Propeller model construction method based on ship test

A construction method and propeller technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of cumbersome modification and long time for propeller modeling, avoiding the cumbersome manual operation and avoiding cumbersomeness. , the effect of simple and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

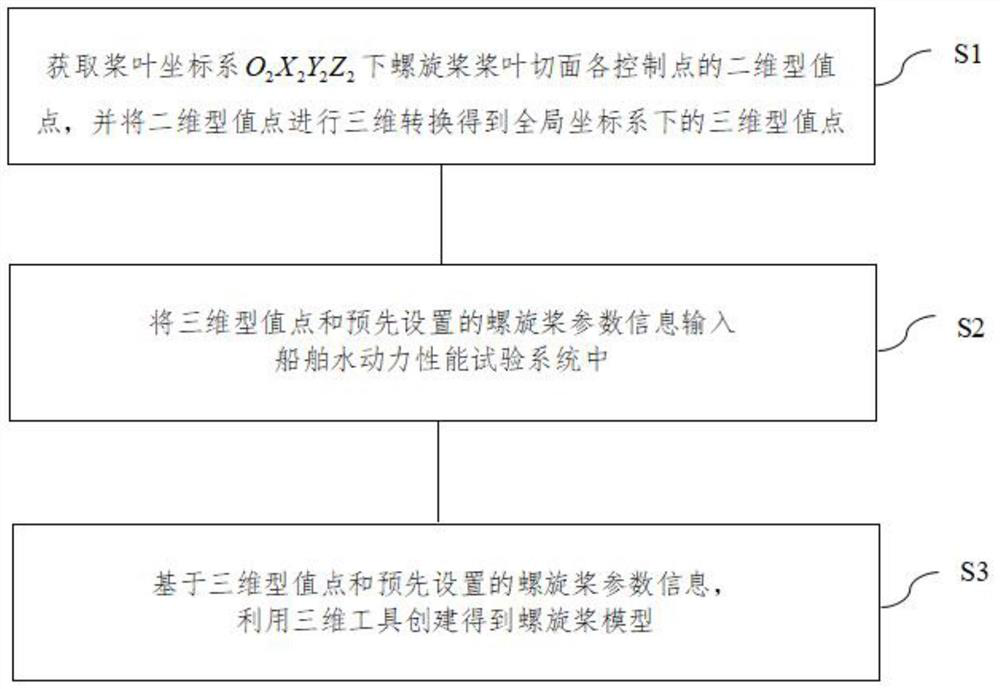

[0051] Such as figure 1 As shown, the flow chart of the propeller model construction method based on the ship test provided in this embodiment, in this embodiment, constructing the propeller model in the ship hydrodynamic simulation test system includes the following steps:

[0052] S1. Obtain each control point of the propeller blade section in the blade coordinate system O 2 x 2 Y 2 Z 2 The two-dimensional value points below, and the three-dimensional conversion of the two-dimensional value points to obtain the three-dimensional value points in the global coordinate system.

[0053] Step S1 specifically includes:

