Preparation method of triazine-based porous organic nanoparticle-assembled membrane

A nanoparticle assembly and nanoparticle technology, which is applied in the field of membrane separation, can solve the problems of poor interlayer force, poor solvent dispersibility, and separation layer thickness, and achieve the effects of good stability, simple preparation method and high permeability selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

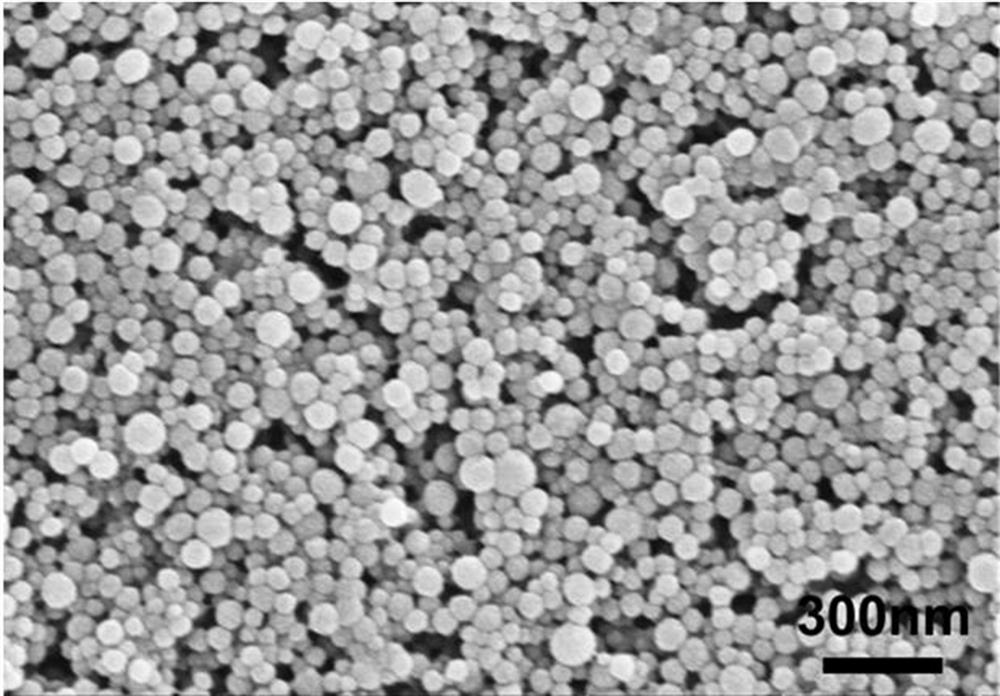

Image

Examples

preparation example Construction

[0021] The method for preparing a membrane based on triazine porous organic nanoparticles assembly described in this embodiment comprises the following steps:

[0022] 1) Add 0.05 to 1.0 parts by mass of triazine derivatives to 25 to 500 parts by mass of acetic acid aqueous solution, stir thoroughly to dissolve it; then add 0.2 to 1.2 parts by mass of 1,2-dicarbonyl The compound and 0.05-0.6 parts by mass of aldehyde compounds are reacted at 60-120° C. for 12-72 hours to obtain a triazine-based porous organic nanoparticle dispersion;

[0023] 2) Add 0.01-1.0 parts by mass of the above-mentioned triazine-based porous organic nanoparticle dispersion and 0.005-0.05 parts by mass of cationic polyelectrolyte to 200-600 parts by mass of water to prepare a mixed and diluted dispersion, and after ultrasonic treatment, Perform pressure filtration on the surface of the porous support membrane to form a membrane; then immerse the above-mentioned assembled membrane in the aqueous solution...

Embodiment 1

[0027] Add 0.05 g of 2,4,6-tris(4-aminophenyl)-1,3,5-triazine into 25 g of 10% acetic acid aqueous solution, and stir magnetically at 500 rpm for 1 hour to dissolve; Then add 0.2g aceguvaldehyde and 0.05g formaldehyde to the above solution, and react at 60°C for 72 hours to obtain a dispersion of triazine porous organic nanoparticles; 0.01g of the above dispersion of triazine porous organic nanoparticles and 0.005g Polysaccharides were added to 200g water to prepare a mixed and diluted dispersion. After ultrasonication at 28KHZ for 15 minutes, the above mixed and diluted dispersion was filtered on the surface of a polysulfone ultrafiltration membrane under an operating pressure of 0.05MPa; Dialdehyde aqueous solution, cross-linking reaction at 15° C. for 2 hours, take out and remove the residual aqueous solution on the surface of the membrane, wash with deionized water, and obtain a triazine-based porous organic nanoparticle assembly membrane.

[0028] Triazine porous organic ...

Embodiment 2

[0030] Add 1 g of 2,4,6-tris(4-aminophenyl)-1,3,5-triazine into 500 g of 50% acetic acid aqueous solution, stir magnetically at 1500 rpm for 3 hours to dissolve it; then Add 1.2g aceglyoxal and 0.6g formaldehyde in above-mentioned solution, react at 120 ℃ for 12 hours, obtain triazine class porous organic nano particle dispersion liquid; 1g above-mentioned triazine class porous organic nano particle dispersion liquid and 0.05g chitosan Add it to 600g of water to prepare a mixed and diluted dispersion. After ultrasonication at 40KHZ for 5 minutes, filter the above mixed and diluted dispersion on the surface of a polysulfone ultrafiltration membrane under an operating pressure of 0.20 MPa; then immerse the obtained membrane in 2% glutaraldehyde In the aqueous solution, the cross-linking reaction was carried out at 35°C for 0.5 hours, the residual aqueous solution on the surface of the membrane was taken out and removed, and after washing with deionized water, the assembled membra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com