High-temperature-resistant capsule gel breaker for fracturing and preparation method thereof

A capsule breaker and high temperature resistant technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problem of high cost, and achieve the effects of easy control of breaking time, good water resistance and delayed breaking performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

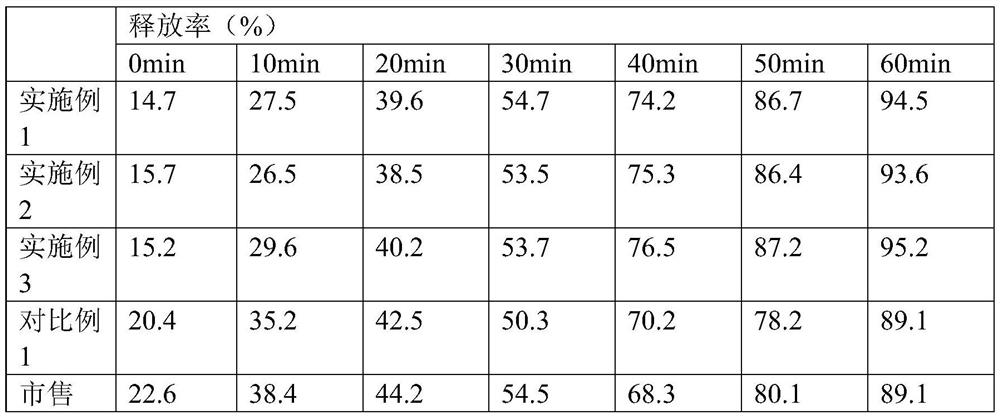

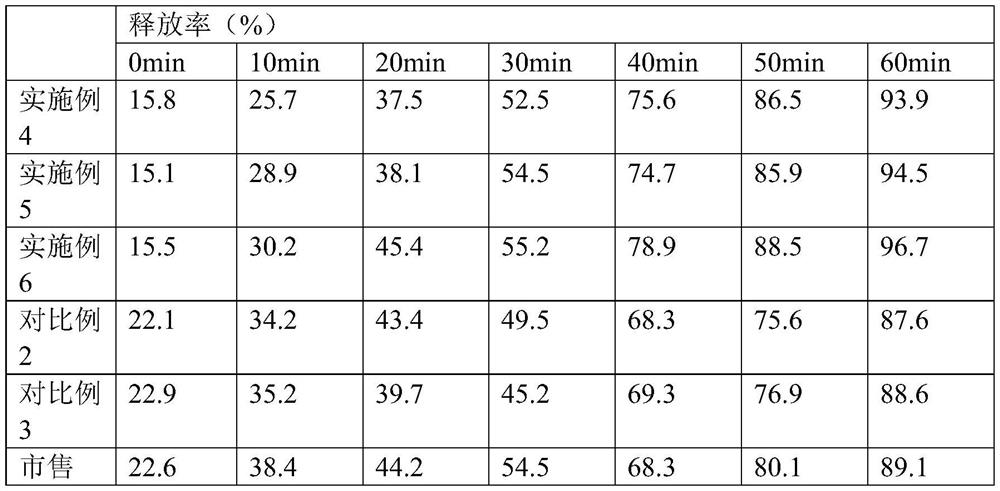

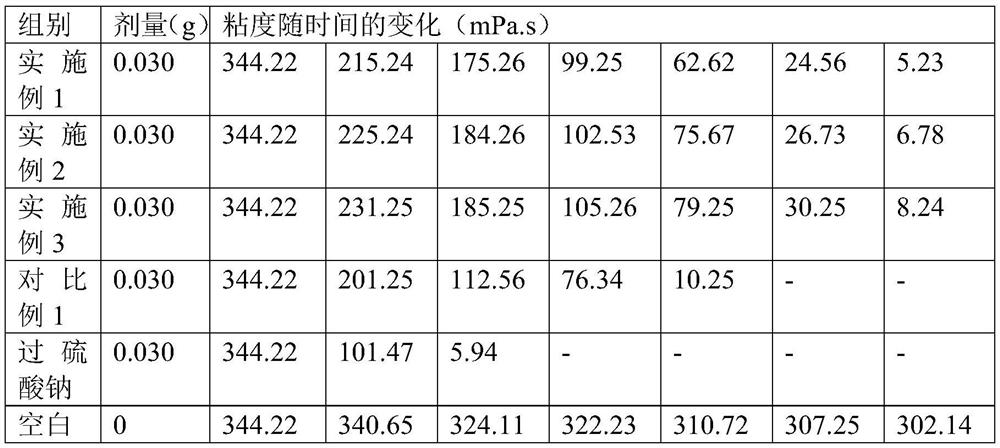

Examples

Embodiment 1

[0031] Embodiment 1 Capsule breaker for high temperature fracturing

[0032] In the capsule gel breaker (capsule coat is capsule coat A), potassium persulfate accounts for 30% of the total mass of the capsule gel breaker, polyvinyl alcohol accounts for 5% of the total mass of the capsule gel breaker, and lecithin accounts for 5% of the total mass of the capsule gel breaker. 1% of the total mass, and the balance is the coating material.

[0033] The preparation method of high temperature resistant capsule gel breaker:

[0034] S1. After mixing potassium persulfate, polyvinyl alcohol, and lecithin uniformly in proportion, add them into water according to the solid-to-liquid ratio of 1:1g / mL, and disperse them uniformly by ultrasonic at an ultrasonic power of 1000W to obtain a feed liquid;

[0035] S2. Dissolve 100g of linear polystyrene, 15g of polyisopropylacrylamide, and 5g of p-bis(chloromethyl)benzene in 200mL of ethyl acetate-acetone mixture (the volume ratio of ethyl acet...

Embodiment 2

[0038] Example 2 Capsule gel breaker for high temperature resistant fracturing

