Adjustable oil-gas hybrid engine

An adjustable, engine technology that can be used in engine components, machines/engines, valve details, etc. to solve problems such as low power and insufficient oil combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

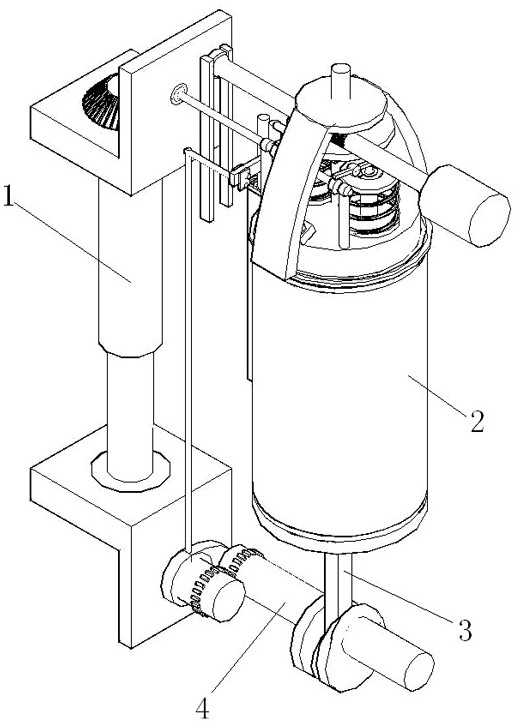

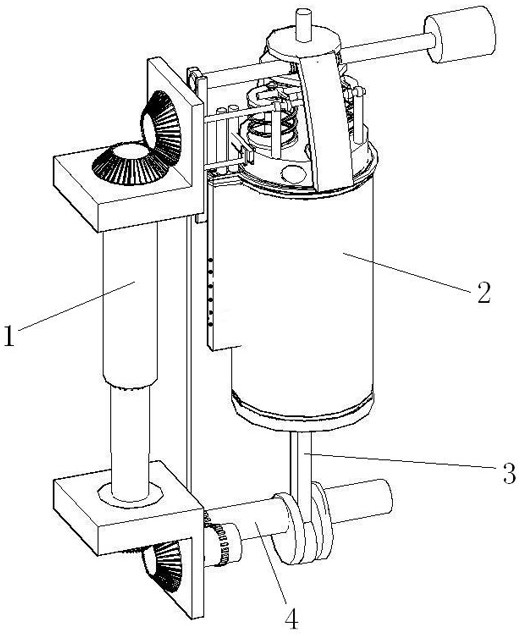

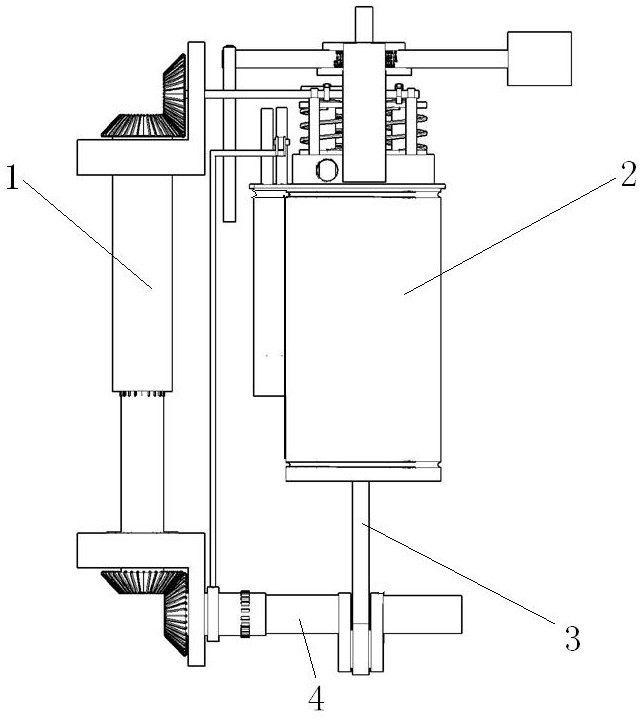

[0034] The specific implementation, structure, features and effects according to the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

[0035] A variable-cylinder engine capable of adjusting the mixing amount of oil and gas according to the present invention is characterized in that: the upper part of the side of the gas distribution mechanism 1 is inserted into the cylinder liner 2, the lower part of the side is connected to the crankshaft 4, and a connecting rod 3 is installed on the crankshaft 4, and the connecting rod 3 passes through the piston. Pin 5 is connected to piston 6 .

[0036]The gas distribution mechanism 1 is composed of a cylinder head 7, an eccentric shaft A8, an oil injection nozzle 9, an eccentric shaft B10, a support A11, a push rod 12, a telescopic shaft 13, an air release valve A14, a telescopic sleeve 15, an air release valve B16, and a support B17, bevel gear A18, bracket C19, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com