Laser cutting machine for separating and processing metal pipe fittings

A technology of laser cutting machine and metal pipe fittings, applied in the field of pipe processing, can solve the problems of low laser cutting efficiency and difficulty in solving the opening and closing of the rotating clamping mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make it easy to understand the technical means, creation features, achieved goals and effects of the present invention, the present invention will be further described below with reference to the specific figures.

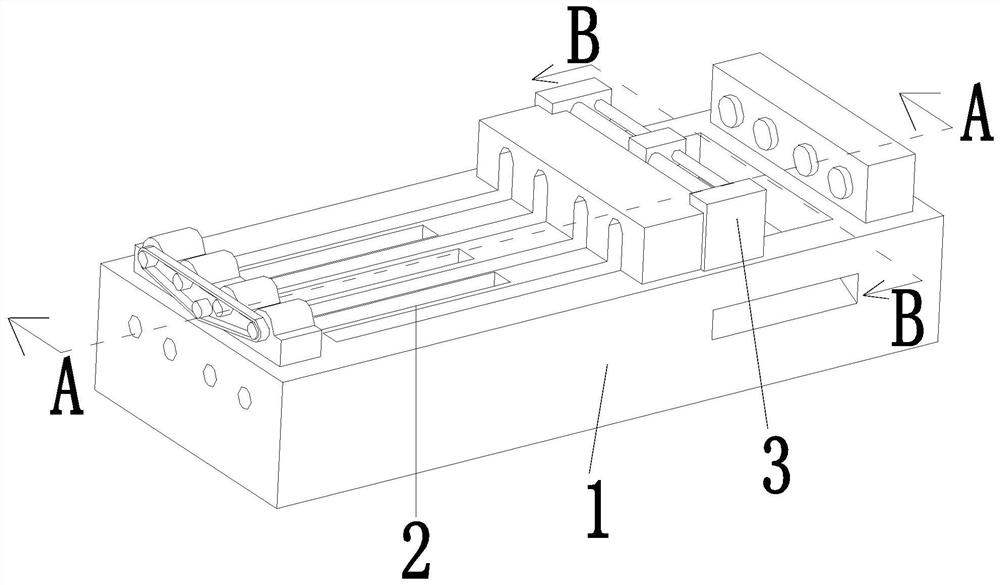

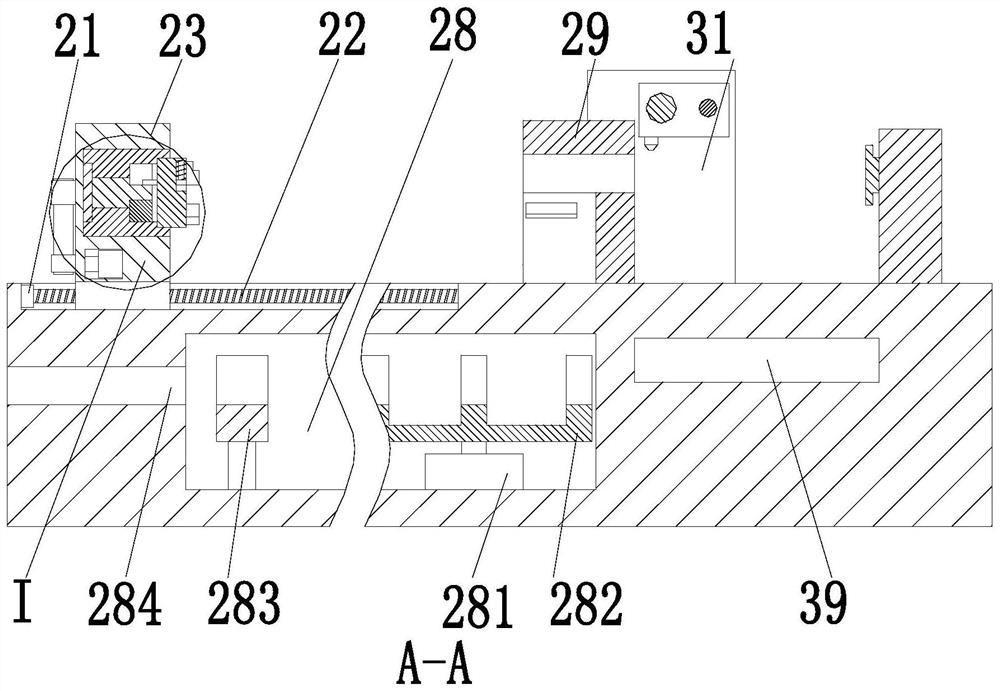

[0027] like Figure 1 to Figure 6 As shown in the figure, a laser cutting machine for separating and processing metal pipe parts includes a base 1, a feeding and fixing unit 2 and a cutting and unloading unit 3. A cutting and unloading unit 3 is provided; the loading and fixing unit 2 simultaneously feeds multiple metal pipes to a fixed position, then clamps and fixes multiple metal pipes at the same time, and drives multiple metal pipes to rotate at the same time, cutting and blanking Unit 3 performs laser cutting on the rotating metal pipe, and the cut pipe is guided for blanking.

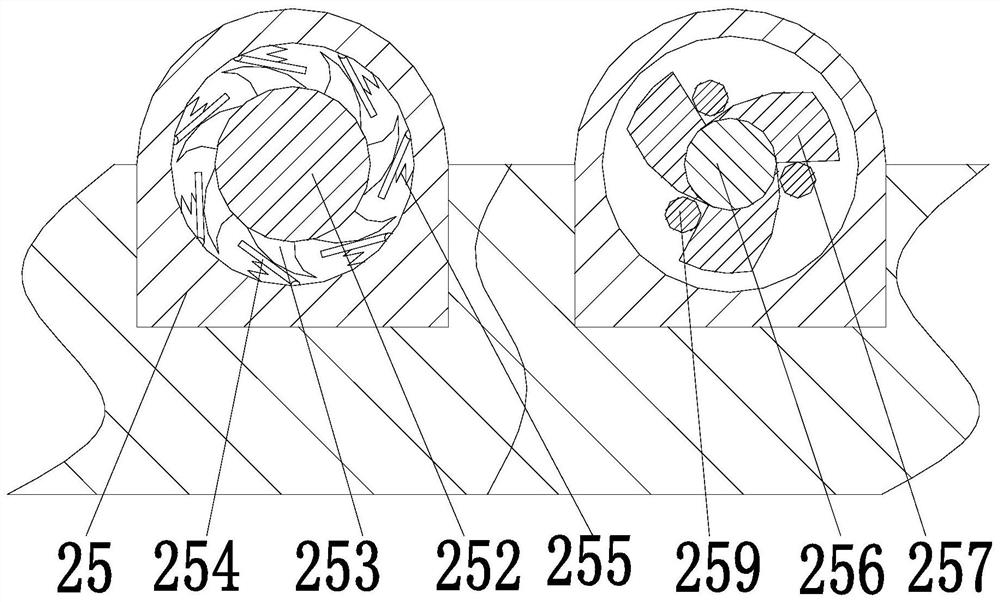

[0028] The feeding and fixing unit 2 includes a driving motor 21, a threaded column 22, a feeding frame 23, an auxiliary motor 24, a rotating mechanism 25, a drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com