Hot-molten metal micro-droplet direct on-demand printing mechanism based on piezoelectric micro jetting

A printing mechanism and micro-droplet technology, applied in the direction of improving process efficiency, additive processing, and improving energy efficiency, can solve the problems of low precision of molten metal droplet printing, complicated manufacturing process, and low material utilization rate. Achieve the effects of low cost, simple and compact structure, and no electromagnetic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] It should be noted that the embodiments of the present invention and the features in the embodiments can be combined with each other if there is no conflict.

[0038] Hereinafter, the present invention will be described in detail with reference to the drawings and in conjunction with the embodiments.

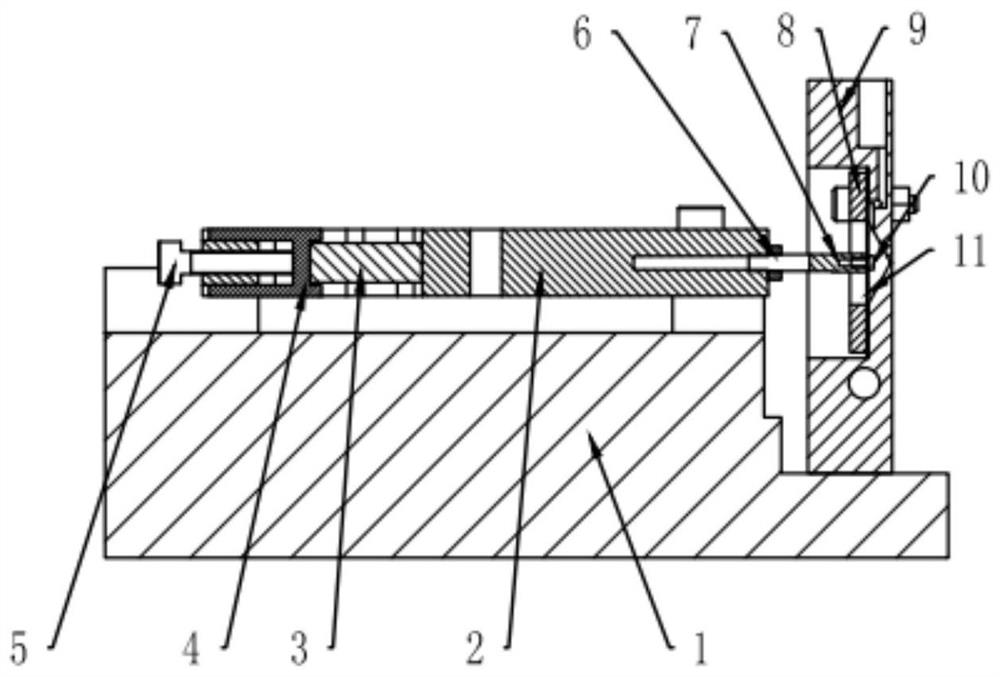

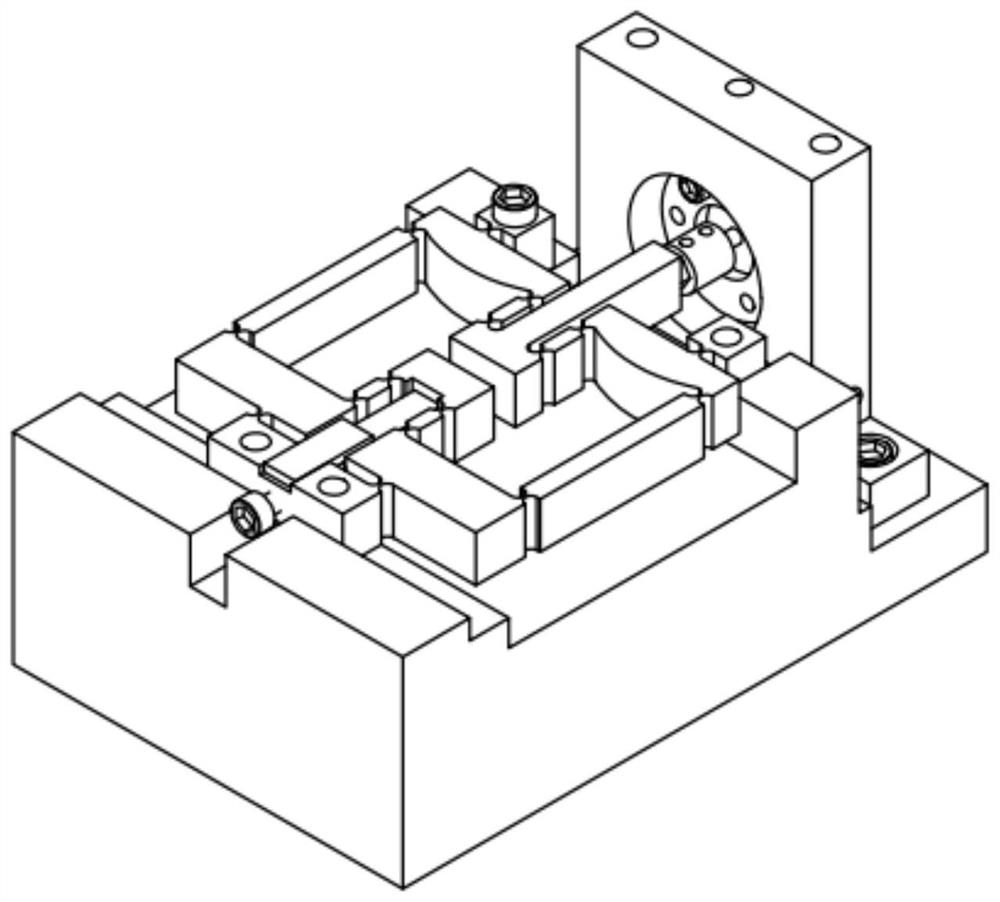

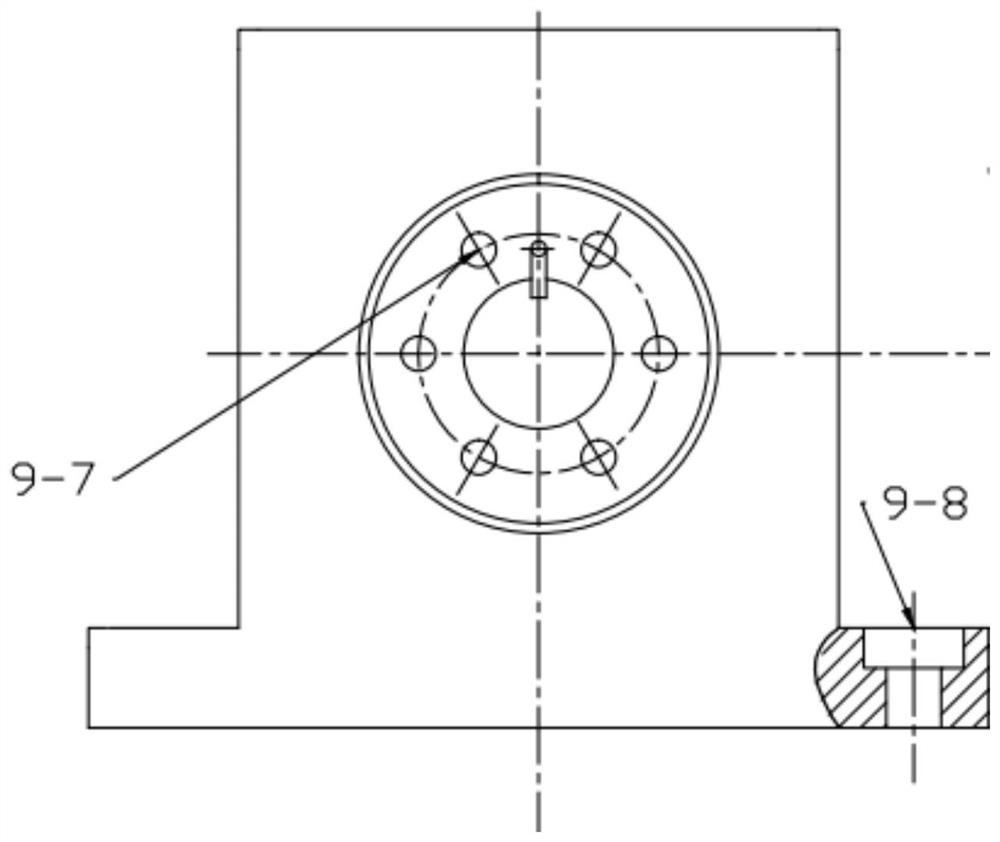

[0039] Such as Figure 1-Figure 8 As shown, a direct-on-demand printing mechanism for hot-melt metal micro-droplets based on piezoelectric micro-jets includes a base 1, a flexible displacement amplification mechanism 2, a piezoelectric stack 3, a guide compression block 4, a push rod 7, The rigid compression ring 8, the hot-melt cavity structure 9 and the elastic diaphragm 11, the flexible displacement amplification mechanism 2 and the hot-melt cavity structure 9 are all fixed on the base 1 by bolts, in the hot-melt cavity The center of the structure 9 is provided with a cone-shaped cavity 9-5, and the opening of the cone-shaped cavity 9-5 is arranged toward the output end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com