Method and device for recovering and purifying phosphorus from sludge incineration ash

A technology of sludge incineration and electrochemistry, applied in chemical instruments and methods, phosphoric acid, inorganic chemistry, etc., can solve the problems that hinder the industrial application of the process, complex phosphorus recovery equipment, harsh reaction conditions, etc., and achieve good industrial application prospects and realize The effect of high concentration enrichment and efficient recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

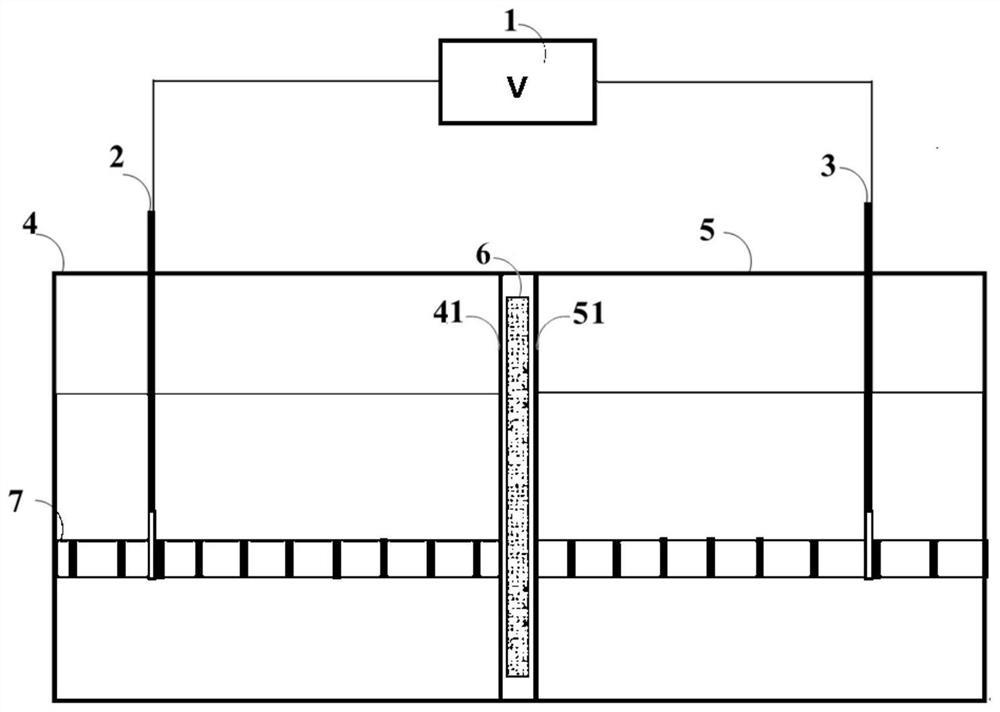

[0042] A device for recovering high-purity phosphorus from sludge incineration ash, combined with figure 1 and figure 2 shown, including:

[0043] A potentiostat 1 for providing a stable current;

[0045] An anode reaction cell 4 equipped with anolyte, in which an anode 2 is inserted, the anode reaction cell 4 is a detachable reaction cell;

[0046] A cathode reaction tank 5 equipped with catholyte, a cathode 3 is inserted in the cathode reaction tank 5, and the cathode reaction tank 5 is a detachable reaction tank;

[0047] Cation exchange membrane 6: the cation exchange membrane 6 is detachably arranged between the anode reaction pool 4 and the cathode reaction pool 5, on the one hand the anode reaction pool 4 and the cathode reaction pool 5 are separated by the cation exchange membrane 6, on the other hand it can The detachable installation method is also convenient for the replacement of the cation exchange membrane 6; specifically, the...

Embodiment 2

[0052] This embodiment provides a method for recovering and purifying phosphorus from sludge incineration ash, comprising the following steps:

[0053] Acid extraction: use a sulfuric acid solution with a concentration of 1moL / L as the acid agent, pickle the sludge incineration ash for 24 hours, the solid-liquid ratio of the sludge incineration ash to the sulfuric acid solution is 1:5g / mL, filter with a filter membrane after pickling Remove the insoluble solids to obtain an acid extract, which contains phosphate ions and various metal ions, and the metal ions include calcium ions, magnesium ions, aluminum ions, iron ions, copper ions, zinc ions, manganese ions, and lead ions , nickel ions, cadmium ions.

