Trailing arm suspension of hub motor

A hub motor and trailing arm technology, which is applied in the field of vehicle engineering, can solve problems such as insufficient integration of cables and water pipes, insufficient longitudinal flexibility of the suspension, and insufficient carrying capacity, so as to reduce the maintenance support capability requirements and improve the ability to pass through geometric obstacles , the effect of increased longitudinal flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

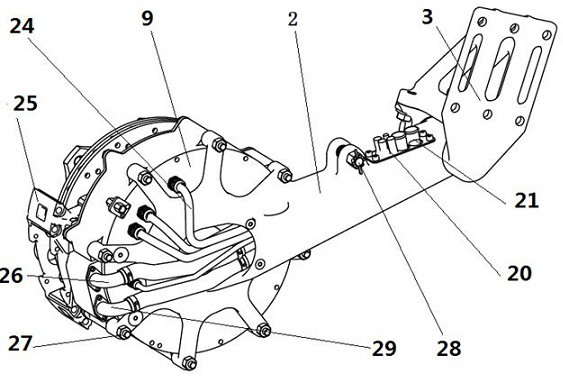

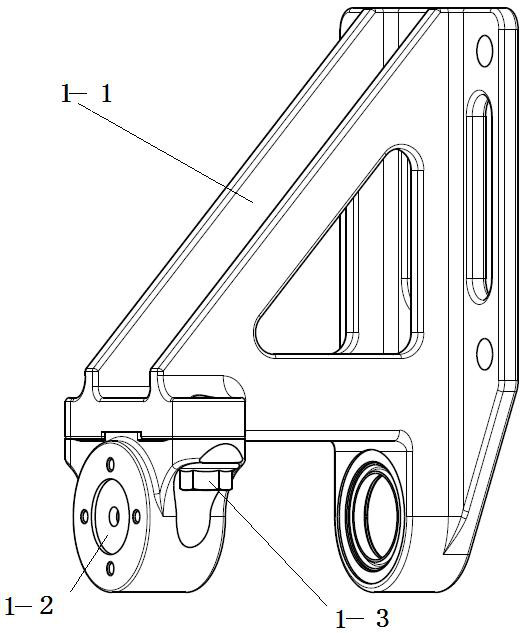

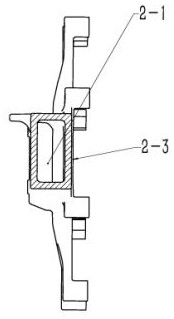

[0045] figure 1 , 2 A schematic diagram of a single trailing arm hub motor drive module (single trailing arm axle) is shown. Such as figure 1 and 2 As shown, the present invention provides a single trailing arm hub motor drive module, including trailing arm mounting bracket 3, trailing arm 2, hub motor 8, cable 24, brake 25, cooling water pipes 26 and 29, fastening screw 27 and oil and gas Connecting pin 28 of spring 4. The mounting bracket 3 of the trailing arm has a threaded interface, which is convenient to be fixed to the vehicle body by bolts; the trailing arm 2 is of a thin-walled structure, preferably with a thin wall thickness of 5 mm, and its pin end is coupled with the mounting bracket 3 to form a rotating pair, realizing the winding of the trailing arm. The vehicle body swings, and the cross section of the trailing arm 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com