Biomass power generation system

A biomass power generation and component technology, which is applied in the direction of biofuel, steam generation, machine/engine, etc., can solve the problems that the capacity of the furnace cannot be adjusted, and the heat of biomass combustion cannot be fully utilized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

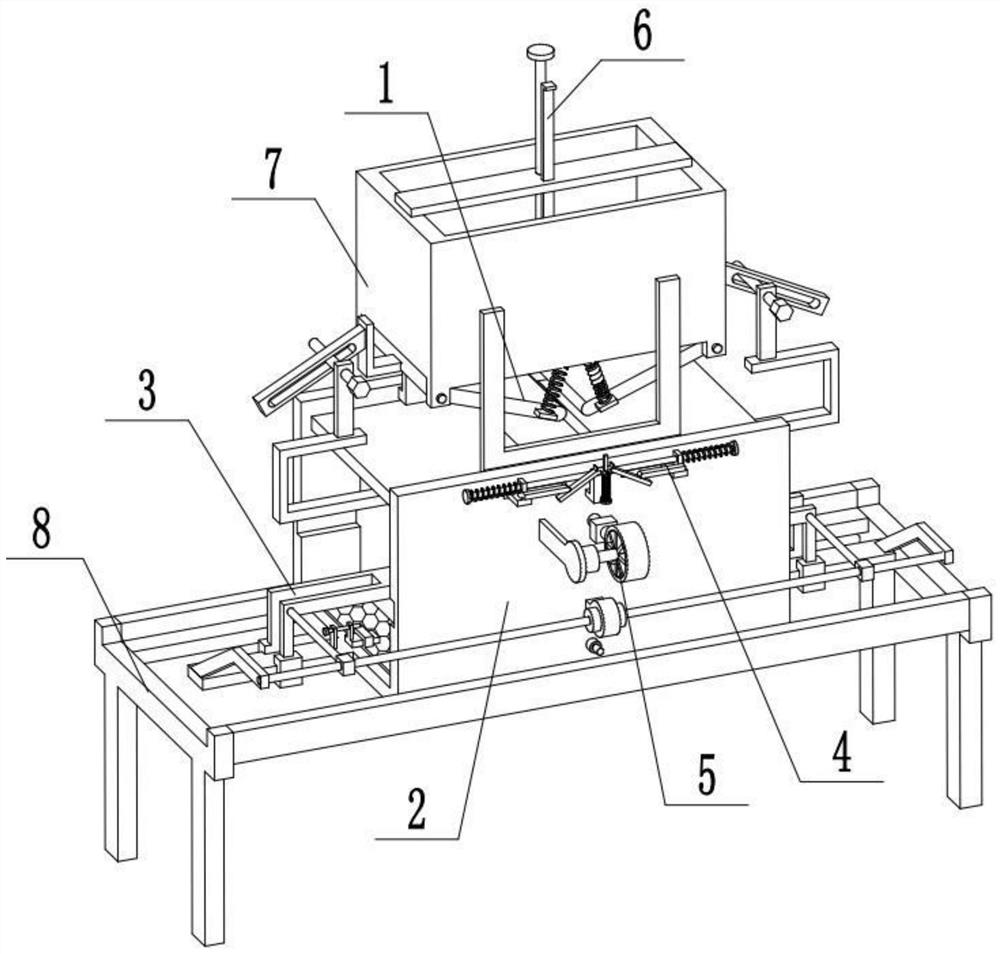

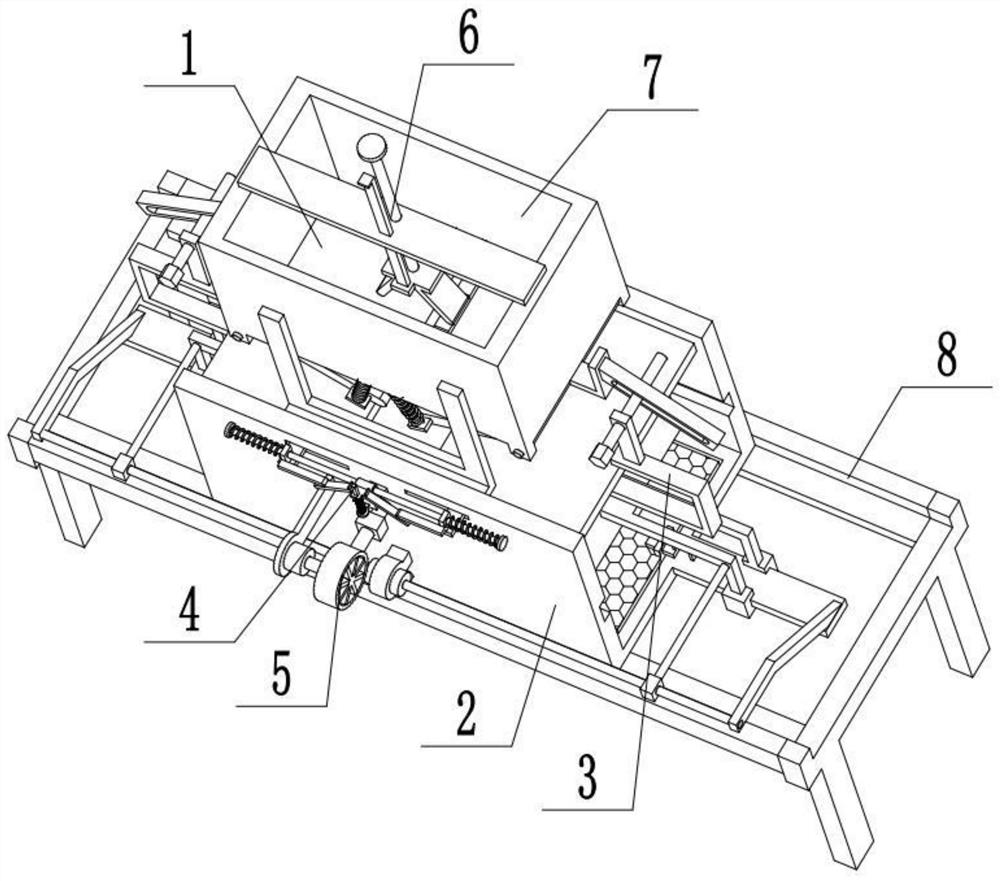

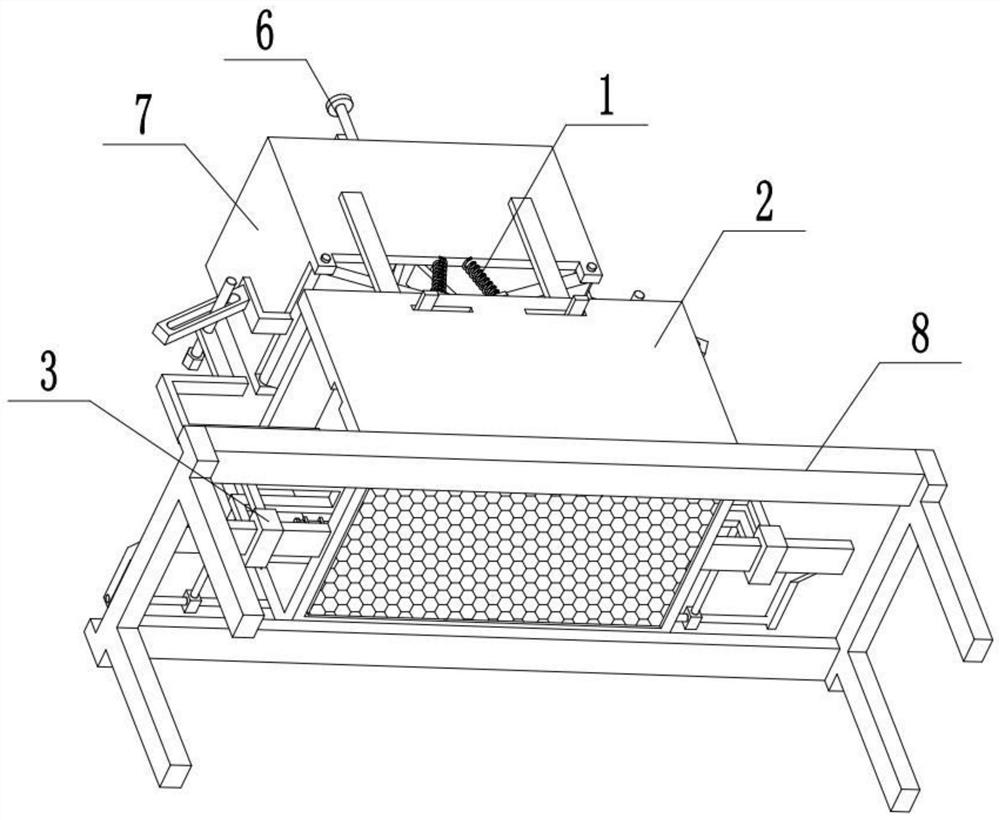

[0030] Combine below Figure 1-10Describe this embodiment, a biomass power generation system, including a discharge assembly 1, a combustion furnace assembly 2, an adjustable furnace wall assembly 3, an upper baffle assembly 4, a power conversion device 5, a push plate 6, and a feed box 7 And underframe 8, described discharge assembly 1 is provided with two, and two discharge assemblies 1 are symmetrically arranged on the lower end of feeding box 7, and feeding box 7 is fixedly connected on the combustion furnace assembly 2 by U-shaped plate, The combustion furnace assembly 2 is fixedly connected to the bottom frame 8, and the adjustable furnace wall assembly 3 is connected to the combustion furnace