Automatic assembling device for automobile cooling fan

A technology of automatic assembly device and automobile cooling, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of poor control of product quality, high risk factor, low degree of automation, etc., to ensure beautiful appearance Consistency, ensure tightening effect, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Attached below Figure 1-6 The present invention is described in detail below.

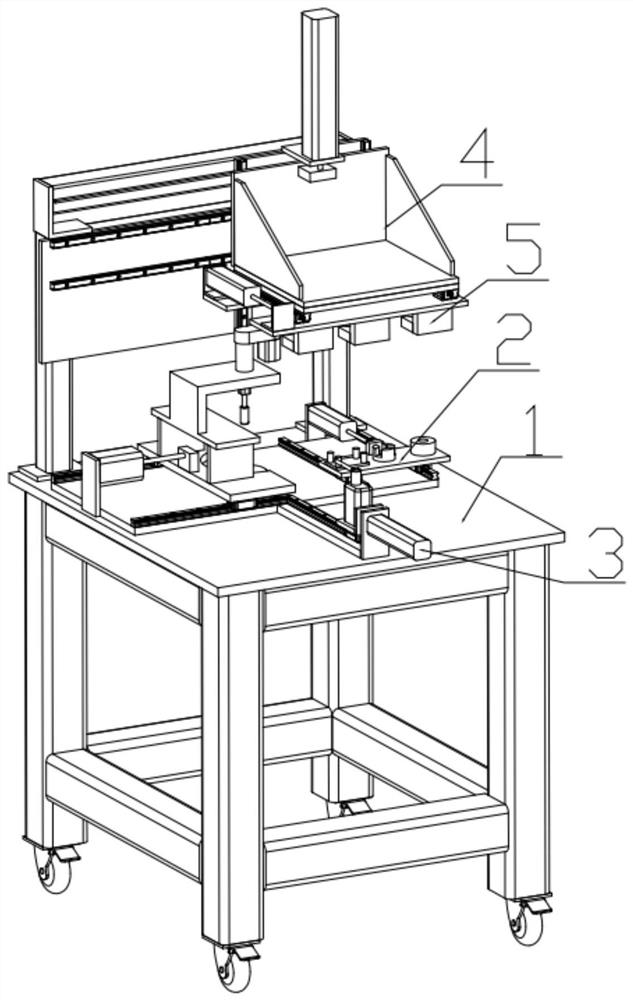

[0025] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, an automobile cooling fan assembly device includes a base frame body 1 , a feeding and tightening device 2 , an automatic welding device 3 , a traverse device 4 , and a grasping device 5 .

