Active coke combined desulfurization and denitrification system and method based on pre-oxidation

A technology of desulfurization, denitrification and activated coke, which is applied in the field of flue gas purification, can solve problems such as low oxidation efficiency, and achieve the effects of improving treatment efficiency, reducing oxygen content and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with specific embodiments, which are to explain rather than limit the present invention.

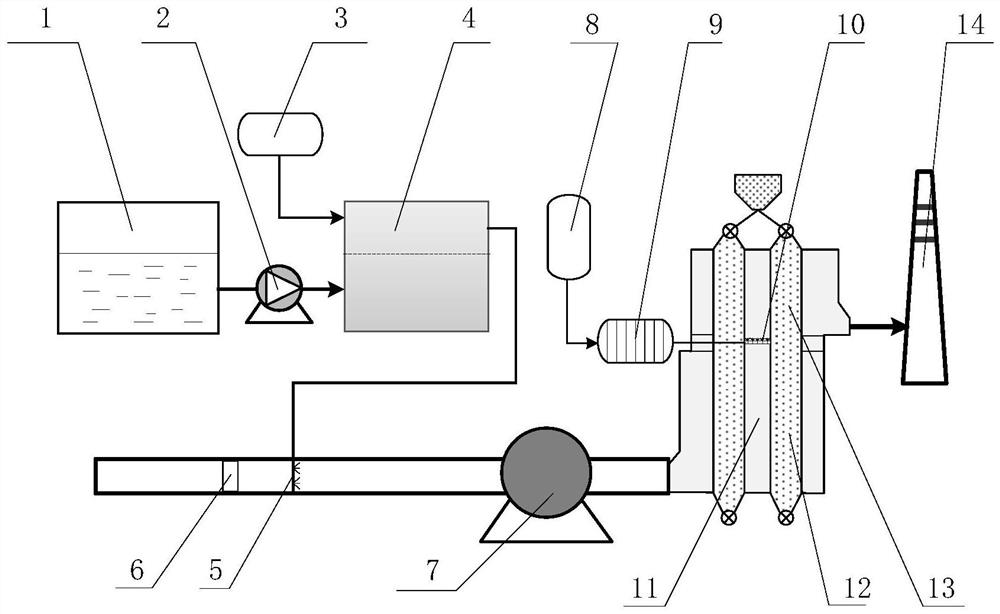

[0035] The present invention is an activated coke combined desulfurization and denitration system based on pre-oxidation, such as figure 1 Shown, including the pre-oxidation system, absorption system and chimney three parts. The pre-oxidation system includes H 2 O 2 Storage tank 1, transfer pump 2, ultrasonic atomizer 4; the absorption system includes an absorption tower 11, a desulfurization section 12 arranged in the lower section of the absorption tower 11, a denitration section 13 arranged in the upper section of the absorption tower 11, and an absorption tower 11 The ammonia injection grid 10 of the internal intermediate air chamber is connected to the ammonia evaporator 9 and the ammonia storage tank 10 which are connected to the ammonia injection grid 10 in turn.

[0036] H after atomization 2 O 2 It ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com