LED driving power supply

A technology of LED drive and DC power supply, applied in the direction of electrical components, etc., which can solve the problems of large parasitic capacitance between circuit board and metal layer, increased cost, harmful stroboscopic problems of eyes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

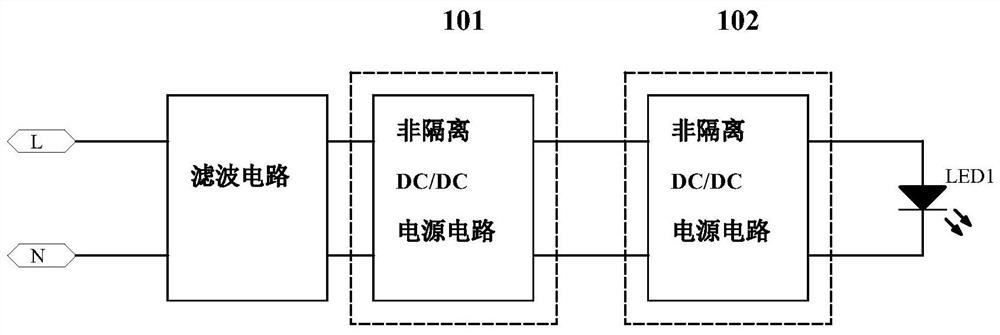

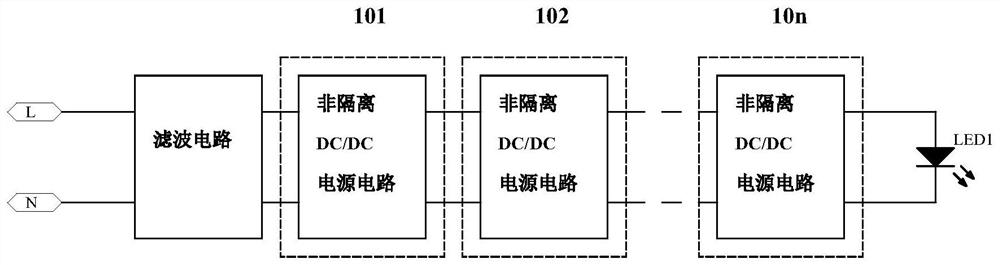

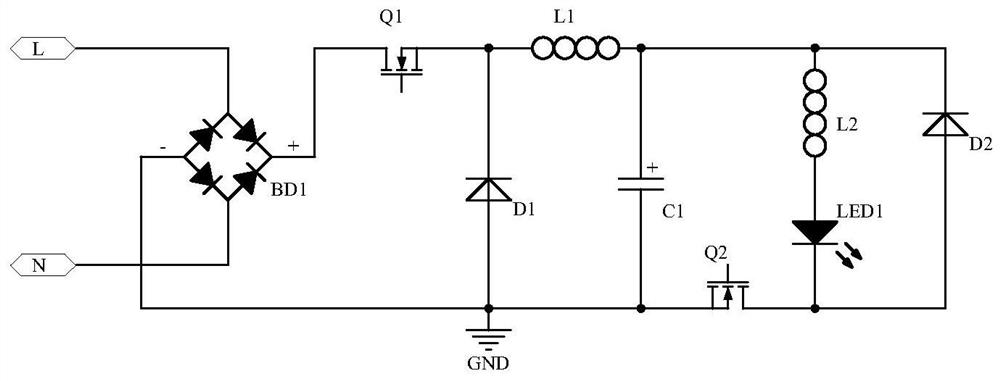

[0056] image 3 For the circuit principle of the first embodiment of the present invention, for figure 1 a specific circuit.

[0057] The filter circuit is a rectifier bridge BD1, the positive input terminal of the rectifier bridge BD1 is used to connect to the L line of the grid, the negative input terminal is used to connect to the N line of the grid, and the positive output terminal is connected to the positive input terminal of the non-isolated DC / DC power supply circuit 101, The negative output terminal is connected to the negative input terminal of the non-isolated DC / DC power supply circuit 101;

[0058] The non-isolated DC / DC power supply circuit 101 is a buck circuit, including a switch tube Q1, a diode D1, an inductor L1, and a capacitor C1. The drain of the switch tube Q1 is the positive input terminal of the non-isolated DC / DC power supply circuit 101, and the source of the switch tube Q1 is One end of the inductance L1 is connected to the cathode of the diode D1...

no. 2 example

[0069] Figure 4 It is the circuit principle of the second embodiment of the present invention, and the difference from the first embodiment is that the non-isolated DC / DC power supply circuit 101 is a BUCK-BOOST circuit, including a switch tube Q1, a diode D1, an inductor L1 and a capacitor C1, and a switch The drain of the tube Q1 is the positive input terminal of the non-isolated DC / DC power supply circuit 101, the source of the switch tube Q1 is connected to one end of the inductor L1 and the cathode of the diode D1 at the same time, and the anode of the diode D1 is connected to one end of the capacitor C1 to be non-isolated. The positive output end of the DC / DC power supply circuit 101, the other end of the inductor L1 and the other end of the capacitor C1 are connected to both the negative input end of the non-isolated DC / DC power supply circuit 101 and the negative output of the non-isolated DC / DC power supply circuit 101 end.

[0070] The working principle of this emb...

no. 3 example

[0078] Figure 5 It is the circuit principle of the third embodiment of the present invention. The difference between this embodiment and the second embodiment is that the non-isolated DC / DC power supply circuit 102 is a BUCK circuit, including a switch tube Q2, a diode D2, an inductor L2 and a capacitor C2. After the anode of the diode D2 is connected to one end of the capacitor C2, it is simultaneously the positive input terminal of the non-isolated DC / DC power supply circuit 102 and the positive output terminal of the non-isolated DC / DC power supply circuit 102, and the cathode of the diode D2 is simultaneously connected to the source of the switch tube Q2 pole and one end of the inductor L2, the drain of the switch tube Q2 is the negative input end of the non-isolated DC / DC power supply circuit 102, and the other end of the inductor L2 is the negative output end of the non-isolated DC / DC power supply circuit 102.

[0079] The working principle of this embodiment is as foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com