assembly 2. The two ends of the adjustable furnace wall assembly 3 are respectively connected with the two discharge assemblies 1, and the upper baffle The assembly 4 is arranged on the upper end of the combustion furnace assembly 2 , the power conversion device 5 is arranged on th...

specific Embodiment approach 2

[0032] Combine below Figure 1-10 To illustrate this embodiment, the discharge assembly 1 includes a lower baffle 1-1, a long shaft 1-2, an L-shaped connecting rod 1-3, a grooved rod 1-4, a spring seat 1-5 and a first spring 1 -6; the lower baffle plate 1-1 is fixedly connected to the long shaft 1-2, the long shaft 1-2 is rotatably connected to one side of the lower end of the feed box 7, and the outer end of the long shaft 1-2 is fixedly connected to the L-shaped connecting rod 1-3, the groove rod 1-4 is fixedly connected to the L-shaped connecting rod 1-3, and the adjustable furnace wall assembly 3 is connected with the groove rod 1-4; the inner end of the lower baffle 1-1 is fixedly connected symmetrically Two spring seats 1-5 are respectively fixedly connected with a first spring 1-6, and the two first springs 1-6 are fixedly connected to the bottom surface of the feeding box 7. In use, when the adjustable furnace wall assembly 3 is adjusted to change the furnace space, t...

specific Embodiment approach 3

[0034] Combine below Figure 1-10 To illustrate this embodiment, the combustion furnace assembly 2 includes a bottom frame 2-1, a side fixed wall 2-2, an upper through groove 2-3, an inner chute 2-4, an ignition device 2-5, and a side sliding rod 2 -6. Barrel 2-7 and fire grate 2-8; the bottom frame 2-1 is fixedly connected to the bottom frame 8, and the two ends of the bottom frame 2-1 are respectively fixedly connected to a side fixed wall 2-2, two side The upper end of the fixed wall 2-2 is respectively provided with one or two upper through grooves 2-3, and the middle part of the inner wall of the two side fixed walls 2-2 is respectively provided with two inner chute 2-4, and the side fixed wall 2-2 of the front end The lower end of the bottom frame is provided with an ignition device 2-5, and the power generation conversion device 5 is located at the upper end of the fixed wall 2-2 on the front end side, and the power generation conversion device 5 is located at the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com