Raw material graded screening device used for flour processing

A technology for grading and screening raw materials, which is applied in the direction of separating solids from solids with airflow, filtering, and solid separation. It can solve the problems of wheat spilling, screening, and affecting the quality of screening, and achieve increased stability and high-efficiency screening. The effect of sub-cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

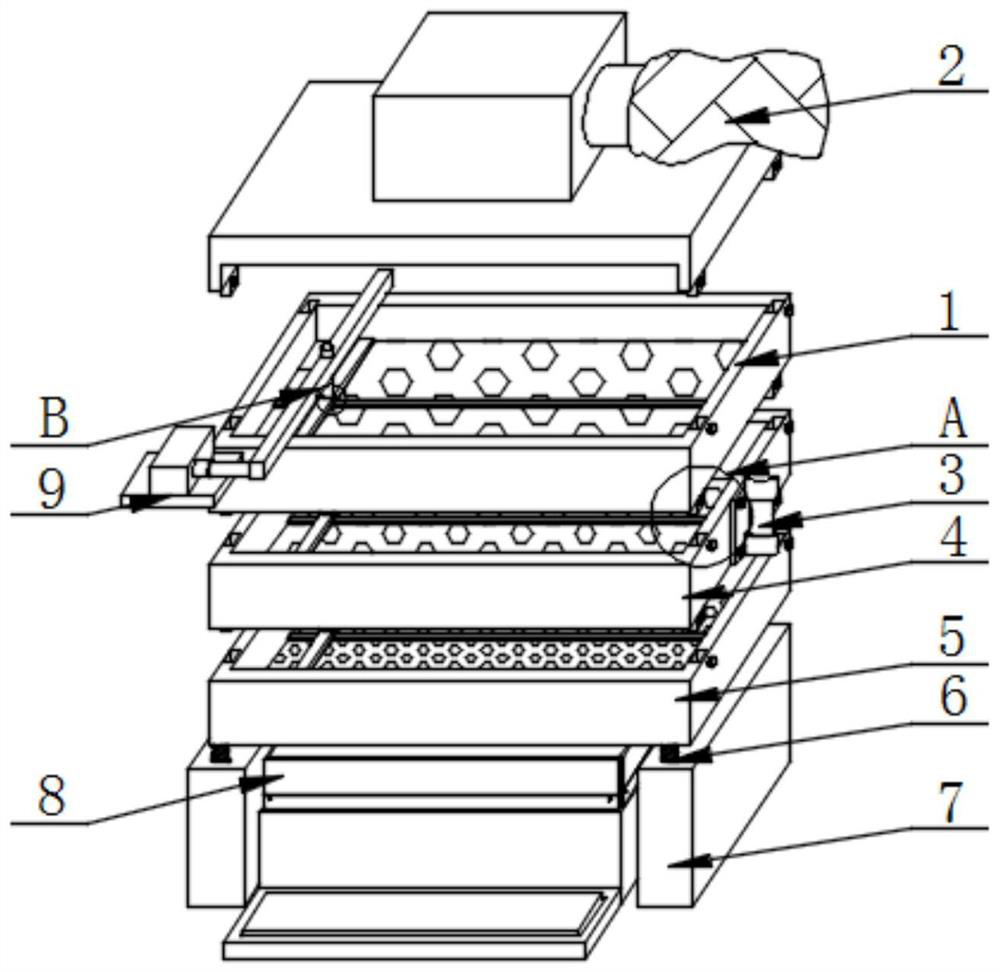

[0027] see Figure 1~6 , in an embodiment of the present invention, a raw material grading and screening device for flour processing includes a first screen 1, a second screen 4 and a third screen 5, and the second screen 4 is clamped with a first Screen 1, and the third screen 5 is clamped under the second screen 4, the first bayonet pin 13 is installed on the lower surface of the first screen 1 and the second screen 4, the second screen 4 and The upper surface of the third screen 5 is provided with a first slot 12, and the inside of the first bayonet 13 is provided with a first screw hole 10, and the first bayonet 13 is installed symmetrically in pairs on the lower surface of the first screen 1. There are four, and the first bayonet pin 13 and the first bayonet groove 12 fit each other, the first bolt 11 and the first screw hole 10 are connected by threads, the first screen 1, the second screen 4 and the third screen Both sides of the 5 are provided with first bolts 11, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com