Anti-blue-ray and high-transmittance coated front plate and anti-blue-ray solar cell module

A solar cell, high transmittance technology, applied in the fields of photovoltaic power generation, electrical components, circuits, etc., can solve the problems affecting the power generation efficiency of solar cell modules, heavy sunlight absorption of dyed film, poor transmission, etc., to achieve thin film deposition efficiency High, excellent optical constant, the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

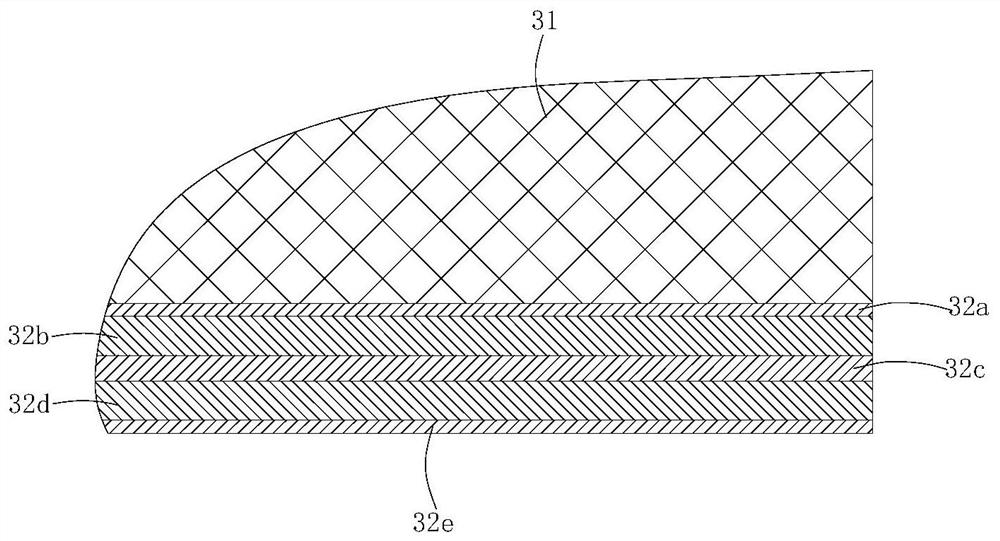

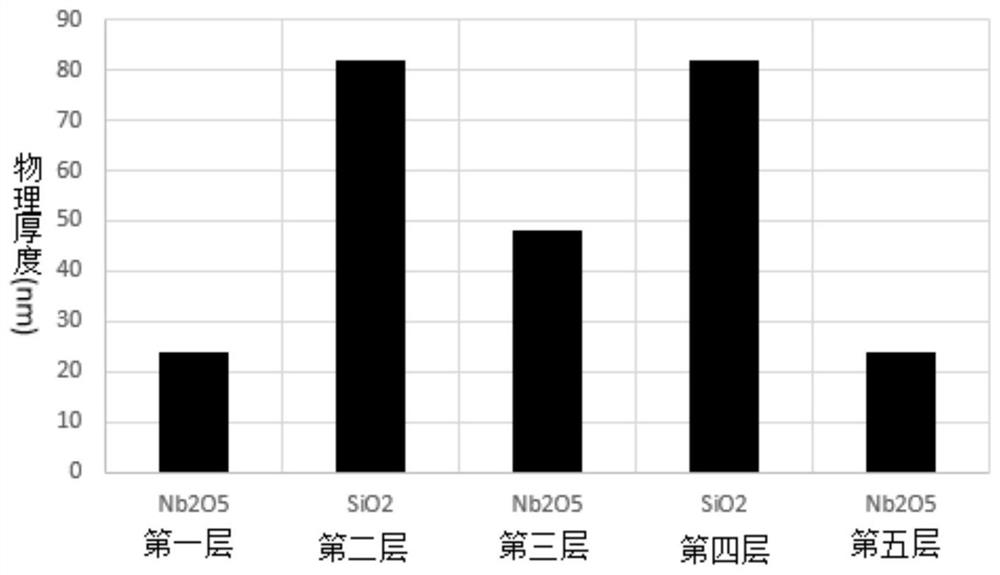

[0064] Such as figure 1 As shown, the anti-blue light, high-transmittance coating front plate 3 includes float glass, and the first film structure is provided on the float glass, and the first film structure includes three high-refractive index film layers and two low-refractive film layers. rate film layer, the coating material used in the high refractive index film layer is Nb 2 o 5 , the coating material used for the low refractive index film layer is SiO 2 , three layers of high-refractive-index coatings and two layers of low-refractive-index coatings are distributed sequentially at intervals, and the coatings closest to and farthest from the surface of the float glass are high-refractive-index coatings.

[0065] The first film structure includes three high-refractive-index film layers and two low-refractive-index film layers. From the surface of the float glass to the outside, there are the first high-refractive-index film layer 32a and the second low-refractive-index f...

Embodiment 2

[0104] The anti-blue light, high transmittance coating front plate 3 includes float glass, and the first film structure is arranged on the float glass, and the first film structure includes three layers of high refractive index film layers and two layers of low refractive index film layers , the coating material used in the high refractive index film layer is Nb 2 o 5 , the coating material used for the low refractive index film layer is SiO 2 , three layers of high-refractive-index coatings and two layers of low-refractive-index coatings are distributed sequentially at intervals, and the coatings closest to and farthest from the surface of the float glass are high-refractive-index coatings.

[0105] The first film structure includes three high-refractive-index film layers and two low-refractive-index film layers. From the surface of the float glass to the outside, there are the first high-refractive-index film layer 32a and the second low-refractive-index film layer 32b. , ...

Embodiment 3

[0141] The anti-blue light, high transmittance coating front plate 3 includes float glass, and the first film structure is arranged on the float glass, and the first film structure includes three layers of high refractive index film layers and two layers of low refractive index film layers , the coating material used in the high refractive index film layer is Nb 2 o 5 , the coating material used for the low refractive index film layer is SiO 2 , three layers of high-refractive-index coatings and two layers of low-refractive-index coatings are distributed sequentially at intervals, and the coatings closest to and farthest from the surface of the float glass are high-refractive-index coatings.

[0142] The first film structure includes three high-refractive-index film layers and two low-refractive-index film layers. From the surface of the float glass to the outside, there are the first high-refractive-index film layer 32a and the second low-refractive-index film layer 32b. , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com