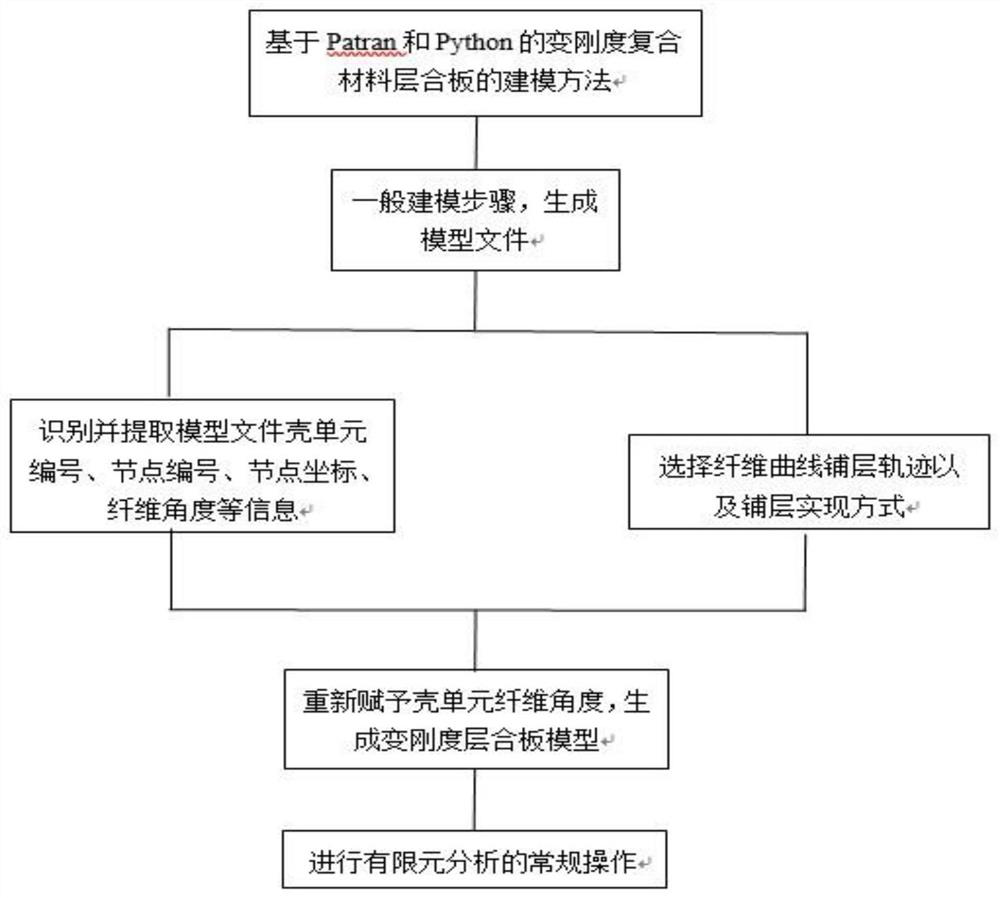

Finite element modeling method for variable stiffness composite laminate

A laminated board and variable stiffness technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems that affect research progress, trouble, errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

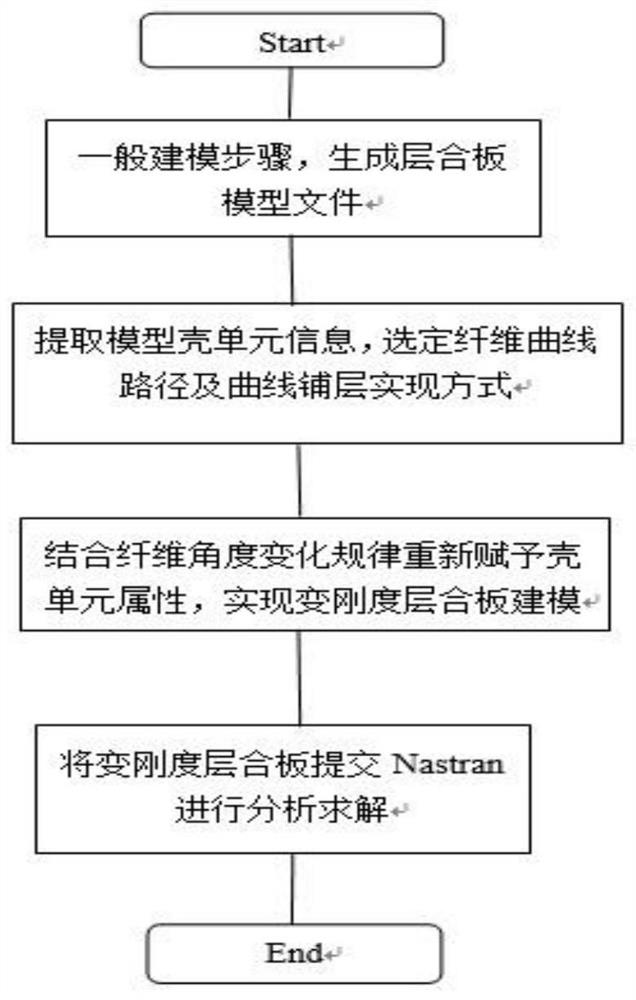

[0023] This embodiment is a finite element modeling method of a variable stiffness composite material laminate.

[0024] refer to figure 1 , figure 2 , the finite element modeling method of variable stiffness composite laminates in this embodiment, based on the above-mentioned operation steps of variable stiffness laminates, the following gives the layup as [±]s, and uses the translation method to realize the curve laying Layers of variable stiffness laminates are described in detail for specific examples.

[0025] The first step is to establish a complete four-layer laminate model in Patran according to the general steps. The lay-up angles of the four single layers are given arbitrarily and submitted for analysis to generate a model file. The fiber angle of the curved ply is , that is, the middle fiber angle of a single layer is 30°, the edge fiber angle is 0°, and the fiber angle is symmetrical about the midpoint. For the convenience of calculation, a local coordinate sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com