Film acoustic metamaterial of honeycomb flanged structure

A technology of acoustic metamaterials and thin films, applied in the field of acoustic metamaterials, can solve the problem that low-frequency noise is difficult to effectively isolate, and achieve the effect of light structure and improved structure layout efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation manners of the present invention will be described in further detail below in conjunction with the technical solutions and accompanying drawings.

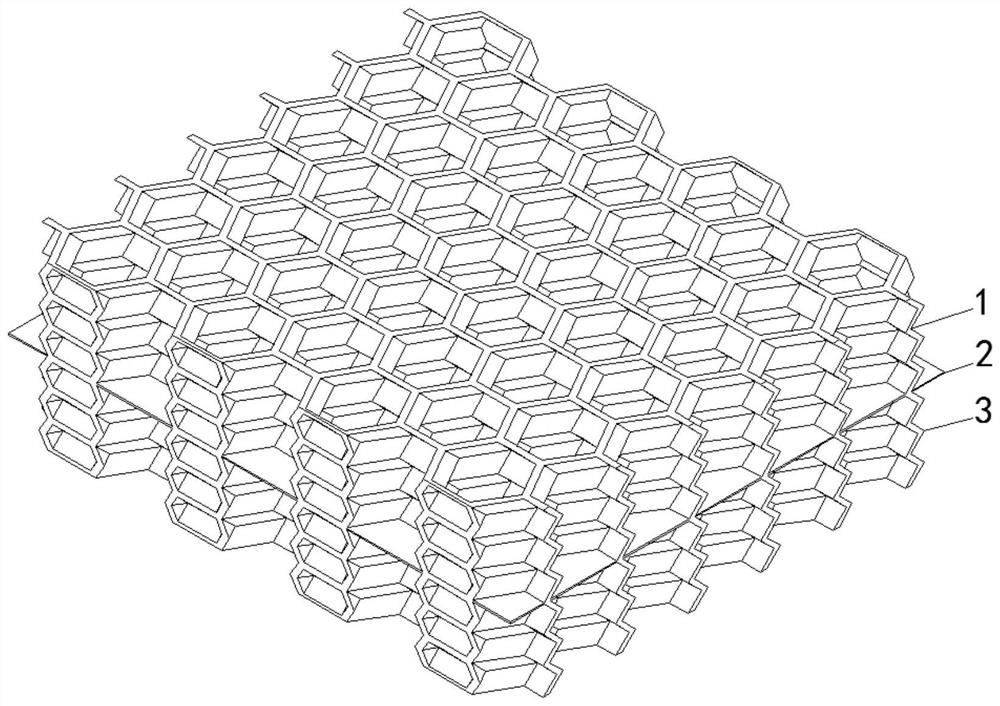

[0038] figure 1 Shown is an embodiment of a thin-film acoustic metamaterial with a honeycomb folded-edge structure according to the present invention.

[0039] The invention adds a layer of thin film on the basis of the variable-angle folded frame structure, and utilizes sound waves to resonate with the cavity and the thin film, thereby achieving good sound insulation effect in the low frequency range.

[0040] figure 1 It is a multicellular structure of the acoustic metamaterial, including an upper frame 1 , a middle membrane 2 and a lower frame 3 .

