Compression device for gas valve springs

A technology of air valve spring and compression device, which is applied in the field of machinery, can solve the problems of inconvenient carrying and use, flying out of air valve blocks and hurting people, and slipping of pressing tools, so as to achieve easy assembly, stable spring compression, and reduce The effect of installs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

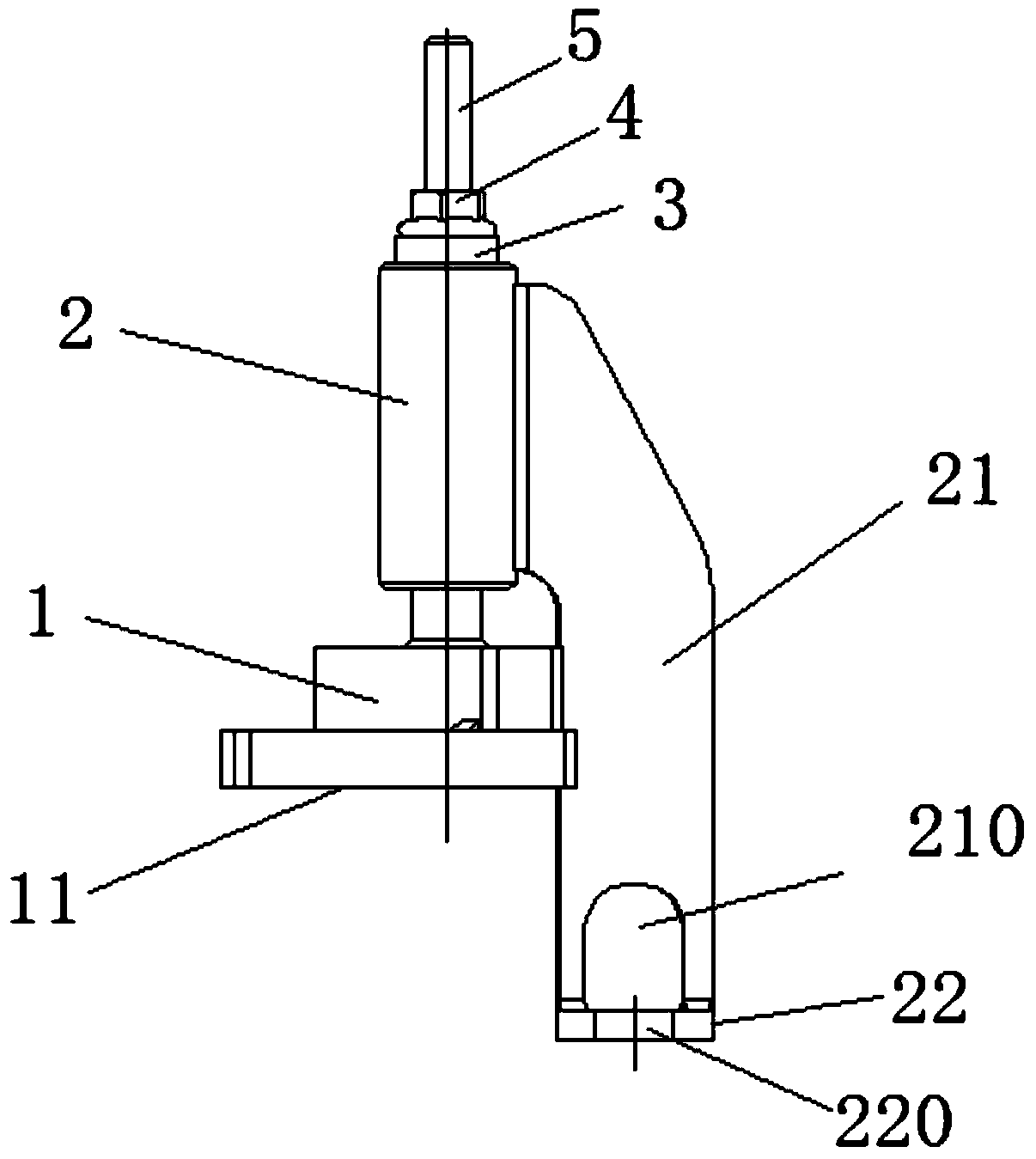

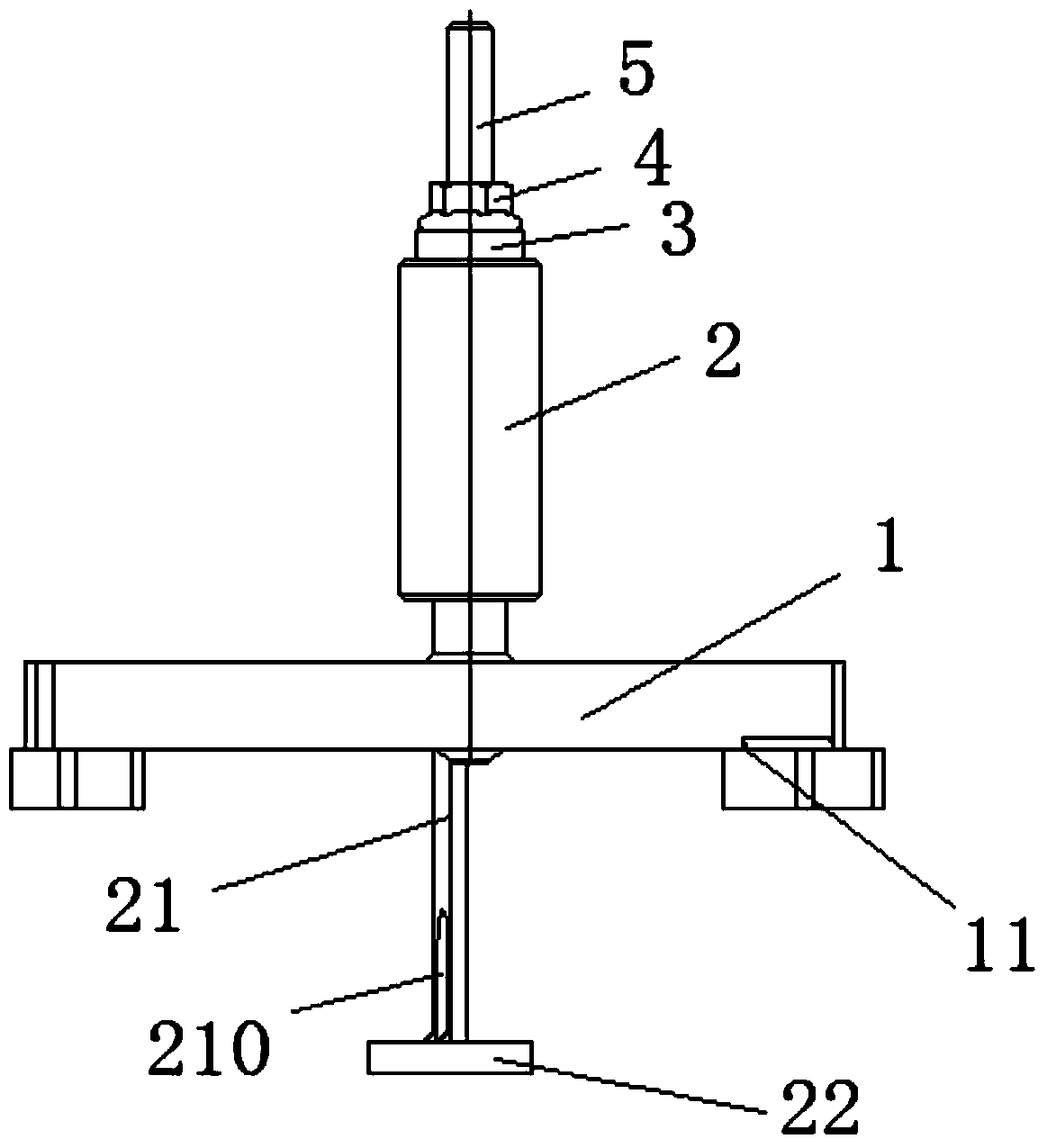

[0014] Such as figure 1 with figure 2 The shown pressing device for the air valve spring includes a stud 5, the lower end of which is provided with a rounded chamfer, which is convenient for installation, and the stud 5 is sequentially installed with a bracket 1, a stop Push column 2, washer 3 and nut 4, described support 1 is elongated, and is symmetrically distributed along the left and right sides of stud 5, and the bottom of this support 1 two ends is respectively provided with a fixed block 11, and nut is installed on this fixed block 11 .

[0015] The side of the thrust column 2 is provided with a rotating arm 21, the rotating arm 21 is in the shape of a half "C" and protrudes below the support 1, and an inverted U-shaped slot 210 is arranged below the rotating arm 21, and the U-shaped locking The lower end of the groove 210 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com