Turning tool structure of steel bar friction welding machine

A technology of friction welding and turning tools, which is applied in the direction of tools used in lathes, turning equipment, tool holder accessories, etc., can solve problems that affect the normal operation of steel bar welding, affect the quality of steel bar processing, and troublesome tool replacement, etc., to achieve Guarantee the economic benefits of the work, ensure the efficiency of production work, and facilitate the maintenance and replacement of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions in the embodiments of the present invention will be described clearly and completely below. The embodiments of the present invention, and all other embodiments obtained by those of ordinary skill in the art without creative work, fall within the protection scope of the present invention.

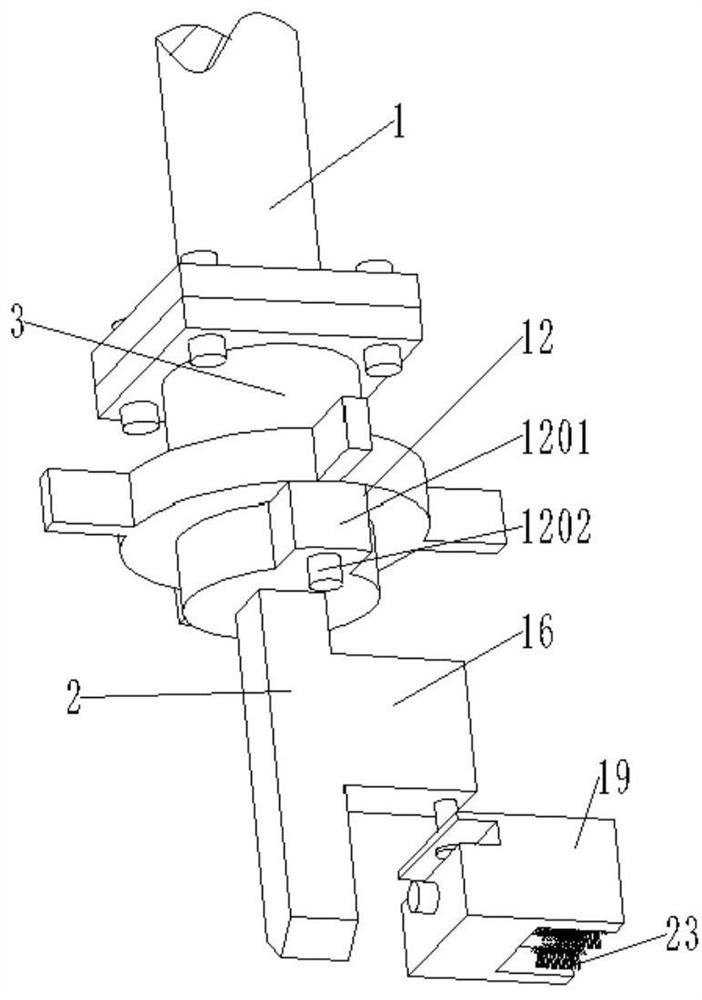

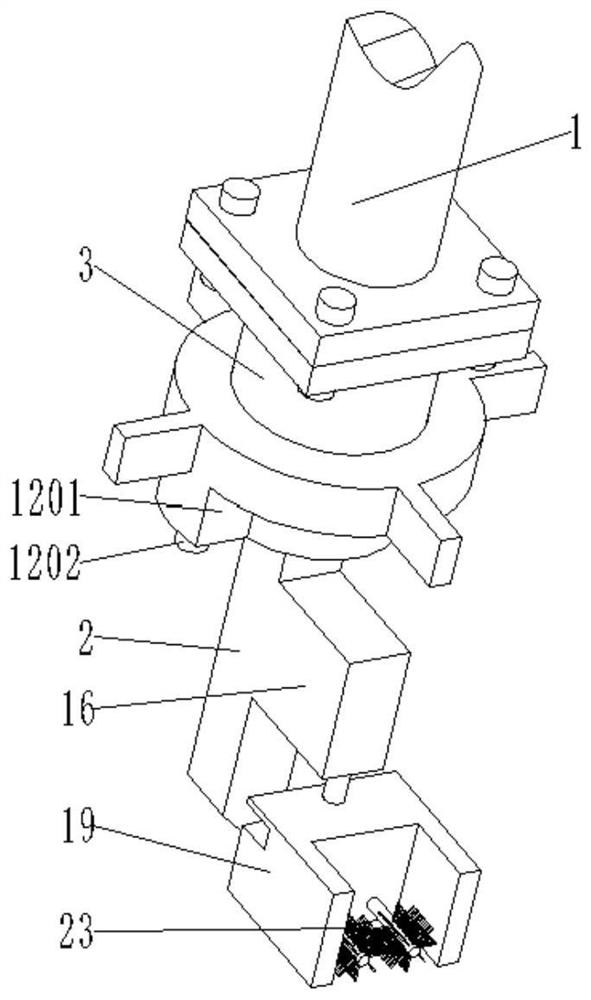

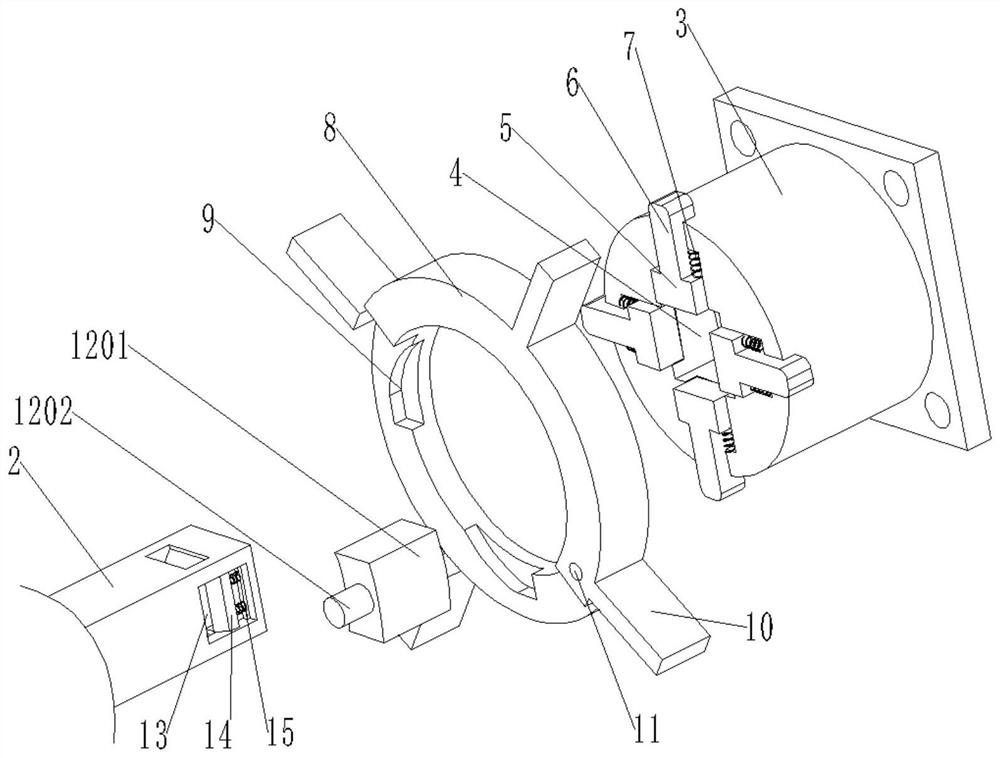

[0029] Please refer to the picture Figure 1 to Figure 7 , The present invention provides a technical solution: a turning tool structure of a steel friction welding machine, comprising a telescopic rod 1, a turning tool body 2, a connecting column 3 and a locking mechanism 12, a transmission gear set 21, and a cleaning brush 23;

[0030] One end of the telescopic rod 1 is welded with a first connecting plate, one end of the connecting column 3 is welded with a second connecting plate, and the first connecting plate and the second connecting plate are fixedly connected by bolts, and the other end of the connecting column 3 is fixed with Slot 4;

[0031] The connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com