Thermal compensation type injection reaction system

A technology of reaction system and jet reactor, which is applied in the chemical industry, can solve the problems of application limitation, incapability of self-consumption of heat, lack of thermal compensation function, etc., to reduce the temperature rise of the system, improve the reaction effect, and avoid the temperature rise of the system Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

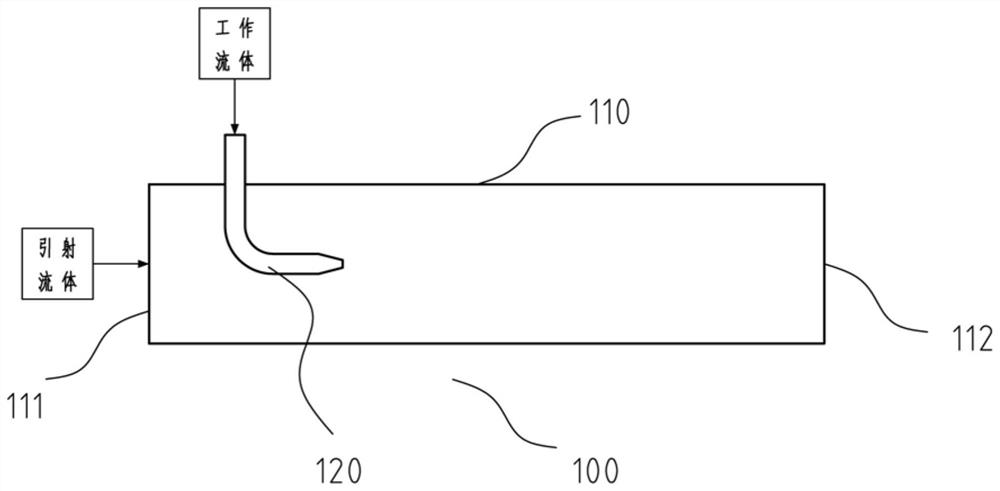

[0036] This embodiment provides a thermally compensated injection reaction system, such as figure 1 As shown, it includes a jet reactor 100, a working fluid, and an injection fluid. The jet reactor 100 includes a body 110 and a nozzle 120. The body 110 is provided with an injection fluid inlet 111 and a reactor outlet 112. The working fluid is sprayed into the body 110 through the nozzle 120, and the injection fluid enters the body 110 through the injection fluid inlet 111, and the working fluid and the injection fluid are mixed under the jet entrainment and generate heat Chemical reaction, in which at least one of the working fluid or the ejection fluid undergoes a gasification process, the latent heat of gasification required for the gasification process is compensated by the reaction heat of the exothermic chemical reaction, and the gasified and reacted material It is discharged from the reactor outlet 112.

[0037] In this embodiment, the nozzle 120 is a single nozzle typ...

Embodiment 2

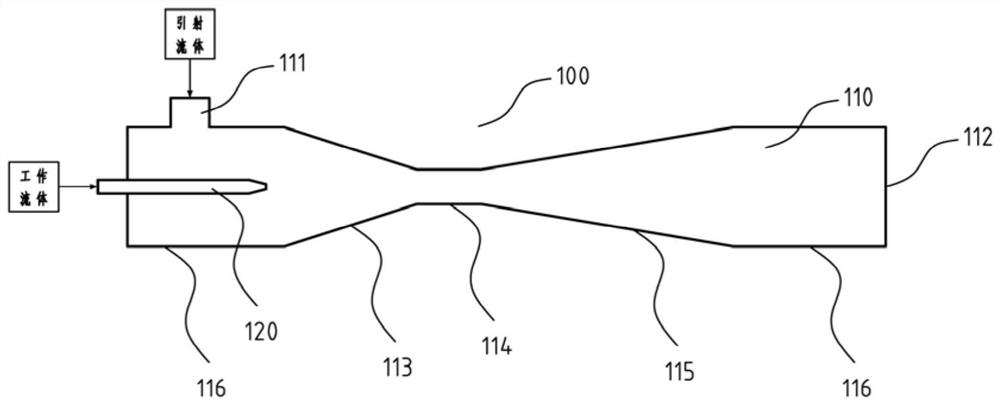

[0040] This embodiment provides a thermally compensated injection reaction system, such as figure 2 As shown, it includes a jet reactor 100, a working fluid, and an injection fluid. The jet reactor 100 includes a body 110 and a nozzle 120. The body 110 is provided with an injection fluid inlet 111 and a reactor outlet 112. The working fluid is sprayed into the body 110 through the nozzle 120, and the injection fluid enters the body 110 through the injection fluid inlet 111, and the working fluid and the injection fluid are mixed under the jet entrainment and generate heat Chemical reaction, in which at least one of the working fluid or the ejection fluid undergoes a gasification process, the latent heat of gasification required for the gasification process is compensated by the reaction heat of the exothermic chemical reaction, and the gasified and reacted material It is discharged from the reactor outlet 112.

[0041] In this embodiment, the nozzle 120 is a single nozzle ty...

Embodiment 3

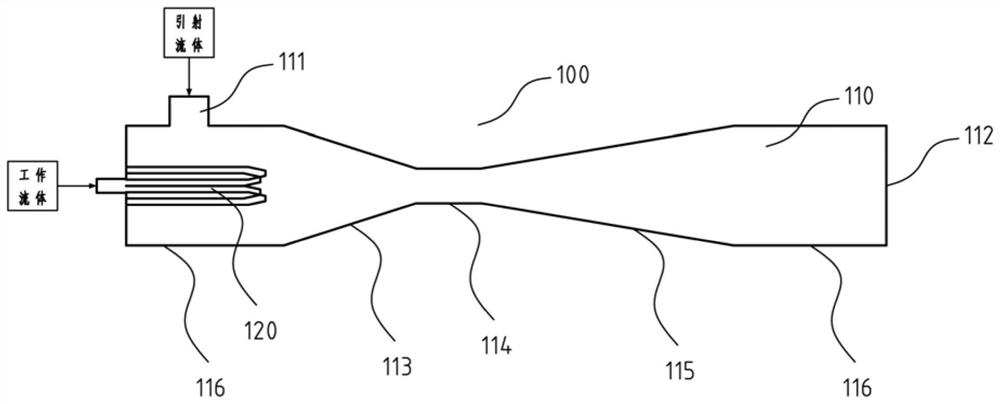

[0044] This embodiment provides a thermally compensated injection reaction system, such as image 3 As shown, it includes a jet reactor 100, a working fluid, and an injection fluid. The jet reactor 100 includes a body 110 and a nozzle 120. The body 110 is provided with an injection fluid inlet 111 and a reactor outlet 112. The working fluid is sprayed into the body 110 through the nozzle 120, and the injection fluid enters the body 110 through the injection fluid inlet 111, and the working fluid and the injection fluid are mixed under the jet entrainment and generate heat Chemical reaction, in which at least one of the working fluid or the ejection fluid undergoes a gasification process, the latent heat of gasification required for the gasification process is compensated by the reaction heat of the exothermic chemical reaction, and the gasified and reacted material It is discharged from the reactor outlet 112.

[0045] In this embodiment, the nozzle 120 is a multi-nozzle type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com