Corrosion-resistant lifting oil cylinder

A lifting oil cylinder, corrosion-resistant technology, applied in the direction of cylinder, engine seal, fluid pressure actuating device, etc., can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

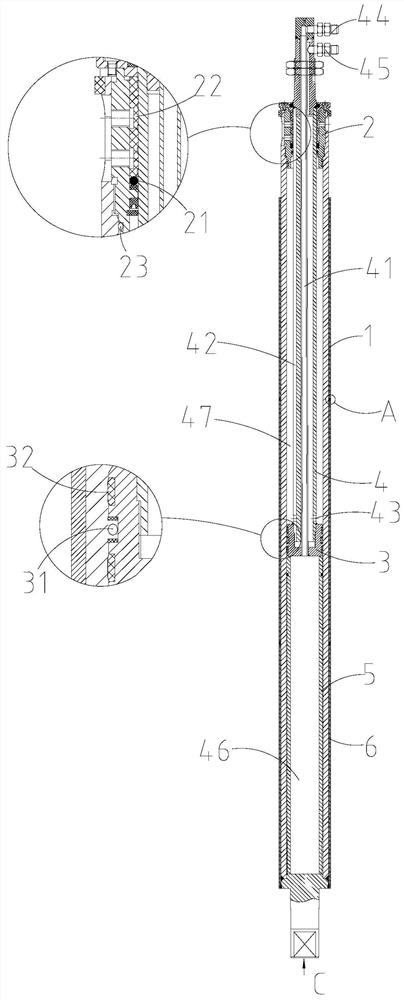

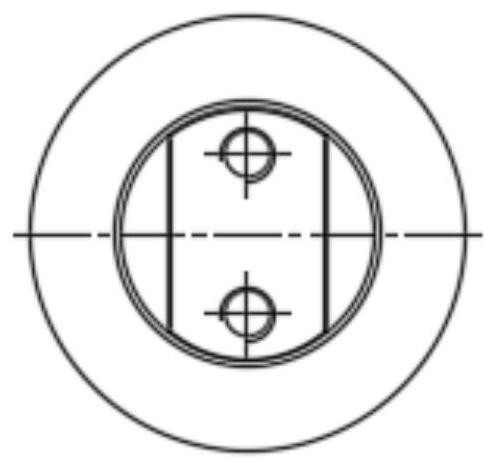

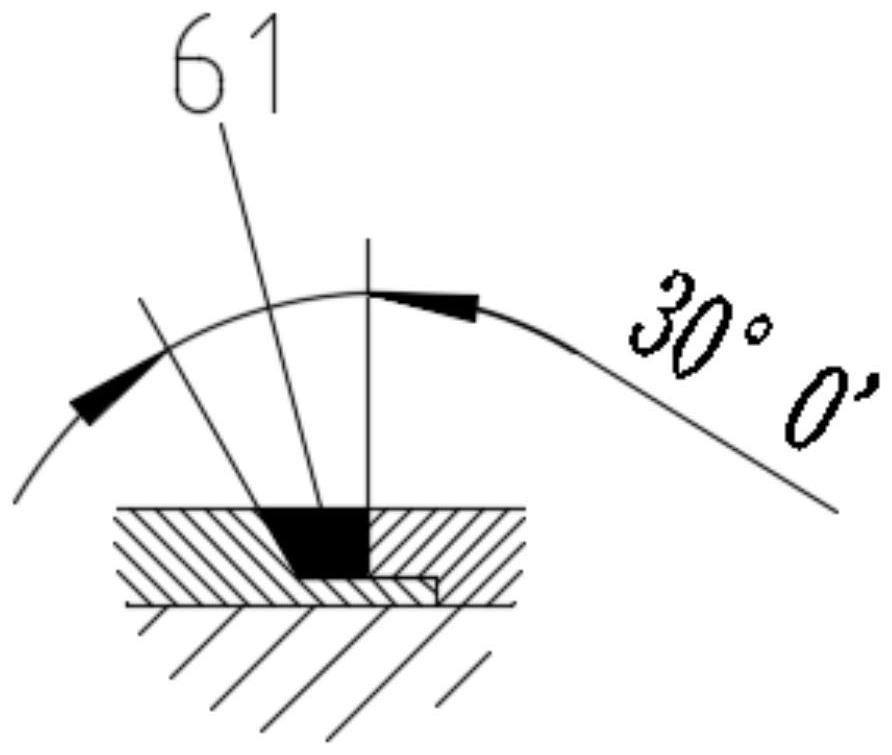

[0018] See attached figure 1 , figure 2 As shown, a corrosion-resistant lifting cylinder in this embodiment includes a cylinder 1, the upper end of the cylinder 1 is connected to a gland 2, and the gland 2 and the cylinder 1 are locked by bolts. The cylinder 1 is provided with a piston 3 and a plunger rod 4 , the lower end of the plunger rod 4 is connected to the piston 3 , and the upper end of the plunger rod 4 is inserted on the gland 2 . In order to reduce the cost of the oil cylinder, the cylinder barrel 1 includes a thin-walled tube, and the outer surface of the thin-walled tube is covered with an outer sleeve made of 304 material (304 stainless steel). The above-mentioned thin-walled tube is coated with 304 material (304 stainless steel), which does not reduce the corrosion resistance effect and strength. combine image 3 As mentioned above, the outer casing 6 is realized by welding the three-section casing and then processing, such as using: C276 / C22 pipe material. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com