Preparation method and system for producing important precursor ATC of L-cysteine by enzymic method

A technology of cysteine and preparation equipment, which is applied in the field of biomedicine, can solve the problem of only 70%-80%, and achieve the effects of low environmental pollution, high comprehensive yield, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

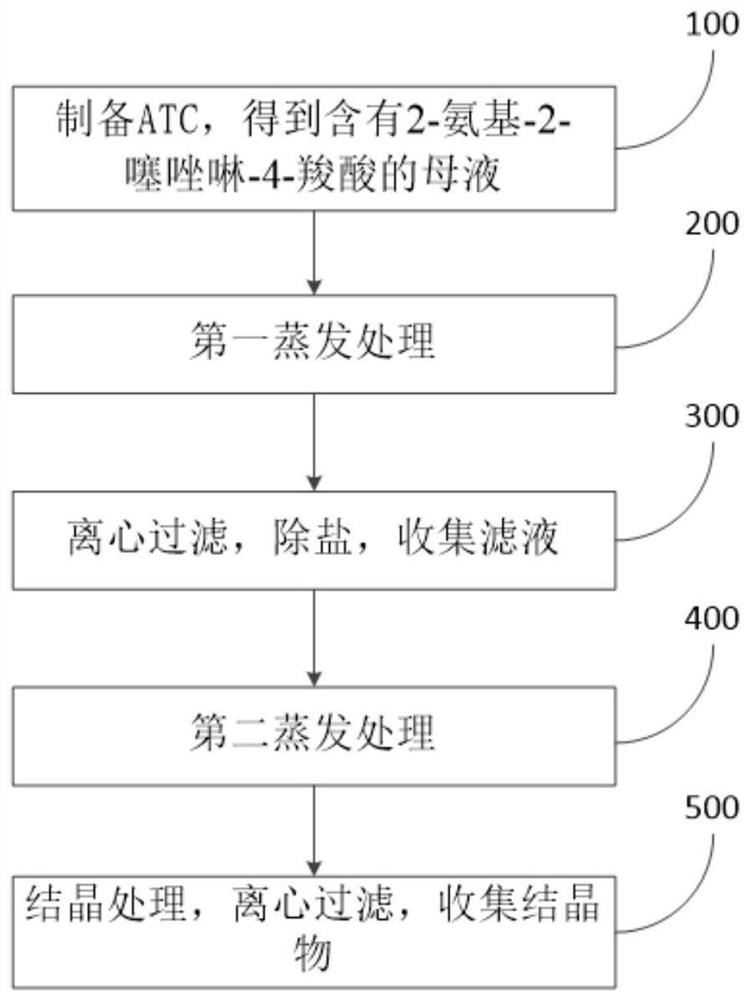

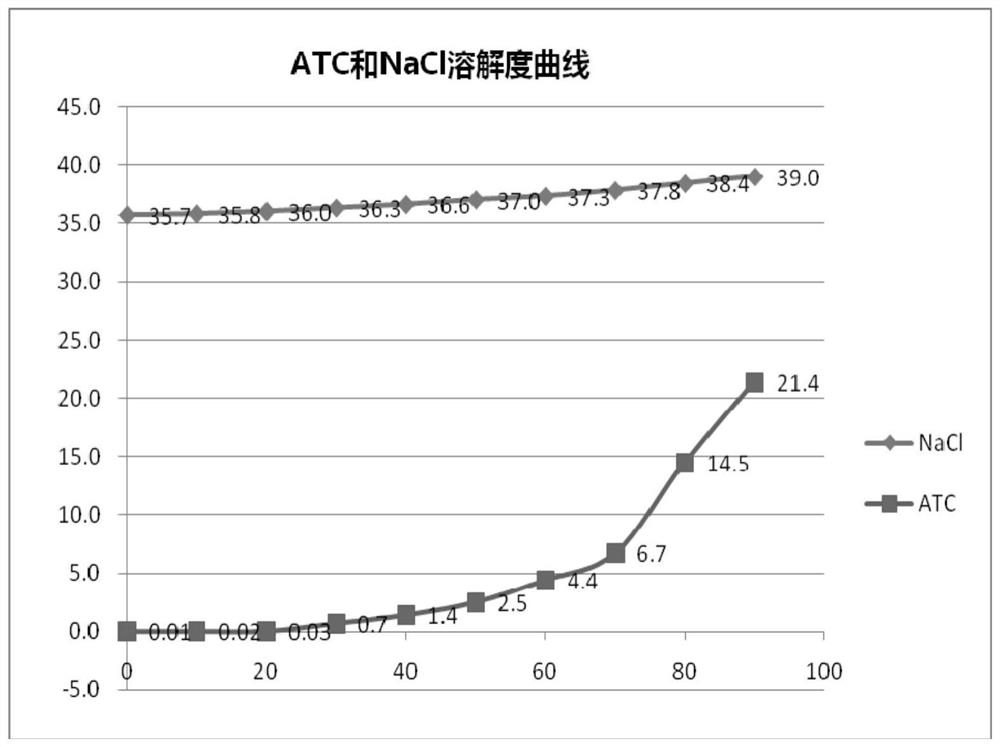

Method used

Image

Examples

Embodiment 1

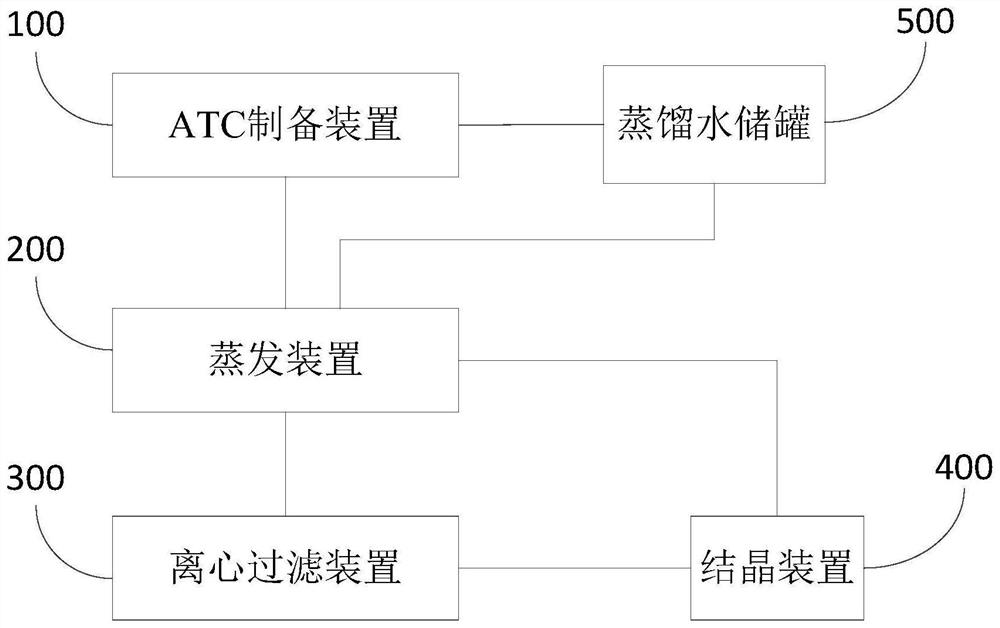

[0083] In this example, ATC was prepared according to the following method, the system see Figure 4 .

[0084] 1. Turn on the refrigeration device to cool down, add 200kg of methyl dichloropropionate into the 2T reaction tank, add 300kg of tap water, the liquid volume is about 500L, cool down to 0°C, slowly add 32% sodium hydroxide solution dropwise, the reaction temperature The temperature is controlled below 10°C, and the dropwise addition time is about 1.5-2h. After the dropwise addition is completed, stir slowly for 30 minutes. Then add about 100kg of thiourea, continue to control the reaction temperature below 10°C, slowly add concentrated hydrochloric acid dropwise, continue to keep the temperature below 10°C, dropwise for 30-50min, after the addition is complete, heat up to 30-35°C and keep warm Reaction 4.5-5h. After the heat preservation is completed, continue to slowly add the sodium carbonate solution dropwise for 1.5-2 hours. After the dropwise addition is compl...

Embodiment 2

[0089] In this example, ATC was prepared according to the following method.

[0090] 1. Turn on the refrigeration device to cool down, add 200kg of methyl dichloropropionate into the 2T reaction tank, add 300kg of tap water, the liquid volume is about 500L, cool down to 0°C, slowly add 32% sodium hydroxide solution dropwise, the reaction temperature The temperature is controlled below 10°C, and the dropwise addition time is about 1.5-2h. After the dropwise addition is completed, stir slowly for 30 minutes. Then add about 100kg of thiourea, continue to control the reaction temperature below 10°C, slowly add concentrated hydrochloric acid dropwise, continue to keep the temperature below 10°C, dropwise for 30-50min, after the addition is complete, heat up to 30-35°C and keep warm Reaction 4.5-5h. After the heat preservation is completed, continue to slowly add the sodium carbonate solution dropwise for 1.5-2 hours. After the dropwise addition is completed, raise the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com