Prefabricated-column-storing and overturn-preventing construction device and method

A kind of technology of construction device and construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

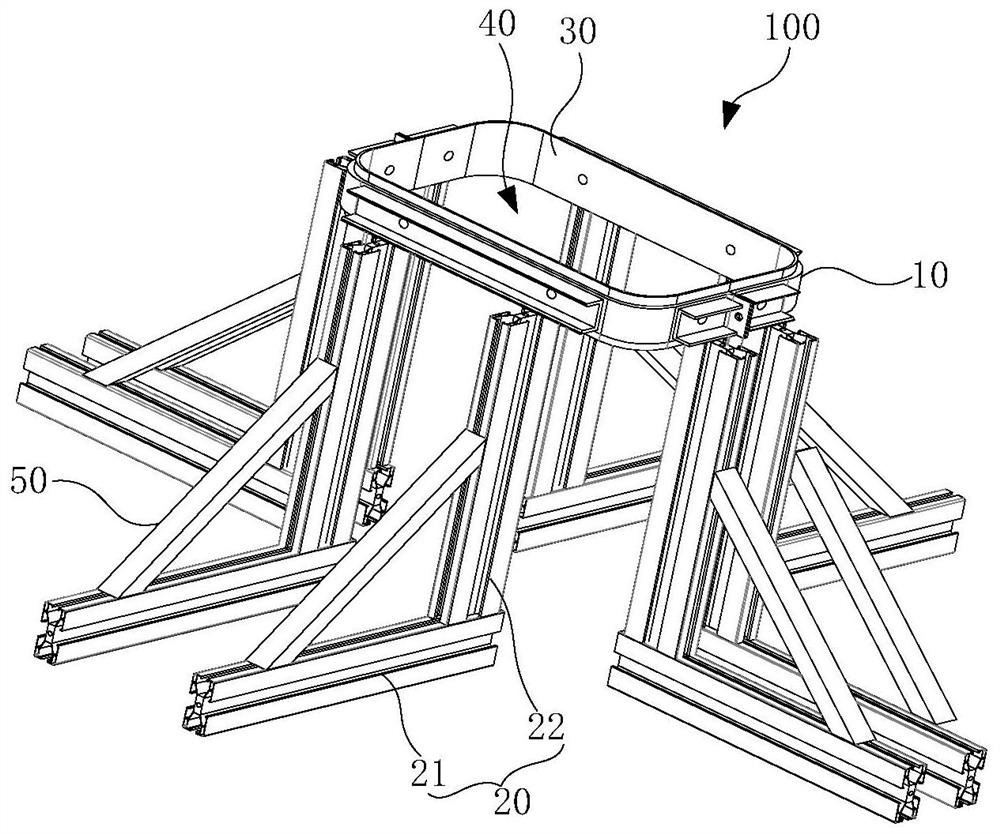

[0028] see figure 1 , which is a structural schematic diagram of a prefabricated column storage anti-overturning construction device provided in the first embodiment of the present invention. At least one cushion 30 and a plurality of supports 20. Wherein, each protection part 10 has a housing chamber 40, and the housing chamber 40 can circumferentially accommodate the prefabricated column to be maintained; the cushion layer 30 is located in the housing chamber 40, and is connected to the protection part 10; each support member 20 is connected to the protection part 10 and the prefabricated Column maintenance position.

