Preparation process of flame-retardant sound-insulation rubber pad

A preparation process and technology for rubber pads are applied in the field of preparation technology of flame-retardant and sound-proof rubber pads, which can solve the problems of poor compactness, increased material thickness, and multiple spaces, and achieve the effects of excellent sound insulation and sound insulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

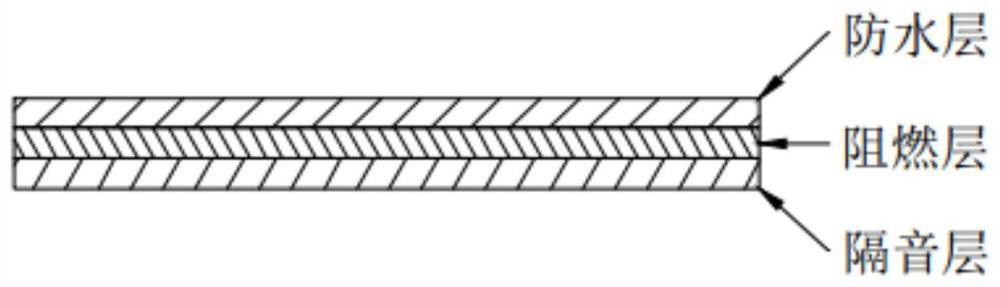

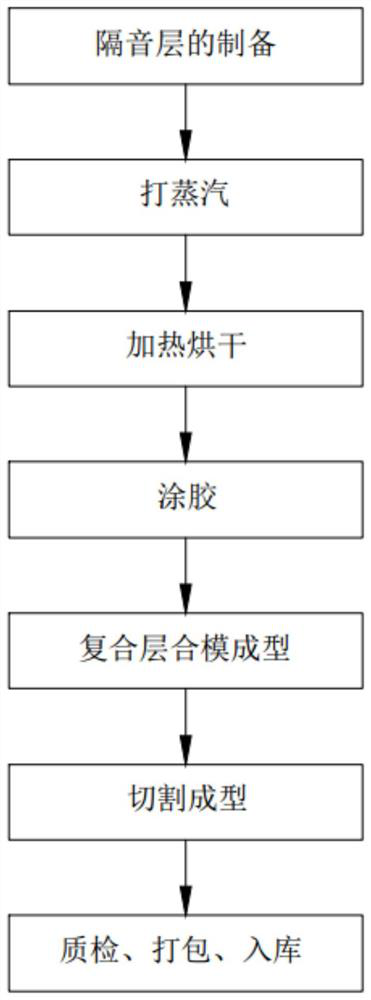

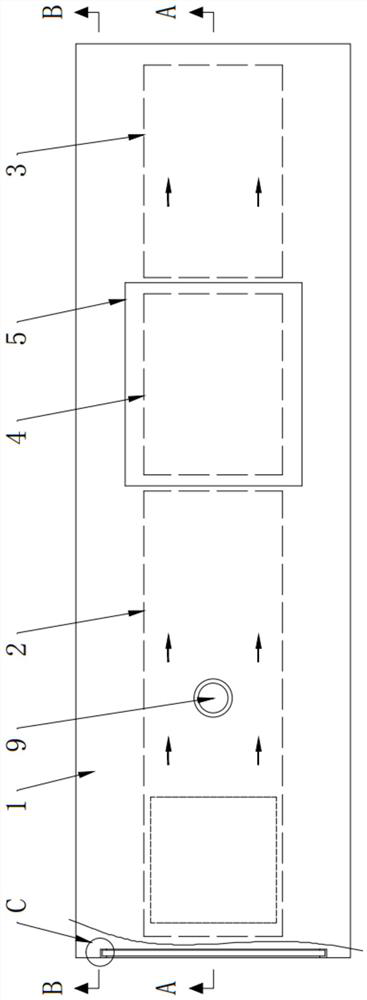

[0038] Such as figure 1 and figure 2 Shown, a kind of preparation technology of flame-retardant soundproof rubber pad comprises the following steps:

[0039] The above-mentioned flame-retardant and sound-insulating rubber mat includes a sound-insulating layer, a flame-retardant layer and a waterproof layer arranged sequentially from bottom to top;

[0040] The sound-insulating layer is composed of PET and PP at a mass ratio of 5:7; the flame-retardant layer is composed of the following raw materials in parts by weight: 10 parts of silicon dioxide, 15 parts of cross-linked polyethylene, and 6 parts of polyacrylamide , 2 parts of talcum powder, 1 part of organic fiber; the waterproof layer is composed of the following raw materials in parts by weight: 5 parts of acrylate, 30 parts of quartz sand, 1 part of hydroxypropyl methylcellulose ether, 2 parts of asphalt, nano 2 parts of graphene;

[0041]The preparation process of the above-mentioned flame-retardant and sound-insulat...

Embodiment 2

[0050] The above-mentioned flame-retardant and sound-insulating rubber mat includes a sound-insulating layer, a flame-retardant layer and a waterproof layer arranged sequentially from bottom to top;

[0051] The sound insulation layer is composed of PET and PP at a mass ratio of 5:8; the flame retardant layer is composed of the following raw materials in parts by weight: 12 parts of silicon dioxide, 18 parts of cross-linked polyethylene, and 9 parts of polyacrylamide , 4 parts of talcum powder, 2 parts of organic fiber; the waterproof layer is composed of the following raw materials in parts by weight: 7 parts of acrylate, 35 parts of quartz sand, 1 part of hydroxypropyl methylcellulose ether, 3 parts of asphalt, nano 3 parts of graphene;

[0052] The preparation process of the above-mentioned flame-retardant and sound-insulating rubber mat is as follows:

[0053] (1) Put PET and PP into the hopper of the melt-blown machine according to the formula, and they are in a molten s...

Embodiment 3

[0061] A preparation process for a flame-retardant sound-insulating rubber mat, comprising the steps of:

[0062] The above-mentioned flame-retardant and sound-insulating rubber mat includes a sound-insulating layer, a flame-retardant layer and a waterproof layer arranged sequentially from bottom to top;

[0063] The sound insulation layer is composed of PET and PP at a mass ratio of 5:9; the flame retardant layer is composed of the following raw materials in parts by weight: 15 parts of silicon dioxide, 20 parts of cross-linked polyethylene, and 12 parts of polyacrylamide , 5 parts of talc powder, 2 parts of organic fiber; the waterproof layer is composed of the following raw materials in parts by weight: 10 parts of acrylate, 40 parts of quartz sand, 2 parts of hydroxypropyl methylcellulose ether, 5 parts of asphalt, nano 5 parts of graphene;

[0064] The preparation process of the above-mentioned flame-retardant and sound-insulating rubber mat is as follows:

[0065] (1) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com