A device and method for ruminant food waste treatment

A kitchen waste and processing device technology, which is applied in separation methods, chemical instruments and methods, transportation and packaging, etc., can solve the problems of waste, failure, and the contradiction between processing time and processing volume of kitchen waste, and achieve solid-liquid separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

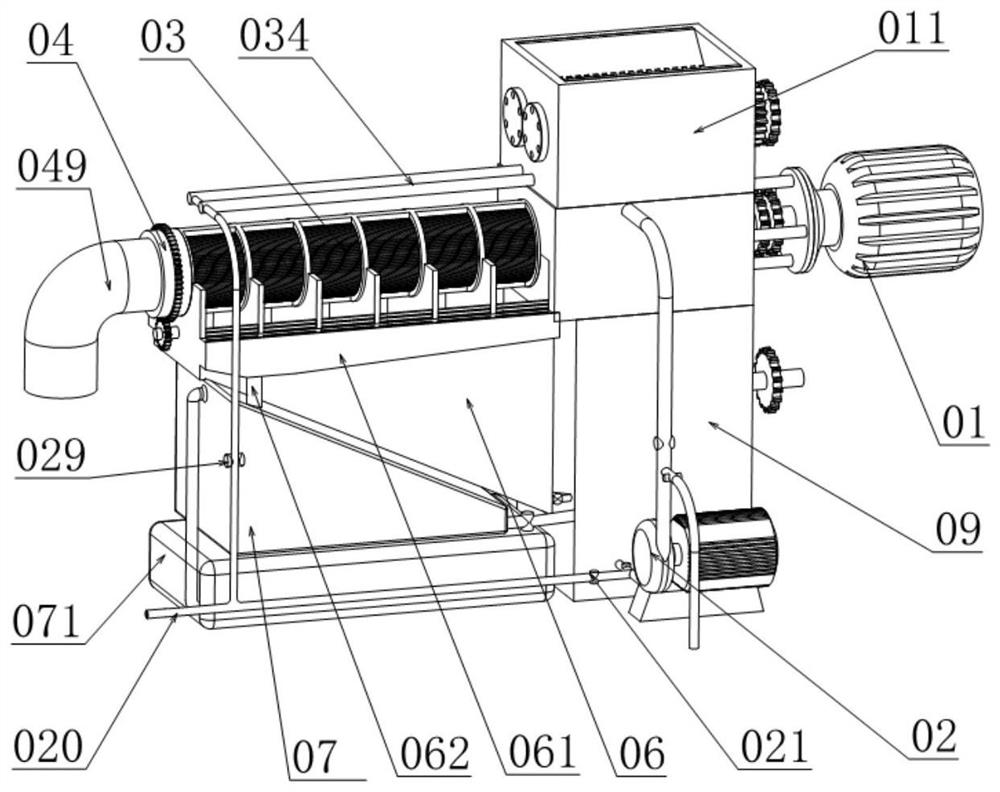

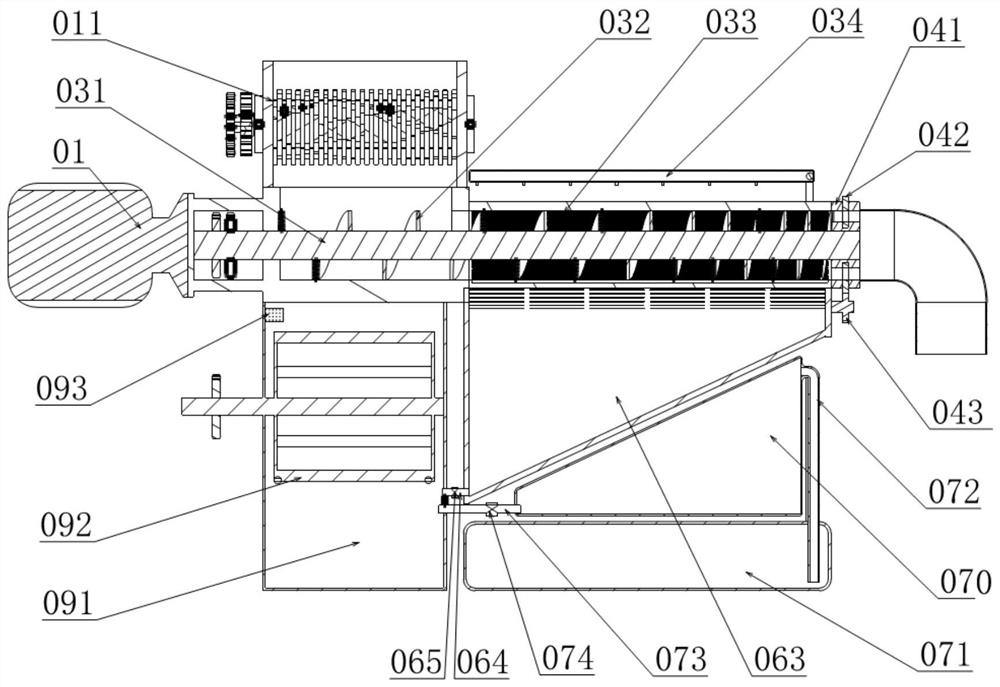

[0025] like figure 1 and figure 2 As shown in the figure, the present invention is a ruminant-type kitchen waste treatment device, and the technical scheme adopted is as follows: including a circulation system 02, a screw pressing mechanism 03, a convergence and solids removal mechanism 04, a slurry separation mechanism 06, an oil-water sedimentation mechanism 07, and a digestion mechanism 09; The rear part of the screw pressing mechanism 03 is connected with the converging and solid removing mechanism 04, the lower part of the screw pressing mechanism 03 is connected with the slurry separation mechanism 06, and the slurry separation mechanism 06 is connected with the oil-water The sedimentation mechanism 07 is connected, the slurry separation mechanism 06 and the oil-water sedimentation mechanism 07 are both connected with the digestion mechanism 09, and the circulation system 02 is respectively connected with the screw press mechanism 03 and the digestion mechanism 09, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com