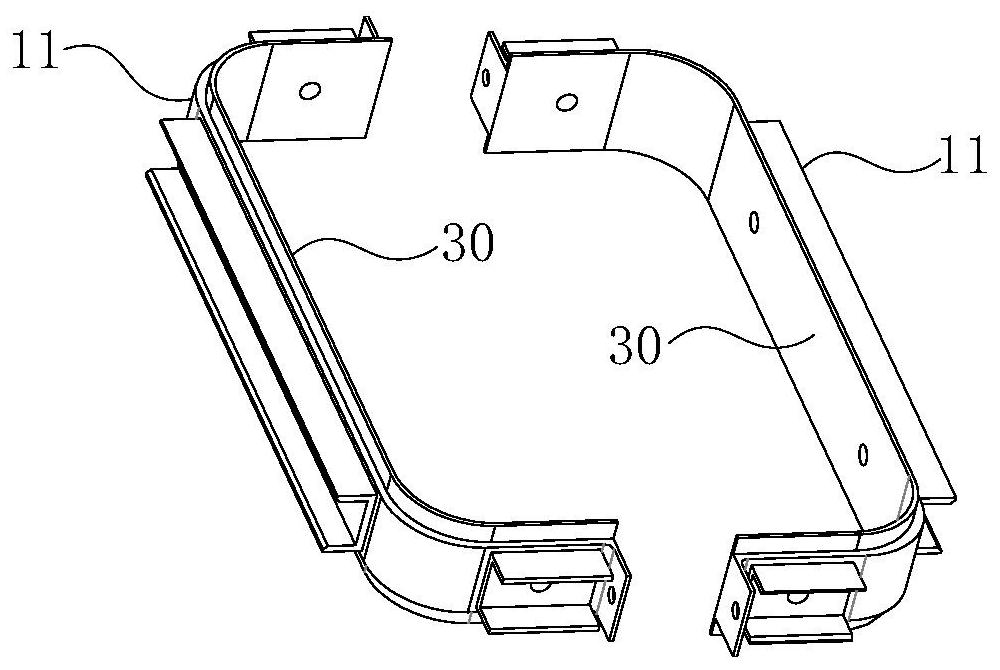

[0029] Specifically, see figure 2 , the protective part 10 includes two protective pieces 11, for example, the two protective pieces 11 encircle and form a square accommodation cavity 40, and the two protective pieces 11 are connected by bolts, of course, they can also be connected by other methods such as buckles; preferably, the two The two guards 11 can...

no. 2 example

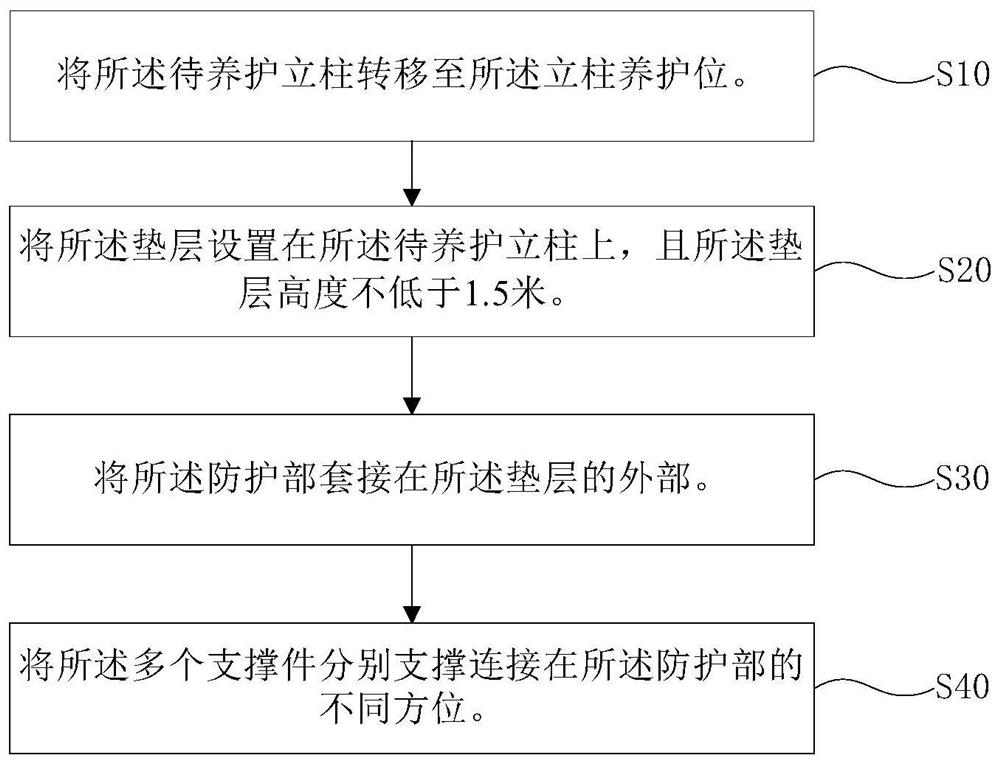

[0038] see figure 2 , which is a prefabricated column storage anti-overturning construction method provided in the second embodiment of the present invention. The prefabricated column storage anti-overturning construction method is used to install the prefabricated column storage anti-overturning construction device as described in the first embodiment. on the prefabricated column to be maintained. The construction method for storing the anti-overturning of the prefabricated column includes, for example:

[0039] Step S10, transferring the prefabricated column to be maintained to the prefabricated column maintenance platform;

[0040] Step S20, setting the cushion layer on the prefabricated column to be prefabricated and maintained, and the height of the cushion layer is not less than 1.5 meters;

[0041] Step S30, sleeve the protective part on the outside of the cushion;

[0042] Step S40, respectively support and connect the plurality of support members at different posi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com