A preparation method of a grating with continuously changing diffraction efficiency

A diffraction efficiency and grating technology, applied in the field of waveguide optical diffraction elements, can solve problems such as poor uniformity of the outgoing beam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

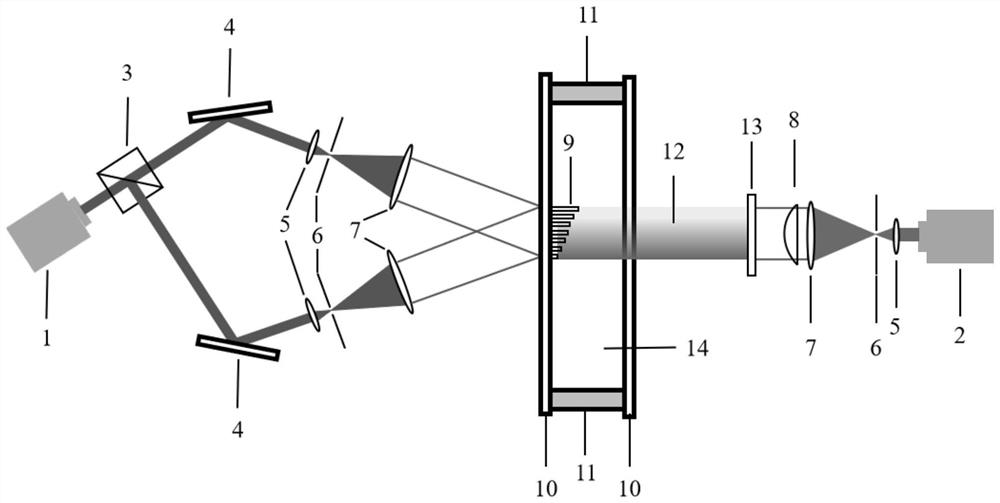

[0039] Such as figure 1 and Figure 7 As shown, after the light with a wavelength a is emitted from the laser 1, two beams of light are separated by the beam splitter 3, and the two beams of light are respectively reflected by the mirror 4 to form a certain angle, and then pass through the beam expander lens 5, The filtering pinhole 6 and the collimating lens 7 interfere with each other after beam expansion, filtering and collimation.

[0040] After the light with wavelength b is emitted from the laser 2, after passing through the beam expander lens 5, the filter pinhole 6 and the collimator lens 7, after beam expansion, filtering and collimation, the light intensity of the obtained expanded beam is in a Gaussian distribution, In order to obtain a light beam with uniform distribution of light intensity, it should pass through the shaping lens 8 to make the light intensity uniform. The continuously variable transmittance neutral filter 13 can be superimposed on the uniformly ...

Embodiment 2

[0052] Such as Figure 4 and Figure 7 As shown, after the light with a wavelength a is emitted from the laser 1, two beams of light are separated by the beam splitter 3, and the two beams of light are respectively reflected by the mirror 4 to form a certain angle, and then pass through the beam expander lens 5, The filtering pinhole 6 and the collimating lens 7 interfere with each other after beam expansion, filtering and collimation.

[0053] After the light with wavelength b is emitted from the laser 2, after passing through the beam expander lens 5, the filter pinhole 6 and the collimator lens 7, after beam expansion, filtering and collimation, the light intensity of the obtained expanded beam is in a Gaussian distribution, In order to obtain a light beam with uniform distribution of light intensity, it should pass through the shaping lens 8 to make the light intensity uniform. The continuously variable transmittance neutral filter 13 can be superimposed on the uniformly...

Embodiment 3

[0071] Such as Figure 8 As shown, after the light with a wavelength a is emitted from the laser 1, it passes through the beam expander lens 5, the filter pinhole 6 and the collimator lens 7 for beam expansion, filtering and collimation, and then passes through the wedge-shaped plate 15, and then generates Equal thickness interference.

[0072] After the light with wavelength b is emitted from the laser 2, after passing through the beam expander lens 5, the filter pinhole 6 and the collimator lens 7, after beam expansion, filtering and collimation, the light intensity of the obtained expanded beam is in a Gaussian distribution, In order to obtain a light beam with uniform distribution of light intensity, it should pass through the shaping lens 8 to make the light intensity uniform. The continuously variable transmittance neutral filter 13 can be superimposed on the uniformly distributed light beam with wavelength b to obtain the light 12 with continuously changing light inten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com