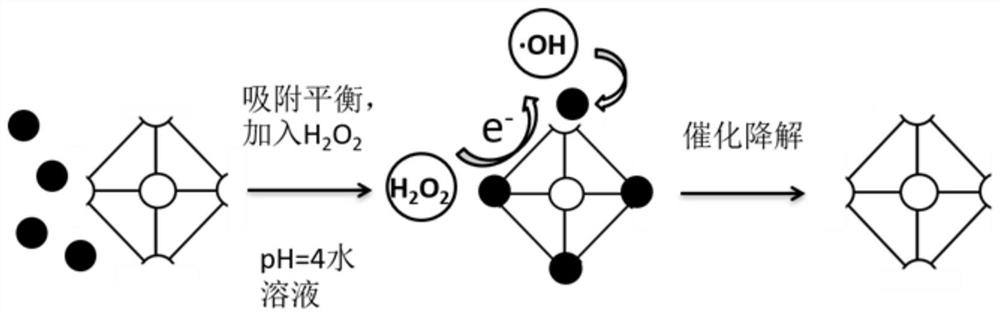

Molecular imprinting type MOFs catalyst and preparation and application thereof in specific catalytic degradation of antibiotics

A technology of molecular imprinting and catalyst, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, organic compound/hydride/coordination complex catalyst, etc. It can solve the problem of weak specific recognition ability of antibiotics and low adsorption capacity, etc. problems, to achieve high adsorption capacity performance, ultra-high specific surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: be that sulfamethazine, 2-aminoterephthalic acid and ferric chloride are placed in the 50mL conical flask that fills 15mL N-N dimethylformamide that the molar ratio is 1:1:2, Sonicate to dissolve completely. The mixture was placed in a 25mL hydrothermal reactor and reacted at 110°C for 24h. After cooling to room temperature, centrifuge at 10000 rpm for 10 min to collect the solid product in the solution. Then the solid product was stirred and eluted with ethanol at 60°C for 3 times, each time for 3h; the eluted product was centrifuged and dried at 60°C to obtain the molecularly imprinted MOFs catalyst material. No template molecules are added during the preparation of non-imprinted MOFs catalyst materials (NIP-MOFs), and the rest of the operations are consistent with the preparation process of molecularly imprinted MOFs catalyst materials.

[0036] It can be seen from the electron microscope images that the molecularly imprinted MOFs catalyst material pr...

Embodiment 2

[0037] Example 2: Put sulfamethazine, terephthalic acid and ferric nitrate at a molar ratio of 2:5:2 in a 50 mL Erlenmeyer flask filled with 15 mL of water, and ultrasonically dissolve them completely. The mixture was placed in a 25mL hydrothermal reactor and reacted at 150°C for 12h. After cooling to room temperature, centrifuge at 10000 rpm for 10 min to collect the solid product in the solution. Then the solid product was eluted with methanol at 50°C for 3 times with stirring and elution for 3 hours each time; the eluted product was centrifuged and dried at 80°C, and molecularly imprinted MOFs catalyst materials could also be obtained. No template molecules are added during the preparation of non-imprinted MOFs catalyst materials (NIP-MOFs), and the rest of the operations are consistent with the preparation process of molecularly imprinted MOFs catalyst materials.

Embodiment 3

[0038] Embodiment 3: be that sulfamethoxazole, 2-aminoterephthalic acid and ferric chloride are placed in the 50mL Erlenmeyer flask that fills 15mL N-N dimethylformamide that mol ratio is 4:2:2, ultrasonic Let it dissolve completely. The mixture was placed in a 25mL hydrothermal reactor and reacted at 130°C for 20h. After cooling to room temperature, centrifuge at 10000 rpm for 10 min to collect the solid product in the solution. Then the solid product was extracted and eluted twice with acetone at 90°C for 12 hours each time by Soxhlet extraction; the eluted product was centrifuged and dried at 70°C to obtain the molecularly imprinted MOFs catalyst material. No template molecules are added during the preparation of non-imprinted MOFs catalyst materials (NIP-MOFs), and the rest of the operations are consistent with the preparation process of molecularly imprinted MOFs catalyst materials.

[0039] Application examples of molecularly imprinted MOFs catalyst degrading sulfonami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com