ARO soldering pliers fault detection method

A technology of fault detection and welding tongs, which is applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of not effectively reflecting the grinding effect, having too many plug interfaces and measurement data, and increasing the judgment time, so as to achieve shortening The effect of fault handling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] The automatic spot welding system is mainly composed of ARO automatic welding tongs, welding control cabinet, robot and connecting water and gas cables. ARO welding tongs are mainly composed of a servo motor to drive the electrode arm to move and clamp to generate welding pressure), a rotating shaft, a static electrode arm, a moving electrode arm, an electrode rod, an electrode head, a gun body, and a transformer.

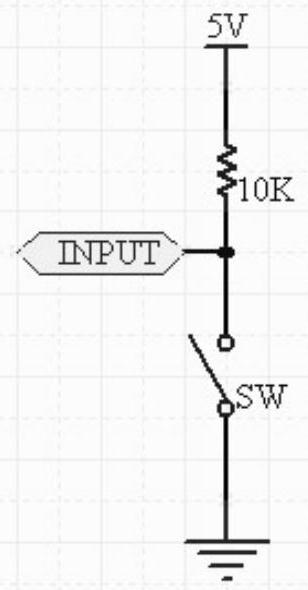

[0042] The control cabinet mainly adopts Bosch6000 series, and the cabinet is mainly composed of PSI controller, air switch, relay, and leakage protection device. The core component is the PSI controller ( Figure 1-3 ), the PSU side is the PSI controller side, and the PSG is the welding clamp side (transformer, diode, etc.). Three-phase 380V input, through bridge rectification, forms a DC circuit, and then undergoes inverter, boost, and frequency conversion to form a single AC output. The voltage at the input port of the transformer is 500-550V, 1000HZ. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com