[0039] In the capsule gel breaker (capsule coat is capsule coat A), the cellulose glycoside bond-specific enzyme accounts for 70% of the total mass of the capsule gel breaker, polyvinylpyrrolidone accounts for 10% of the total mass of the capsule gel breaker, and octylbenzene Cycloxanol accounts for 6% of the total mass of the capsule gel breaker, and the balance is the capsule coating material;

[0040] The preparation method of high temperature resistant capsule gel breaker:

[0041] S1. After mixing the cellulose glucoside-specific enzyme, polyvinylpyrrolidone, and octoxynol in proportion, add it into water according to the solid-to-liquid ratio of 1:3g / mL, and disperse until uniform under the ultrasonic power of 2000W. get liquid;

[0042] S2. Dissolve 100g of linear polystyrene, 35g of polyisopropylacrylamide, and 12g of p-bis(chloromethyl)benzene in 200mL of ethyl acetate-acetone mixture (...

Embodiment 3

[0045] Example 3 Capsule gel breaker for high temperature resistant fracturing

[0046] In the capsule gel breaker (capsule coat is capsule coat A), sodium persulfate accounts for 50% of the total mass of the capsule gel breaker, polyvinyl alcohol accounts for 7% of the total mass of the capsule gel breaker, and polyacrylamide accounts for 50% of the total mass of the capsule gel breaker. 3% of the total mass of the agent, and the balance is the capsule coating material.

[0047] The preparation method of high temperature resistant capsule gel breaker:

[0048] S1. After mixing sodium persulfate, polyvinyl alcohol, and polyacrylamide uniformly in proportion, add them into water according to the solid-to-liquid ratio of 1:2g / mL, and disperse them until uniform by ultrasonic at an ultrasonic power of 1500W to obtain a material liquid;

[0049] S2. Dissolve 100g of linear polystyrene, 25g of polyisopropylacrylamide, and 7g of p-bis(chloromethyl)benzene in 200mL of ethyl acetate-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com