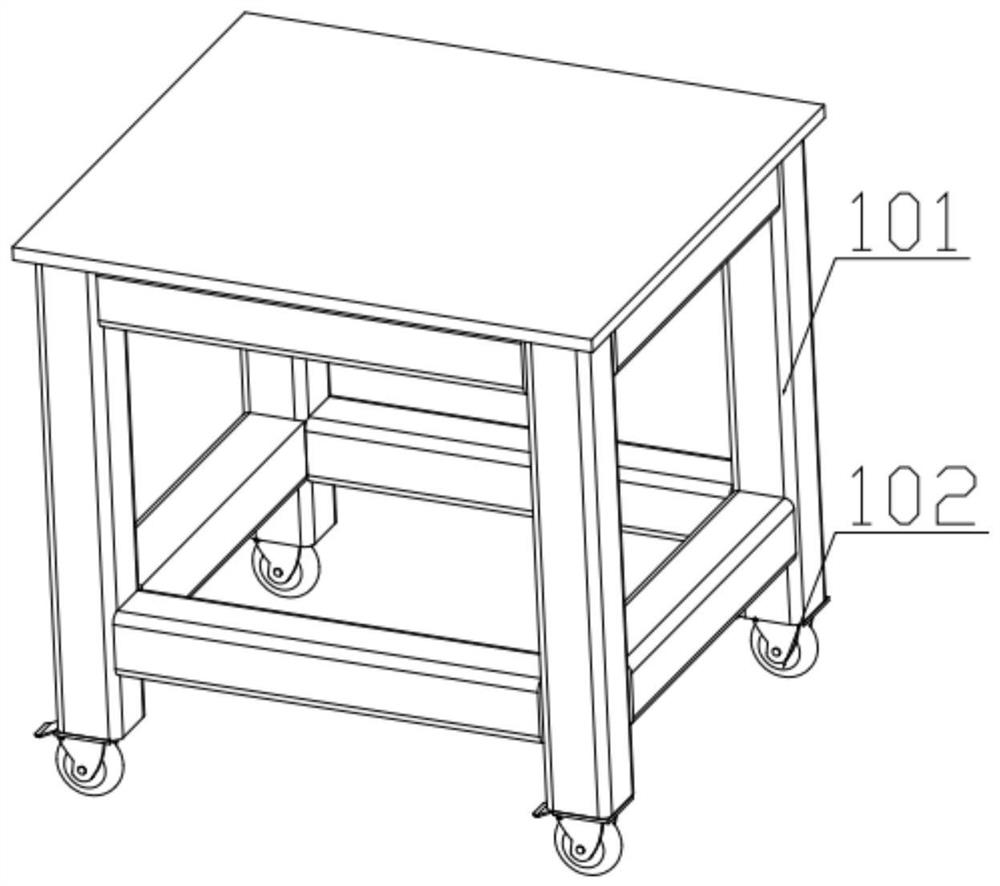

[0026] The specific structure of the base frame body 1 is as follows: figure 2 As shown, a base 101 and a movable caster 102 are included, and the movable caster 102 is installed and fixed on the bottom surface of the base 101 .

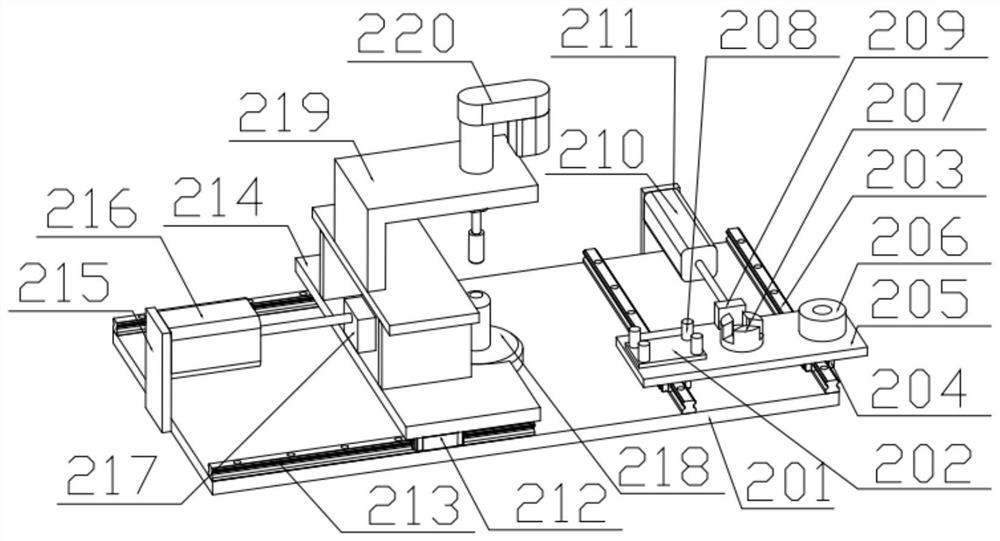

[0027] The specific structure of feeding tightening device 2 is as follows: image 3 As shown, it includes a feeding tightening device mounting plate 201, a housing positioning plate 202, a feeding device sliding guide rail 203, a feeding device slider 204, a feeding device positioning block mounting plate 205, a feeding device fan blade positioning block 206, an upper Feeding d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com