In-hole explosive charging structure for controlling blasting toe rock and construction method of in-hole explosive charging structure

A technology for controlling blasting and construction methods, which is applied in blasting and other directions, and can solve problems such as the difficulty of controlling the blasting root, achieve the effects of ensuring the crushing and throwing effect, reducing the large block rate of the orifice, and enhancing the crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

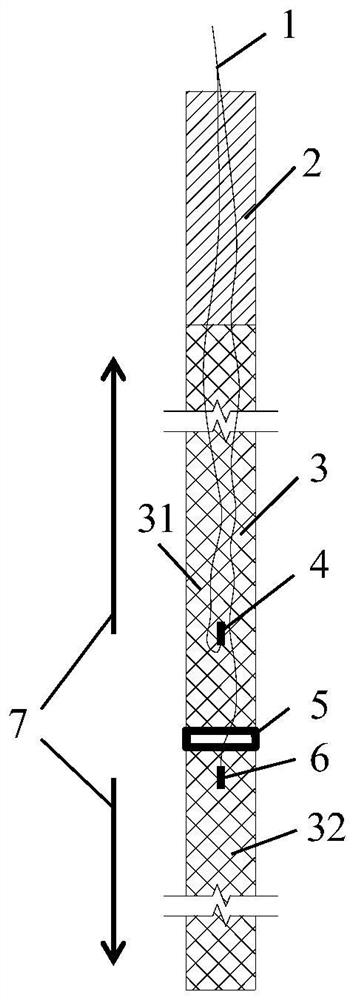

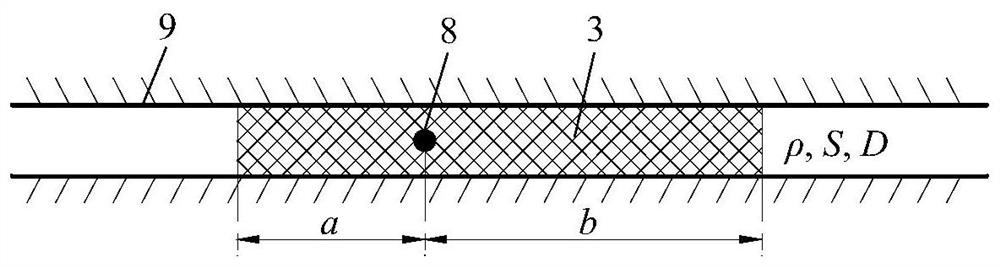

[0039] The preparation of the inert interlayer 5 can be determined according to the site conditions, as long as it is ensured that the explosives in the upper and lower sections of the interlayer do not explode each other, preferably, the inert interlayer 5 adopts inert materials such as airbags, sandbags or sandbags; The axial dimension of the inert interlayer 5 along the blast hole is 1.5-2 times the distance of the explosive detonation, and the diameter of the inert interlayer 5 is 0.85 to 0.95 times the diameter of the blast hole.

[0040] The length of the blocking section 2 is 0.9 to 1.0 times of the minimum resistance line 13; when the finished drug roll is used in the upper charge section 31 or the lower charge section 32, the uncoupled charge is used, and the uncoupling coefficient is 1.2 to 1.5; When the upper charge section 31 or the lower charge section 32 adopts on-site mixed charge, the coupled charge is used.

[0041] The charge structure in the hole for control...

Embodiment

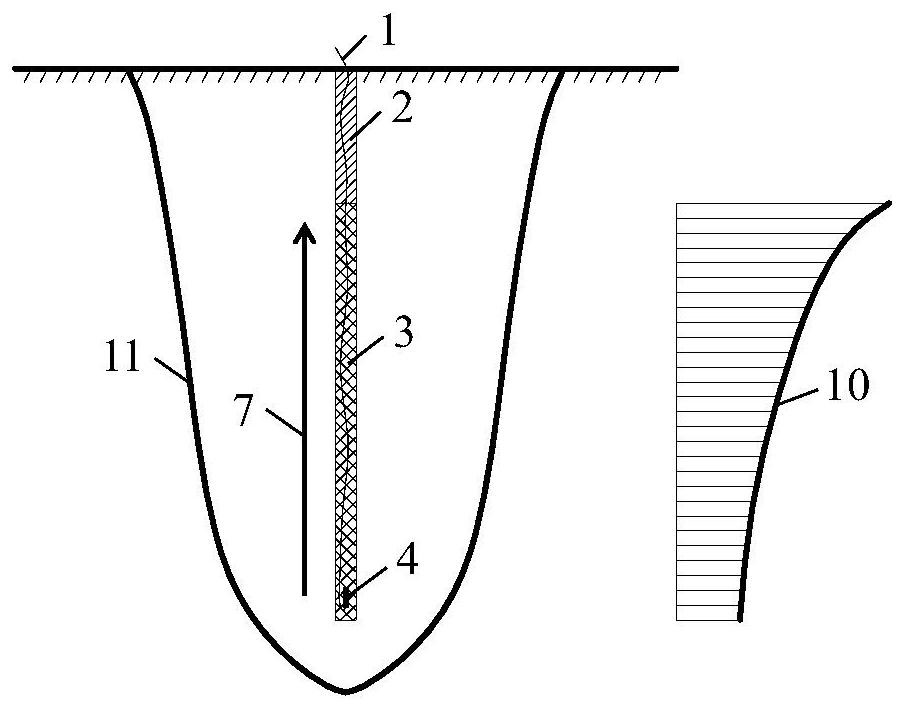

[0061] During the construction of a petrochemical base, a large amount of earth and stone excavation was involved, and the method of deep hole step blasting was mainly used. The height of the steps in conventional blasting is 13.0m, the holes are arranged in a quincunx shape, the row spacing between the blastholes is 6.0m×3.5m, the diameter of the blastholes is 115mm, the inclination angle α is 80°, the drilling depth is 14.5m, and the charge length is 9.0m. The explosives used are 2# rock emulsion explosives, and the finished product rolls.

[0062] Adopt a kind of charging structure in the hole that is used for controlling blasting root of the present invention, concrete method comprises the following steps:

[0063] (1) Drilling blast holes: According to the blasting design requirements, drill blast holes up to the design elevation, and reserve 20-30cm of over-drilling.

[0064] (2) Hole forming quality inspection and hole bottom leveling: first check the hole forming qual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com