Clovershrub cold process soap and preparation method thereof

A technology of Dahongpao and cold-making soap, applied in the directions of chemical instruments and methods, soap detergents and other compounding agents, preparations for skin care, etc., to achieve the effects of high economic efficiency, high production efficiency and good nourishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

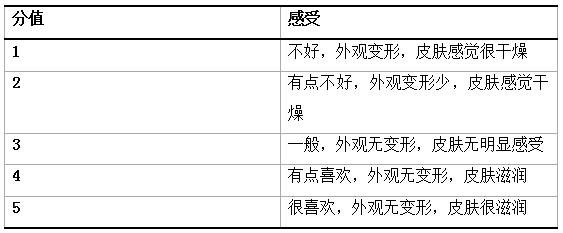

Image

Examples

Embodiment 1

[0024] A Dahongpao tea seed oil cold-processed soap, the amount of raw materials per 100g of finished handmade soap is as follows: tea seed oil: 70g; lye: 30g; tea leaves: 1g.

[0025] The lye is 1 / 3 sodium hydroxide tea soup solution. The preparation method of the tea soup is as follows: adding Dahongpao tea leaves into distilled water at 100° C. with a mass volume ratio of 1:20, soaking for 15 minutes, filtering the tea leaves, and standing at room temperature.

[0026] The preparation method of this tea seed oil handmade soap is as follows:

[0027] (1) Weigh 1g of Dahongpao tea leaves, and put the Dahongpao tea leaves in an oven at 60°C for 30 minutes.

[0028] (2) Weigh the tea seed oil into the corresponding container according to the formula, put the Dahongpao that has completed step (1) into the tea seed oil, shake it for 6 hours, and then let it stand for 7 days.

[0029] (3) Filter the mixed liquid of Dahongpao and tea seed oil after completing step (2) to remove t...

Embodiment 2

[0035] A Dahongpao tea seed oil cold-processed soap, the amount of raw materials per 100g of finished handmade soap of the tea seed oil handmade soap is as follows: tea seed oil: 65g; lye: 35g; tea leaves: 1g.

[0036] The lye is 1 / 3 sodium hydroxide tea soup solution. The preparation method of the tea soup is as follows: adding Dahongpao tea leaves into distilled water at 100° C. with a mass volume ratio of 1:20, soaking for 15 minutes, filtering the tea leaves, and standing at room temperature.

[0037]The preparation method of this tea seed oil handmade soap is as follows:

[0038] (1) Weigh 1g of Dahongpao tea leaves, and put the Dahongpao tea leaves in an oven at 60°C for 30min.

[0039] (2) Weigh the tea seed oil into the corresponding container according to the formula, put the Dahongpao that has completed step (1) into the tea seed oil, shake it for 6 hours, and then let it stand for 7 days.

[0040] (3) Filter the mixed liquid of Dahongpao and tea seed oil in step (...

Embodiment 3

[0046] A Dahongpao tea seed oil cold-processed soap, the amount of raw materials per 100g of finished handmade soap of the tea seed oil handmade soap is as follows: tea seed oil: 60g; lye: 40g; tea leaves: 2g.

[0047] The lye is a sodium hydroxide tea soup solution with a mass fraction of 1 / 3. The preparation method of the tea soup is as follows: adding Dahongpao tea leaves into distilled water at 100° C. with a mass volume ratio of 1:20, soaking for 15 minutes, filtering the tea leaves, and standing at room temperature.

[0048] The preparation method of this tea seed oil handmade soap is as follows:

[0049] (1) Weigh 1g of Dahongpao tea leaves, and put the Dahongpao tea leaves in an oven at 60°C for 30 minutes.

[0050] (2) Weigh the tea seed oil into the corresponding container according to the formula, put the Dahongpao that has completed step (1) into the tea seed oil, shake it for 6 hours, and then let it stand for 7 days.

[0051] (3) Filter the mixed liquid of Daho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com