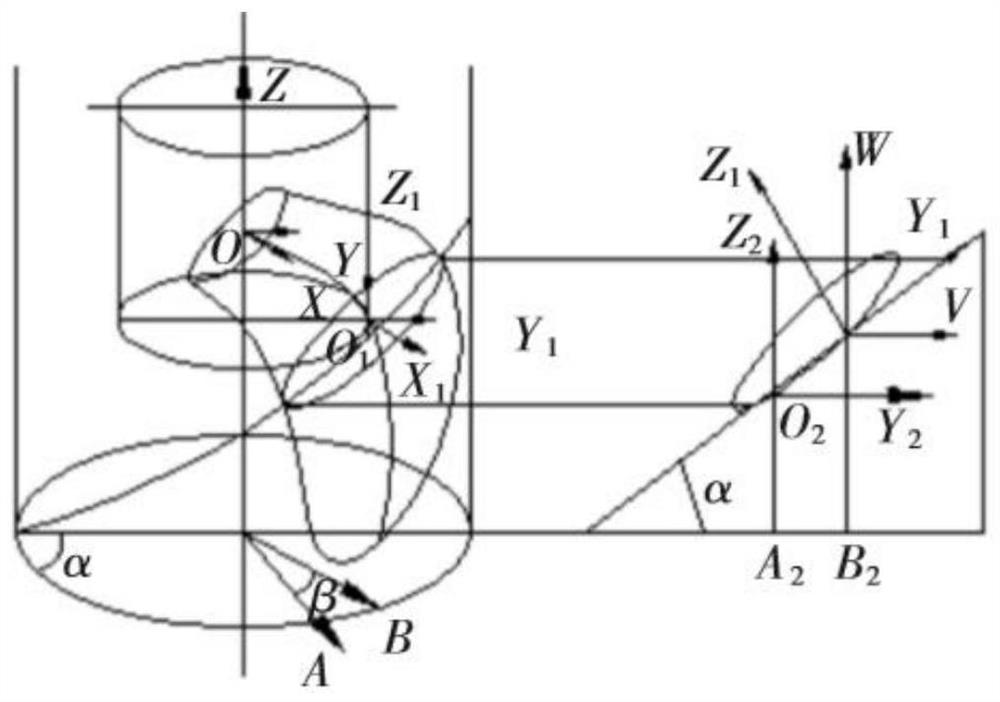

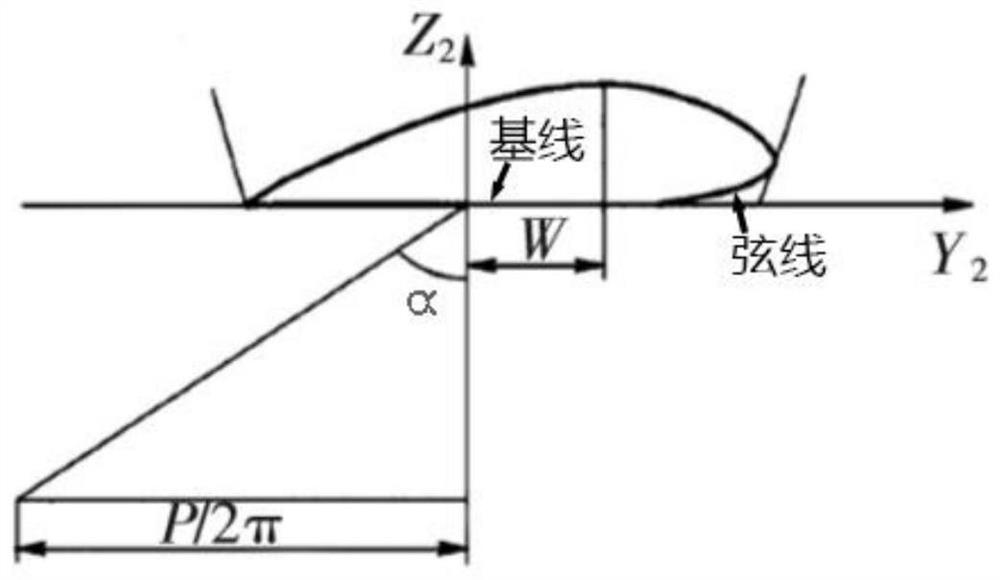

[0054] S11. Obtain each control point of the propeller blade section in the blade coordinate system O 2 x 2 Y 2 Z 2 The two-dimensional value point under (Y 2 ,Z 2 ), the two-dimensional value points of each control point on the propeller blade section (Y 2 ,Z 2 ) is an approximation obtained through complex projection of the helical surface intersecte...

Embodiment 2

[0084] Based on the propeller model construction method proposed in Embodiment 1, this embodiment provides a propeller test model generation and application process, including the following steps:

[0085] A1. According to the test requirements, determine the type of propeller, based on the ship hydrodynamic simulation test system, convert the two-dimensional value points of each control point of the propeller blade section, and save it as a txt format file;

[0086] A2. Select the txt format file to be imported, and generate three-dimensional discrete data points on the model creation interface of the ship hydrodynamic simulation test system, and the corresponding lines and surfaces are also drawn successfully at the same time, and the error accuracy is controlled within one thousandth;

[0087] A3. Save the drawn propeller model in the database model library for calling by the ship hydrodynamic simulation test system;

[0088] A4. Input the basic parameters of the propeller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com