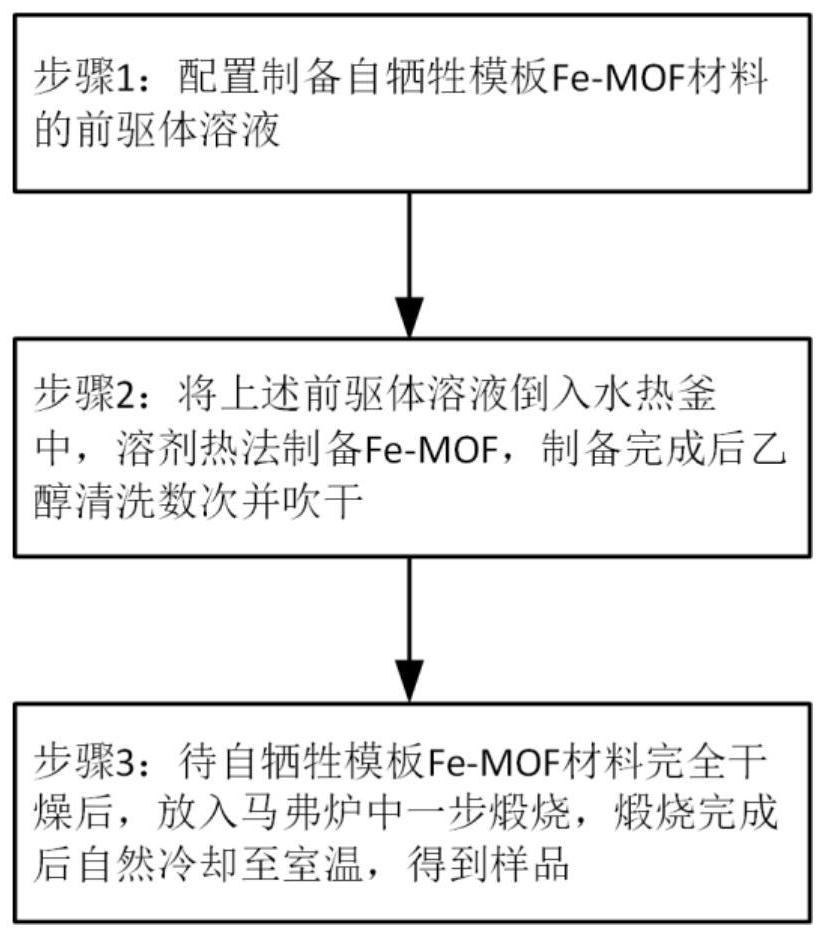

Gas-sensitive nano material based on carbon particle modified mesoporous iron oxide nanorod structure as well as preparation process and application of gas-sensitive nano material

A technology of nano-iron oxide and preparation process, which is applied in the direction of nanotechnology, iron oxide, iron oxide/iron hydroxide, etc. for materials and surface science, which can solve problems such as human health damage, and achieve long-term stability and service life Improvement, chemical stability and thermal stability, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Add 0.32 g of F127 and 0.358 g of ferric chloride hexahydrate into 30 mL of deionized water and mix well to obtain mixed solution A;

[0038] (2) After stirring the mixed solution A prepared in step (1) for 1 hour, inject 1.2mL of anhydrous acetic acid to obtain the mixed solution B;

[0039] (3) After stirring the mixed solution B prepared in step (2) for 1 hour, add 0.12 g of 2-aminoterephthalic acid solid to obtain mixed solution C;

