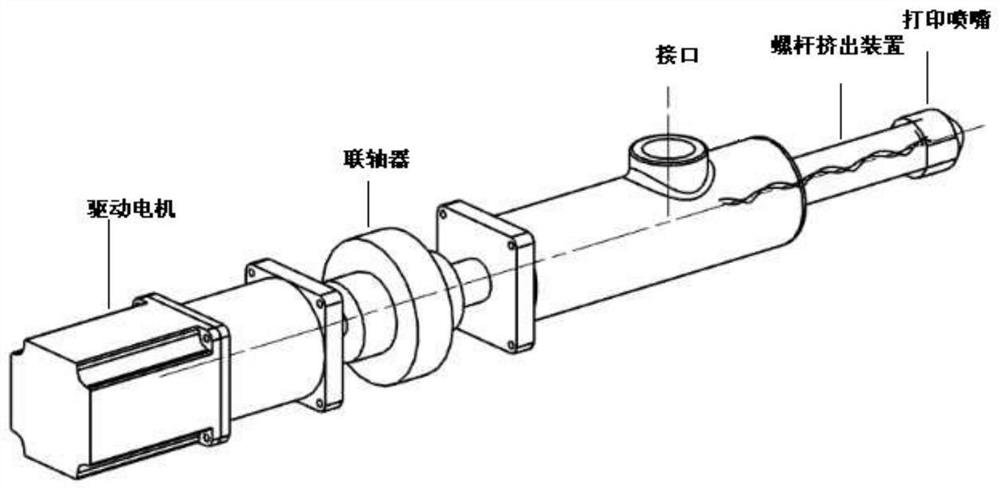

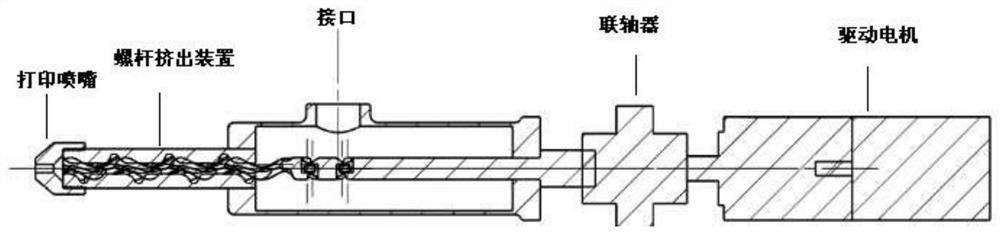

[0035] The extrusion device used in the method includes a drive motor, a coupling, a screw extrusion device an...

Embodiment

[0040] By setting the feed port on the screw extrusion device, the discharge end of the high-pressure pipe can be connected to realize the printing of large structural parts with a maximum stroke of 2m*2m*1m, and the screw extrusion device can be connected to a certain size of 3D printing The funnel realizes the instant filling of small batches of simulated fire soil mixture, prevents the screw extrusion device and printing nozzle from being blocked or even scrapped due to the short-term solidification of a large amount of slurry, and it is easier to realize the control of process parameters.

[0041] Step 1: Use modeling software to design and slice the nozzle structure. The slicing is to perform hierarchical processing on the design structure.

[0042] Step 2: Select a 3D printing material (such as nylon) with a printing accuracy of 0.1mm as the material of the printing nozzle to ensure the controllable extrusion of the simulated fire soil "concrete" slurry.

[0043] Step 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com