Sectional heating system for plastic calendering rollers and control method of sectional heating system

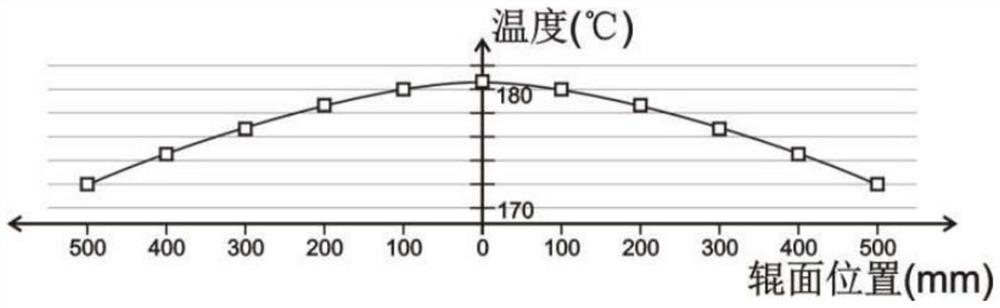

A segmented heating and heating control technology, which is applied in the field of calendering rolls, can solve the problems of flow lines on the surface of the sheet, low temperature on both sides, and inconsistent temperature, and achieve the effects of solving three highs and two lows, improving temperature control, and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

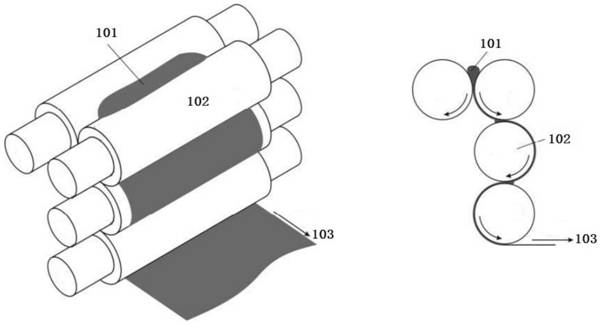

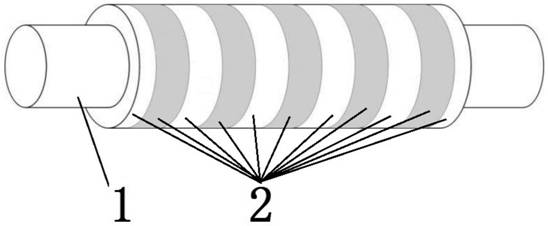

[0036] This embodiment provides a segmented heating system for plastic calendering rolls, and its component connection schematic diagram is shown in the attached Figure 4 Shown: the plastic calender is provided with a plurality of calendering rollers 1, and the roller of described calendering roller 1 is divided into a plurality of section adjacent ring-shaped heating areas 2 (the structure sees attached image 3 shown); the annular heating zone 2 is separately provided with a heating device 3 and a temperature sensor 4 for measuring the temperature of each section of the annular heating zone 2, and the heating device 3 is connected with a heating control panel 8, and the heating control panel 8 is provided with a plurality of sets, and is configured as a complete set with the heating device 3, and is connected one by one through the heating electric slip ring 5; the temperature measurement sensor 4 is connected with the temperature controller 7 through the temperature measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com