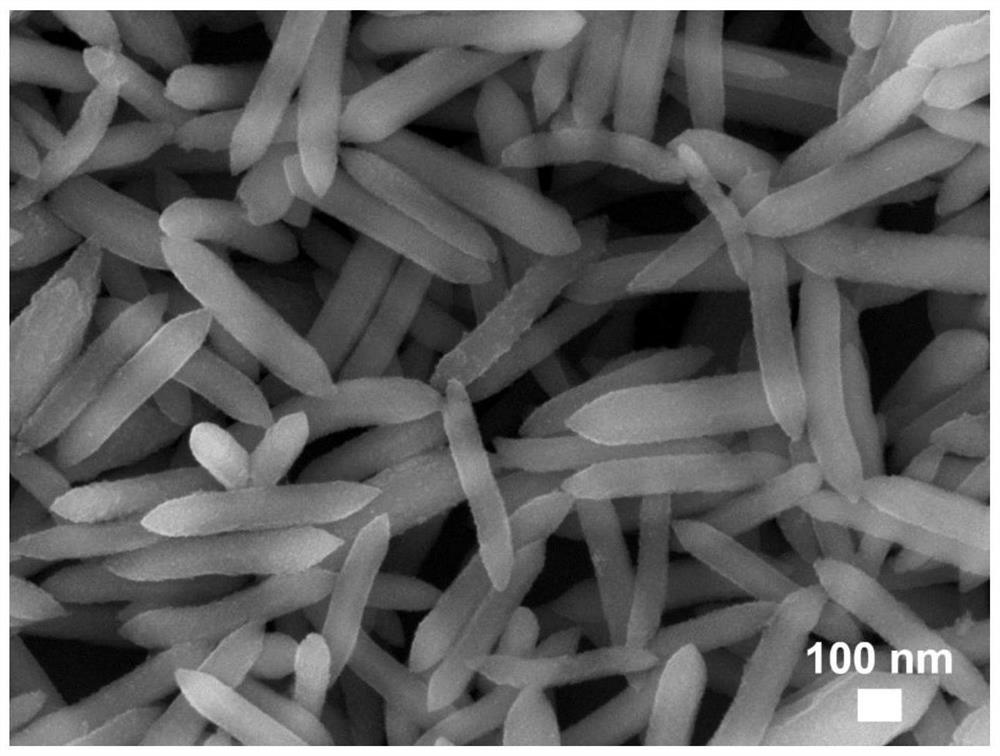

[0040] (4) After stirring the mixed solution C prepared in step (3) for 2 hours, pour it into a hydrothermal kettle as a precursor solution, and conduct a solvothermal reaction at 110°C for 24 hours. After completion, wash it with ethanol several times and dry it. , to obtain the self-sacrificing template material Fe-MOF nanorods, and its SEM characterization is as follows figure 2 As shown, it can be seen that the average diameter of Fe-MOF nanorods is about 86nm, and the average length is about 540nm;

[0041] (5) After the self-...

Embodiment 2

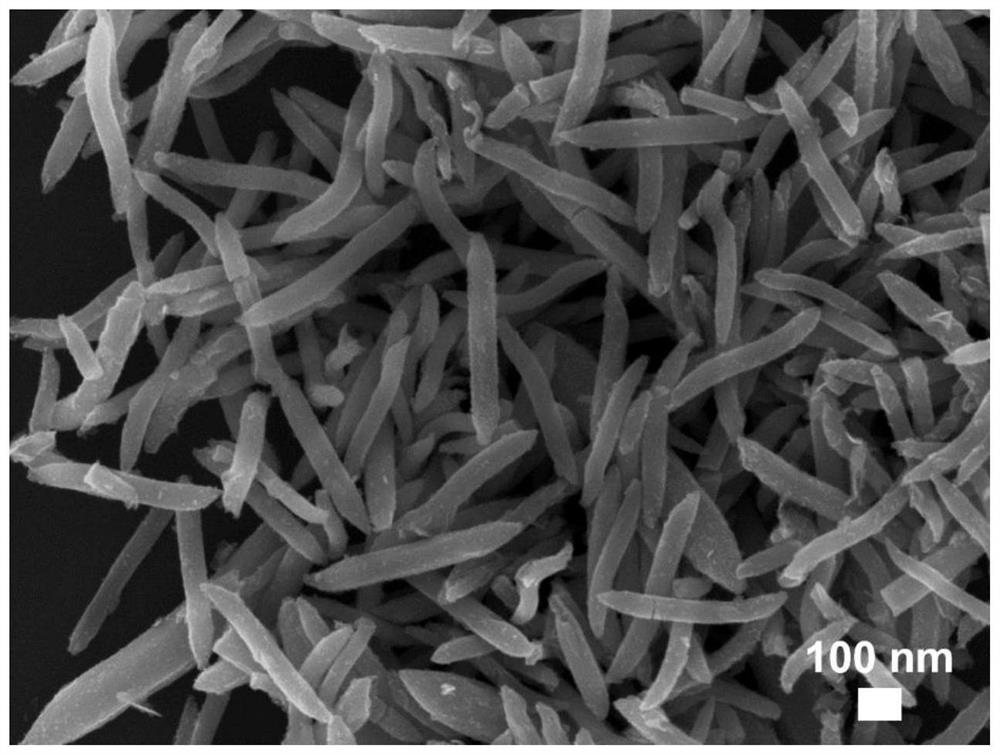

[0046] Similar to Example 1, the difference is that the calcination temperature in one-step calcination is 350°C. The SEM characterization of the obtained carbon particle-modified mesoporous iron oxide nanorods is shown in Figure 7 As shown, the average diameter of mesoporous iron oxide nanorods is about 52 nm, the average length is about 436 nm, the average diameter of mesoporous particles is about 5 nm, and the average diameter of carbon particles is about 5 nm. , the average diameter and average length of the carbon particle-modified mesoporous iron oxide nanorods obtained by calcination are correspondingly shortened, the mesopore size is increased, while the average size of carbon particles is reduced and the surface distribution concentration is reduced. . The carbon particle-modified mesoporous iron oxide nanorods calcined at 350 °C were also tested for acetone gas sensing performance, and the results are as follows: Figure 8 As shown, although its response is slight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com