Frame-sealing glue, manufacture method for liquid crystal display panel and liquid crystal display panel

A technology for a liquid crystal display panel and a manufacturing method, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of uneven compression, easily scratched TFT substrate circuits, and difficult to control the compression rate, and achieves the thickness and edge of the liquid crystal cell. Reasonable box thickness, excellent display performance, and controllable compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

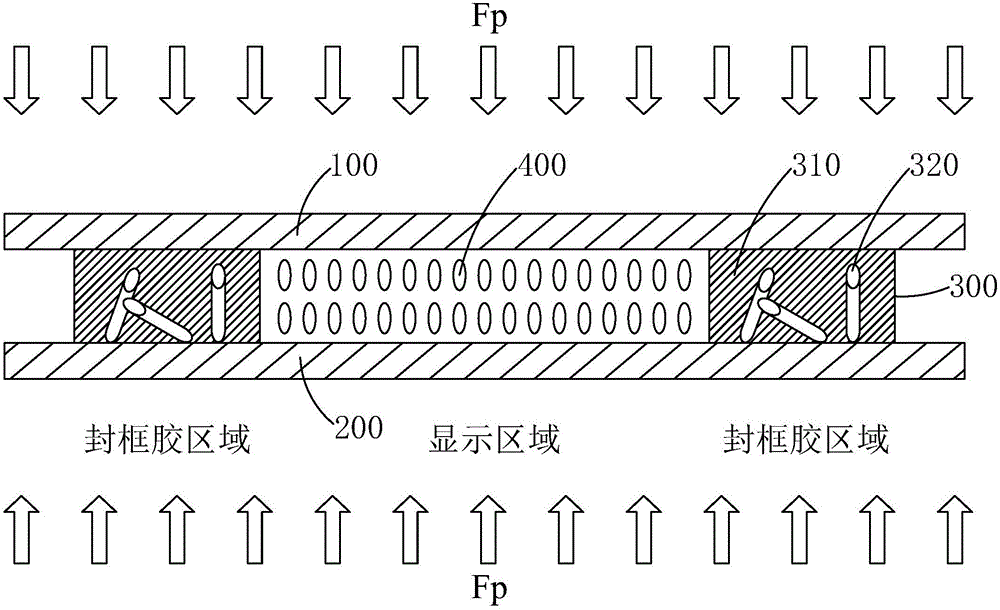

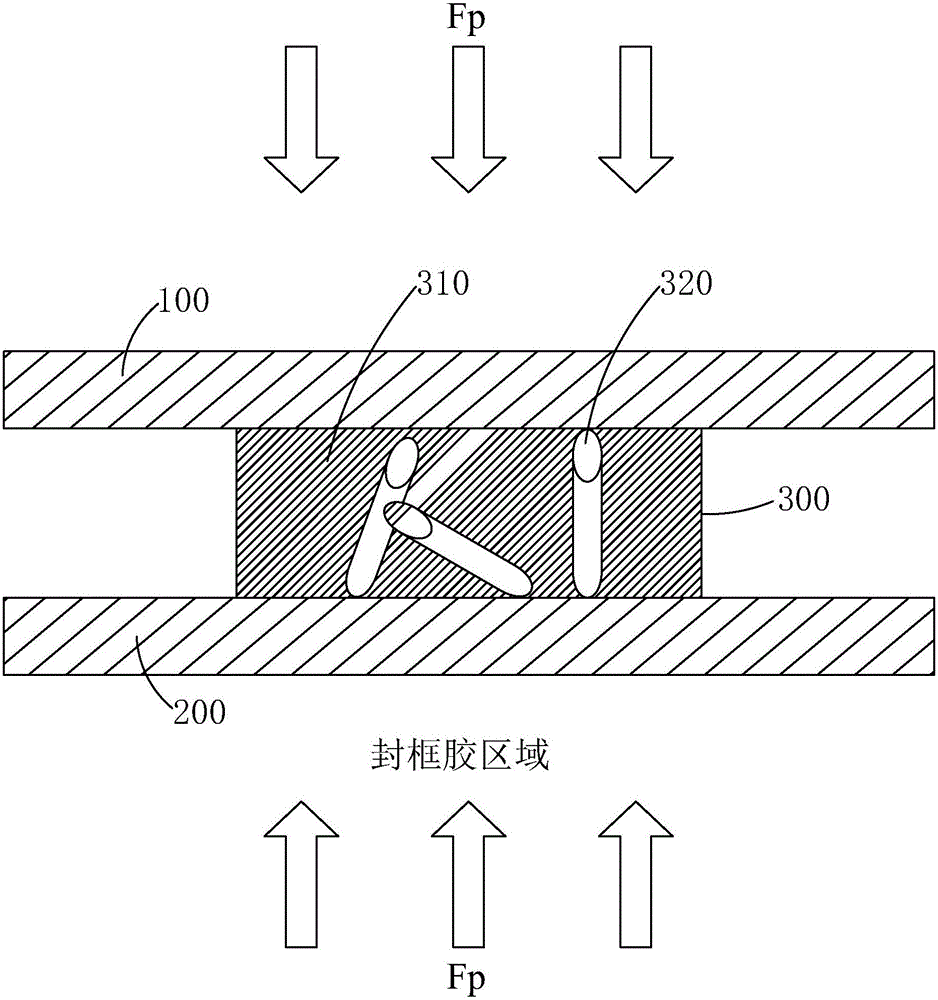

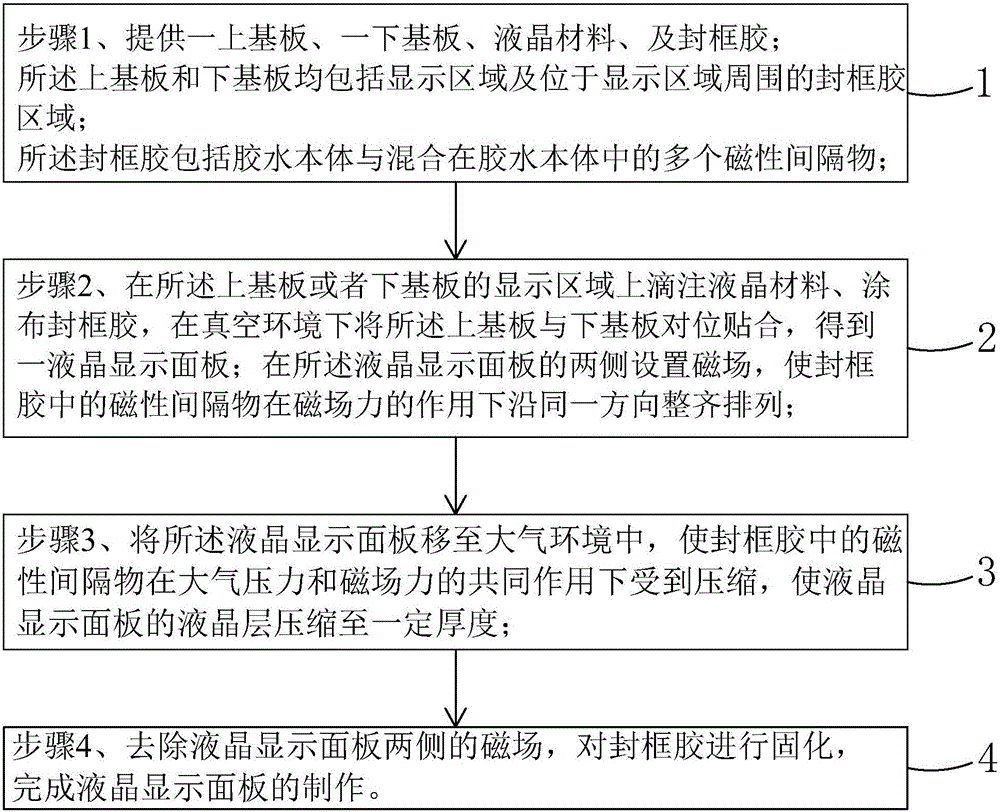

[0039] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

[0040] see Figure 4 The present invention firstly provides a frame sealing glue 40, comprising a glue body 41 and a plurality of magnetic spacers 42 mixed in the glue body 41; the magnetic spacers 42 include a rod body 421, and two The end 422 ; the rod body 421 and the end 422 are both made of elastic magnetic polymer material, and the two ends 422 are N pole and S pole respectively.

[0041] Specifically, the radial dimension of the end portion 422 is larger than the radial dimension of the rod body 421 , and the surfaces of the two ends 422 are arc-shaped surfaces protruding toward the side away from the rod body 421 . In this way, the magnetic spacer 42 can be more easily controlled by external force and will not cause damage to the circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com