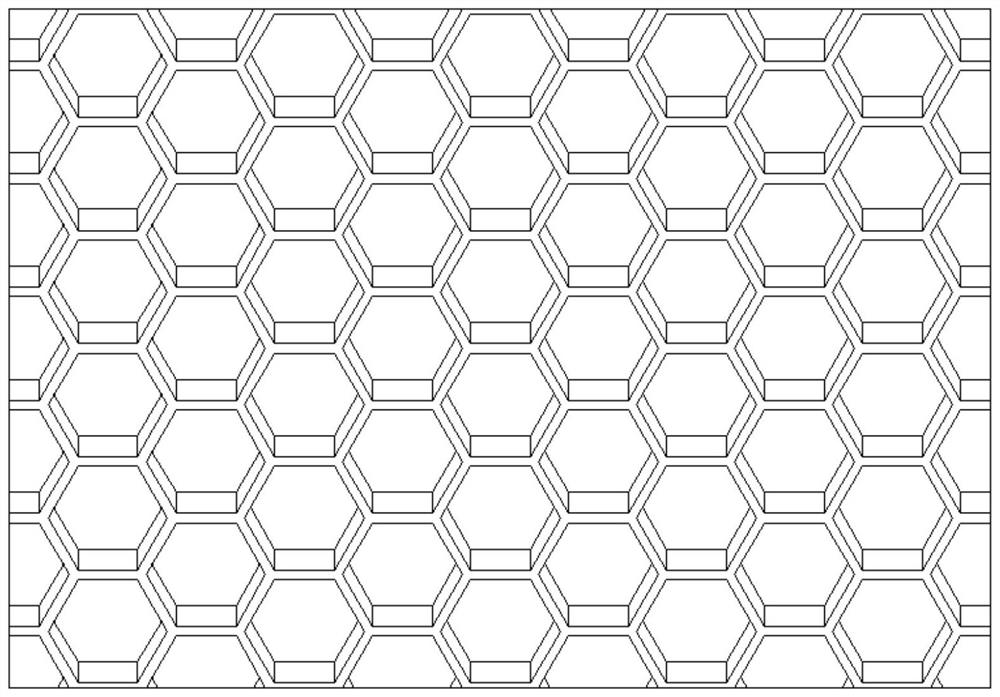

[0041] figure 2 It is a top view of the multicellular structure of the acoustic metamaterial, and its section is a regular hexagon with side length a.

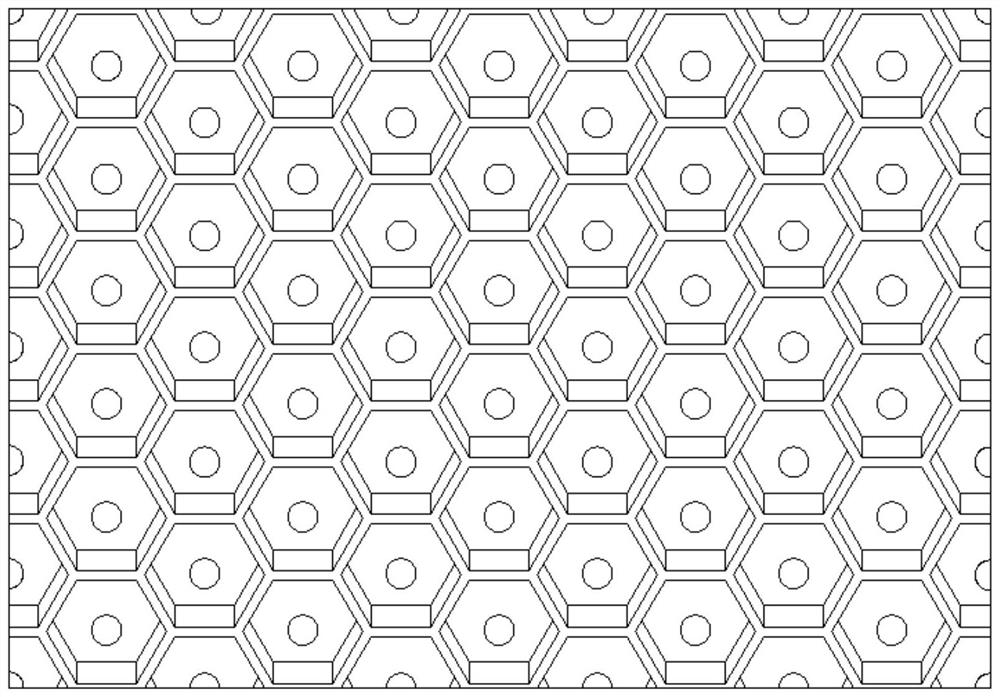

[0042] image 3 is the top view of the multi-cell model of the acoustic metamaterial aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com