Preparation method of periodic multi-directional thickness gradient thin films

A multi-directional and periodic technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems that multi-directional thickness gradients cannot be realized, and achieve easy control of process conditions, simple operation, and wide The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

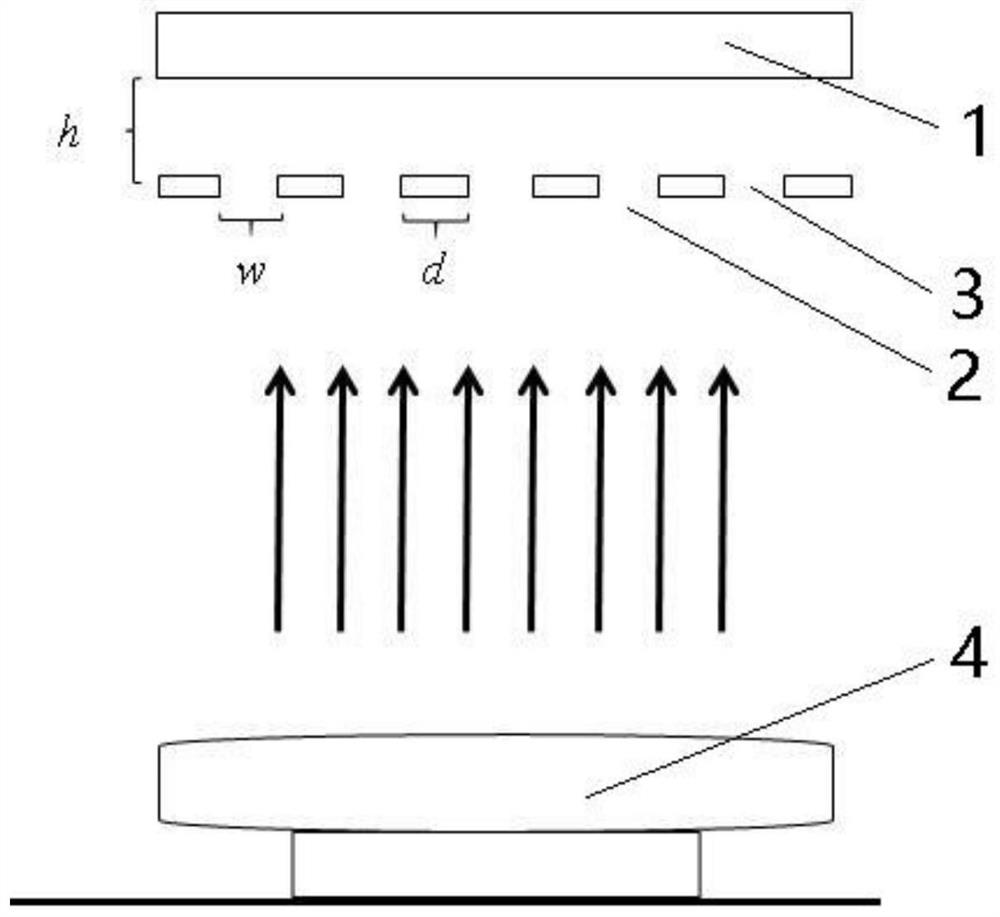

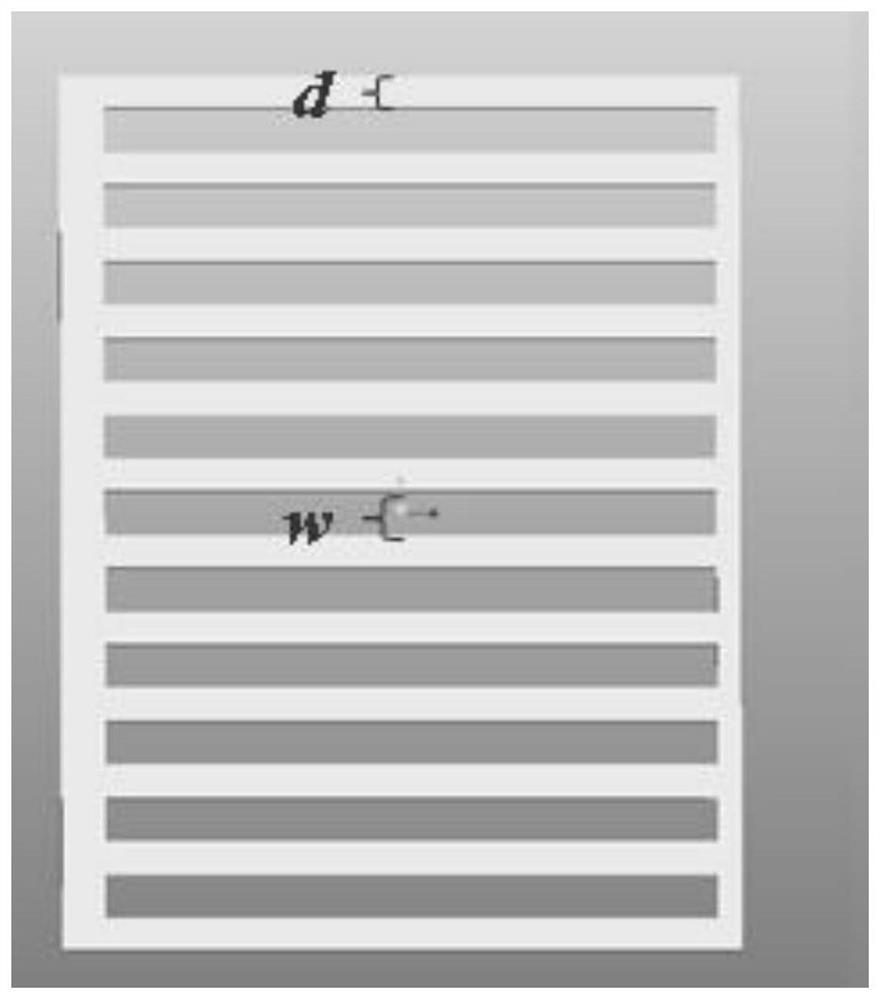

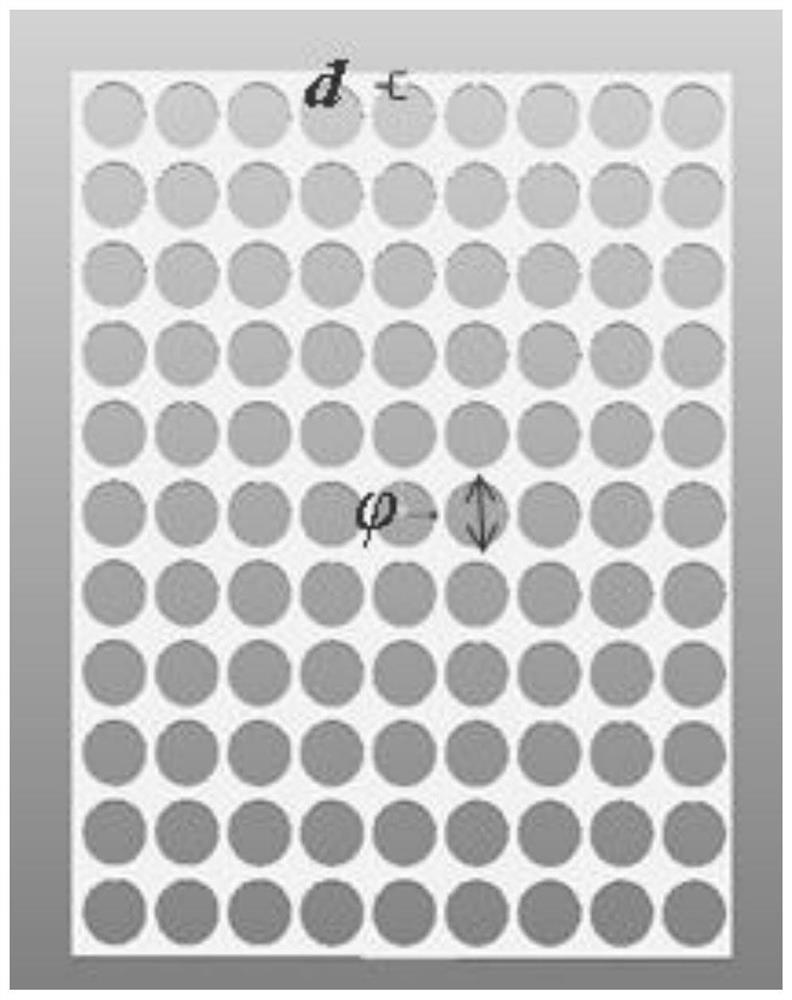

[0054] Example 1 Preparation of periodic multi-directional thickness gradient iron film under grating mask

[0055] (1) Preparation of composite substrate: spin-coated a layer of PDMS (polydimethylsiloxane) with a thickness of 16 μm on the glass sheet;

[0056] (2) Will be as figure 2 The grating mask shown is suspended and fixed above the composite substrate, and the mask specification is the size of the mesh w =63μm, rib width d=30μm, sputtering time 1min, the film thickness of the central area of the mesh is t=6nm, and the mesh coverage area is t=4nm; adjust the distance between the mask and the composite substrate to h=120μm, put in the splash In the vacuum chamber of the radiometer, the iron target is fixed on the cathode, and the substrate is placed on the anode facing the target surface. After vacuuming, argon gas is introduced. The background pressure of the vacuum chamber is 2x10 -4 Pa, the argon pressure during sputtering is 0.5Pa, the sputtering voltage is: 260V; the s...

Embodiment 2

[0060] Example 2 Preparation of periodic multi-directional thickness gradient iron film under grating mask

[0061] The difference between Example 2 and Example 1 is that the specifications and sputtering time of the grating mask are different: the size of the mesh w =127μm, rib width d=55μm, sputtering time 1min, film thickness in the center area of the mesh is t=6nm, and other process conditions are exactly the same. The optical microscope image of the prepared periodic multi-directional thickness gradient iron film is as follows Image 6 As shown, the film thickness is 6 nm, and the mesh period is 127 μm.

Embodiment 3

[0062] Example 3 Preparation of periodic multi-directional thickness gradient iron film under grating mask

[0063] The difference between embodiment 3 and embodiment 1 is that the specifications and sputtering time of the grating mask are different: the size of the mesh w =260μm, rib width d =75μm, sputtering time 1min, the film thickness of the central area of the mesh is t =6nm, the rest of the process conditions are exactly the same, the optical microscope image of the prepared periodic multi-directional thickness gradient iron film is as follows Figure 7 As shown, the film thickness is 6 nm, and the mesh period is 260 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com