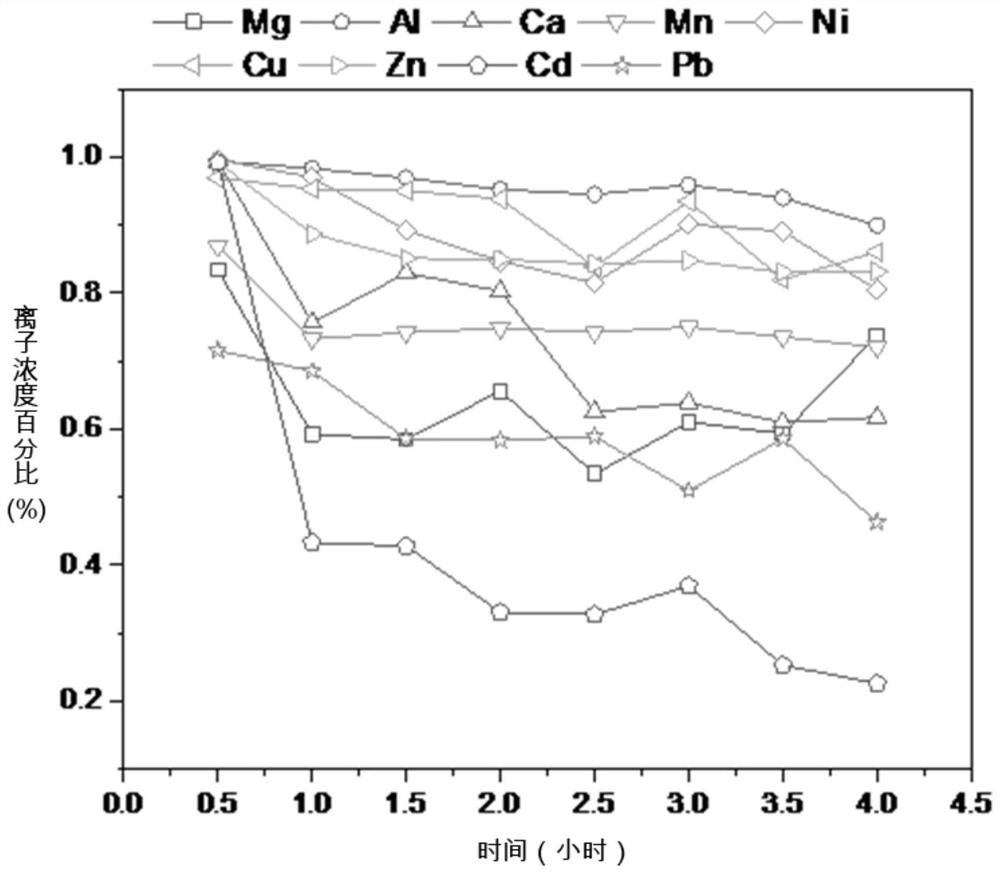

[0054] Electrochemical purification: use the filtered acid extract as the anolyte, 0.01moL / L sodium nitrate solution as the catholyte, and make the volumes of the anolyte and catholyte the same to ensure the same hydraulic pressure. 2 The platinum sheet electrodes are the an...

Embodiment 3

[0060] This embodiment provides a method for recovering and purifying phosphorus from sludge incineration ash, comprising the following steps:

[0061] Acid extraction: Use a sulfuric acid solution with a concentration of 0.2moL / L as the acid agent, pickle the sludge incineration ash for 4 hours, the solid-liquid ratio of the sludge incineration ash to the sulfuric acid solution is 1:20g / mL, use a filter membrane after pickling The insoluble solid is filtered off to obtain an acid extract, which contains phosphate ions and various metal ions.

[0062] Electrochemical purification: use the filtered acid extract as the anolyte, 0.01moL / L sodium nitrate solution as the catholyte, and make the volumes of the anolyte and catholyte the same to ensure the same hydraulic pressure. 2 The platinum sheet electrodes are the anode and the cathode, and a cation exchange membrane is set between the anolyte and the catholyte, and the electrochemical reaction is performed at a constant current...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com